Die Casting Process: Definition, Components, Types, Working Principle, Advantages, Disadvantages, and Applications [PDF]

Die Casting Process is different from the Sand casting process with respect to the mold only. In Sand Casting Process, the mould is made up of Sand whereas, in this process, the mold is made up of Metal.

Most die castings are made from non-ferrous metals specifically aluminium, zinc, lead, copper pewter, and tin-based alloys.

So let me discuss the overview of Die Casting manufacturing process.

What is the Die Casting Process?

Die Casting Process is a metal casting process that is characterized by forcing the molten metal into a mold cavity under the application of high pressure or under gravity. Because of the metal mold, the same mold can be used for producing the infinite number of castings, hence the process is also called a Permanent Mold Casting Process.

Example for the process of Die casting process includes Die Steel or Tool Steel.

The mold is made by using metal which has been machined into a shape similar to an injection molding process.

Properties of Die Casting Process:

The properties exhibited after die casting process is as follows.

Surface Finish:

On the metal molds, the excellent surface finish can be produced. Therefore, the surface finish produced in the casting is excellent.

Machining:

Here, no machining is required in the casting process and close dimensional tolerances can be produced directly.

Thermal Conductivity:

The thermal conductivity of metal molds is higher. Hence the surface hardening heat treatment effect is taking place.

Porosity:

There is no porosity property of the mold hence through Risers must be used.

Melting Point Metals:

Because of the problem of the melting of the metal mold, this process is used only for producing castings with low melting point metals.

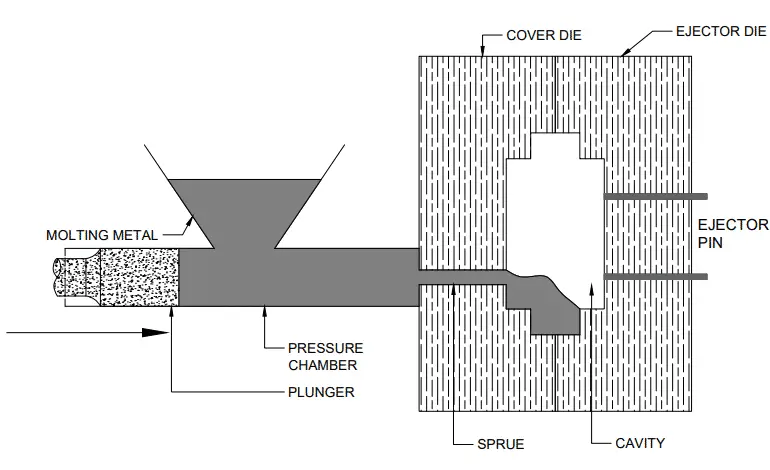

Components of Die Casting:

The Components are as follows:

- Pouring basin

- Plunger

- Pressure chamber

- Die

- Cavity

- Ejector Die and Ejector pins

Let me introduce each components,

Pouring Basin:

The molten metal is to be poured into the casting cavity via the pouring basin which is the first component of the die casting process.

Plunger:

The plunger is used to apply the pressure on the molten metal such that it can enter into the casting cavity. The plunger is used only in the Pressure Die Casting but not the Gravity Die Casting.

Pressure Chamber:

It is the region where the molten metal is pressurized into the casting cavity by means of pressure exerted by the plunger.

Die:

It has two parts. One is the Cope and the other is the Drag. Molten metal is to be poured into the casting cavity from the pouring basin via sprue and it will enter into the casting cavity.

Cavity:

Due to the presence of a cavity made by the pattern, the molten metal enters into it and acquire the shape of the cavity of the die and thus forms a component.

Ejector Die and Ejector pins:

After the solidification process, the part or product has to be removed from the casting cavity and this can be done by ejecting pins. By the usage of ejecting pins, the ejecting die can be moved from its original position so that the part produced can be taken out.

So now let me discuss the types of Die Casting.

Types of Die Casting:

There are two types of Die Casting.

- Gravity Die Casting

- Pressure Die Casting

Here's the overview of each one.

Gravity Die Casting:

- If the flow of molten metal into the mould cavity is due to the gravitational force, then it is called Gravity Die Casting.

- In this process, the molten metal is to be poured into the casting cavity via the pouring basin.

- Because of the problem of flow of the molten metal into every corner of the casting cavity due to the gravitational force, the gravity Die casting will be used for producing the simple shape of the castings only.

For example, IC engine piston made by aluminum alloys.

Note:

As this is a metal mold process, we need to remove the bond between the metal mold and the molten metal.

To avoid the formation of a bond between casting and metal mold, the Silicon powder will be sprinkled on the mold surface before pouring the molten metal into the casting.

After Solidification, the component has prepared. Now it has to removed from the casting cavity by means of Ejector pins.

Due to the ejector pins, the ejecting die will be moved from its original location such that the component produced will be moved away from the casting cavity.

Pressure Die Casting:

- If the external pressure is used for molten metal to enter into the mold cavity called Pressure Die Casting.

- Due to the external pressure, it is possible to flow the molten metal into every corner of the complex shape of a cavity. hence the complex shape of the casting can be easily produced.

For example, Carburettor body made by aluminum alloys

Pressure Die Casting is classified into two types.

- Hot Chamber Die Casting Process

- Cold Chamber Die Casting Process

Lets discuss them one by one,

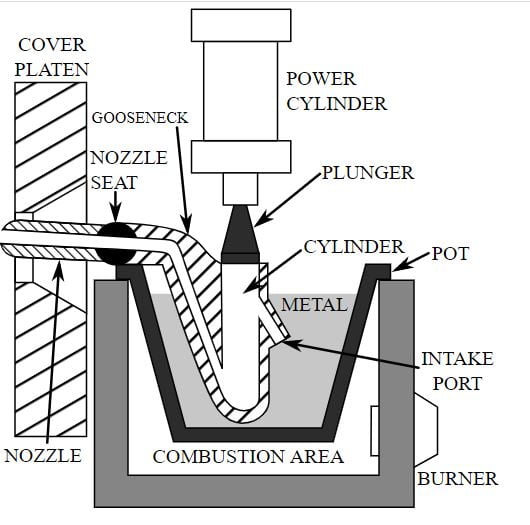

Hot Chamber Die Casting:

In this Hot Chamber Die Casting Process, the combustion area or the furnace is attached to the system itself. The metal is to be placed in the pot such that it can form into a molten metal by the application of furnace.

When the molten metal is prepared then it has to be injected into the cavity of the die so that the components can be produced.

Here the Power cylinder is either a hydraulic or Pneumatic cylinder which has piston or plunger within its body.

When the power cylinder is retracted, the plunger moves upwards into the cylinder and thereby the intake port opens which gives the entry for the molten metal to enter into the cavity via gooseneck pipe.

The gooseneck pipe is insulated such that proper solidification can be done. After it, the molten metal passes through the nozzle into the die opening and solidifies in the die.

After solidification, the component is cooled and then it is removed out from the die by moving the movable platen towards its left.

In this way, the components will be produced in the hot Chamber Die Casting Process.

Advantages of Hot Chamber Die Casting:

- Fast cycle time (approximately 15 cycles a minute) in Hot Chamber Die Casting Process.

- There is a convenience of melting the metal in the hot chamber machine itself.

- As Aluminium is not used in this process, zinc- tin and lead-based alloys were used.

Disadvantages of Hot Chamber Die Casting:

- This process is applicable to low melting point metals only.

- Aluminum cannot be used here because it picks up some of the iron while in the molten pool.

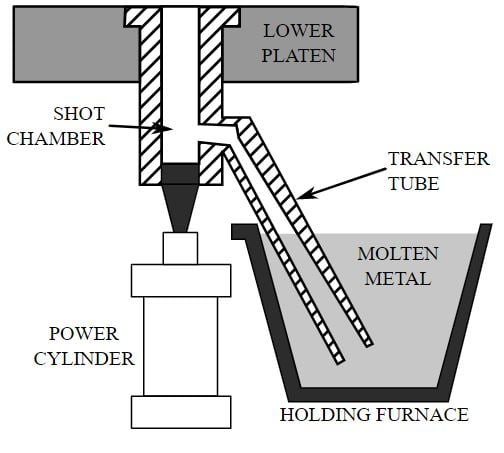

Cold Chamber Die Casting:

The only difference between these two processes was the presence or absence of the combustion chamber. As the combustion chamber was attached to the machine itself in the hot chamber die casting process.

Whereas in the Cold Chamber Die Casting Process, the molten metal is prepared away from the system and is brought up to the system by means of a laddle/holding furnace. Then the same procedure follows. i.e. the power cylinder retracts the piston such that the molten metal enters into the unheated shot chamber and then the piston/plunger is relieved so that there is an application of force on the molten metal such that it enters into the mold cavity via the nozzle.

After solidification, the component is taken out by the movement of die towards the left.

This is the explanation of the Cold Chamber Die Casting Process. Let's see the advantages and disadvantages of it.

Advantages of Cold Chamber Die Casting:

- Cold Chamber Die Casting Process can be applicable for high Melting Point metals.

Disadvantages of Cold Chamber Die Casting:

- The cycle time was very slow compared to the hot Chamber Die Casting Process.

- The cycle time was slow due to the need to transfer the molten metal from the furnace to the cold chamber machine.

- Due to this, the productivity will be less.

Applications of Die Casting Process:

The applications of Die Casting Process are as follows:

Die-casting is the largest casting technique that is used to manufacture consumer, commercial and industrial products like-

- Automobiles

- Toys

- Parts of a sink faucet

- Connector housing

- Gears etc.

- Most die castings are done from non-ferrous metals like magnesium, aluminum, etc.

What are the Advantages of Die Casting?

The advantages of Die Casting Process are as follows:

- An economical process used for a wide range of complex applications.

- A process that can be fully automated.

- Post machining can be eliminated.

- Parts have high dimensional accuracy, close tolerance, and longer service life.

- Mold can be used repeatedly because it is made up of metal.

- No external pressure is required for Gravity Die Casting Process.

What are the Disadvantages of Die Casting?

The disadvantages of Die Casting Process are as follows:

- The die cost used in the die casting process is very high.

- It is not applicable to high melting point alloys and metals.

- The larger parts cannot be cast in the die casting process.

- The lead time is large.

This is the detailed explanation of Die Casting. If you have any doubts, feel free to ask us and we will reply you as soon as possible.

FAQs:

What are the types of die?

How many types of die casting are there?

What is the difference between die casting and injection molding?

Is Die Casting expensive?

More Resources:

Sand Casting Process

Casting Process-Overview

Types of Allowances and Defects in Casting

Machine Molding and Hand Molding Operations in Casting Process

References [External Links]:

- Manufacturing – Casting methods - European Aluminium

- Metal Casting Processes-IITG