Planer Machine: Definition, Parts, Types, Working Principle, Operations, Specifications, Applications, Advantages, and Disadvantages [PDF]

Hello Readers, in today's article we will discuss the Planer Machine in brief along with its Definition, Parts, Types, Working Principle, Operations, Specifications, Applications, Advantages, and Disadvantages. So, Let's start this session with the definition of Planer Machine.

What is a Planer Machine?

A Planer is a machine tool which is just like a shaper machine designed to produce flat surfaces or planes by means of a single-point cutting tool employed for machining heavy jobs which are not possible by shaper machine. The Tool is fixed whereas the worktable (workpiece) reciprocates over the tool.

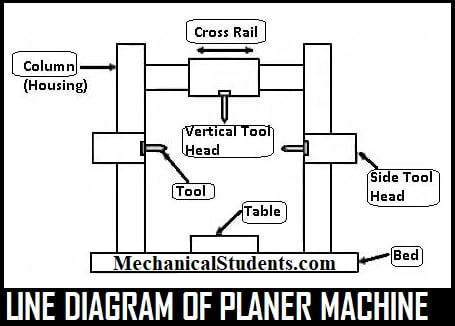

Parts with Function of Planner Machine:

The parts of Planer machine along with its functioning is as follows.

- Bed

- Worktable

- housing or column

- Cross rail

- Vertical Toolhead

- Saddle

Bed:

The bed of a planer machine is prepared by means of the casting process and as it is a large component we cannot prepare them by the machining process. So, always the larger components undergo casting only.

The bed was prepared in such a way that it has the ability to absorb the vibrations induced in the machine during various operations. Mostly Cast iron is taken as a material for the bed part of the planer.

Worktable:

The worktable is a movable part and the tool is a fixed part, therefore the worktable can be run by means of a hydraulic cylinder or by a pinion-gear mechanism.

The upper surface of the worktable has T slots for clamping the workpiece and the sides of the worktable have a groove for planer reversing dogs.

Housing or Column:

It is a hollow column that can withstand a huge amount of loads without deflection and is fastened at the bottom of the machine bed.

Two columns will rise vertically from the sides of the machine/frame on a double housing planer, as they will support the cross rail and the saddle.

Cross rail:

As discussed, it is mounted on the top of the housing. It slides up and down on the flatways which are controlled either by hand or by machine.

The weight of cross-rails was very high and that's the reason they are counterweighted by means of hydraulic cylinders or Cast iron weights.

Vertical Toolhead:

The tool head contains a tool post which holds the cutting tool to do the machining operations.

Saddle:

On the ways of cross rail, the saddle is fitted. There are two saddles located on the planer machine, one is for the right tool head and the other is for the left tool head.

How do the Planer Machine Works?

To machine wider workpieces, time taken will be very high by the usage of the Shaper Machine. Therefore, to minimize this time, more than one cutting tool will be used for removing the material simultaneously from one workpiece itself.

But for mounting more than one tool, more than one ram is required and it is nothing but more than one shaping machine will be placed parallel and is not at all preferable.

More than one cutting tool will be fixed onto a beam and allow the workpiece to reciprocate with variable speed (like optimum speed in forwarding stroke and maximum speed in return stroke). This process is called as Planing Operation or Planing Machine.

In this Planer, the workpiece will be under reciprocating motion and the tool is stationary and due to this, the material removal takes place.

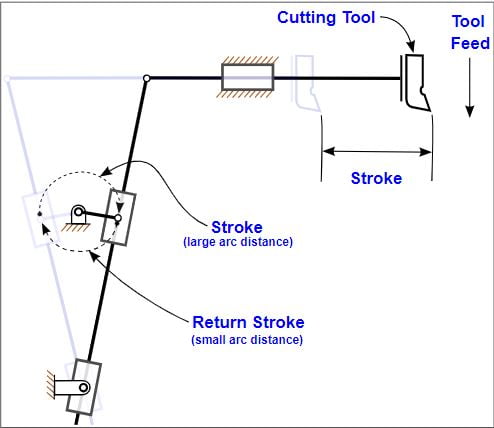

The return stroke will be the idle stroke and it is due to the mechanism called Whitworth Quick return motion mechanism.

Below is the diagram of Whitworth Quick return motion mechanism.

Types of Planer Machine:

The different types of Planer Machines are as follows.

- Standard or Double housing type planer

- Pit Type Planer

- Open side Planer

- Edge planer Machine

- Divided Table Planer

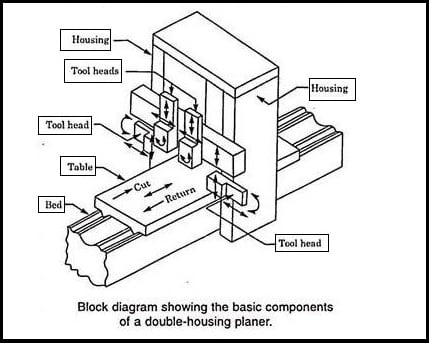

Standard or Double Housing Type Planer:

The Double housing type planer consists of two upright vertical columns which can support a cross-rail. They are employed for machining of guiding surfaces, dovetails, large beds of machines, etc.

Due to the longer planing length, a large number of components will be machined in a short period of time.

It is a old type of machine which is widely used in various workshops.

Pit Type Planer:

- It is massive in construction compared to the double housing planer. In this machine, the column which carries the cross-rail reciprocates on the horizontal rails.

- It can able to machine large surfaces that are not possible by standard type planer.

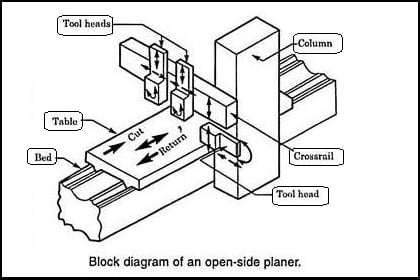

Open Side Planer:

- This is used for machining wider workpieces.

- It has only one column or housing that was present on one side of the base and a cross-rail was mounted.

- The single housing or column must be rigid because it has to carry the entire load during machining.

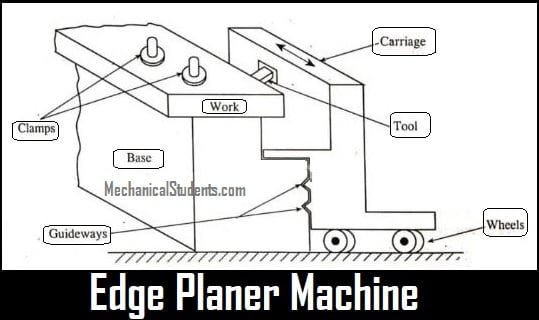

Edge Planer Machine:

- As the name indicates the Edge planer machine is used to bevel the edges of steel plates which are used in the applications of shipbuilding works and pressure vessels.

- The table which carries the workpiece remains stationary.

- There are two clamps as shown in the figure which clamps the workpiece during machining.

- The tool head moves along the guideways for quick machining of the workpiece.

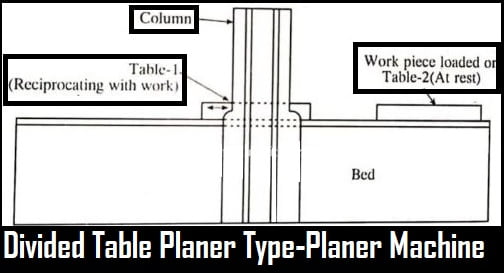

Divided Table Planer:

- A divided table planer is used for continuous mass production.

- The machine bed consists of two tables which may be reciprocated individually or together.

- While setting the work on the planer machine, it saves the idle time.

- For the preparation of large or heavy jobs, both tables are clamped together and are given the reciprocating motion under the action of a cutting tool.

Operations Performed in Planer Machine:

The various operations that are performed in the Planer Machine are as follows.

- Horizontal Flat surface planing operation

- Planing curved surfaces

- Planing Flat vertical surfaces

- Planing machining dovetails and angular surfaces

- Planing grooves and slots.

Specifications of Planer Machine:

The Planer Machine Specifications are as follows.

- The distance between the two housings of Planer.

- The maximum length of table travel during machining various operations.

- The requirement of floor space.

- Length of bed and worktable.

- Driving mechanism of a machine.

- Number of speeds and feeds available.

- Power input and net weight of the machine.

Applications of Planer Machine:

The applications of Planer machine are as follows.

- It is used in various industrial and Institutional applications.

- It is used for providing flat surfaces.

- It is used for creating keyways (cutting slots).

- Planers are used in tool and die shops.

Advantages of Planer Machine:

The advantages of Planer machine are as follows.

- Because of the multiple tools present in the shaper, the MRR will be very high compared to the shaper.

- A high surface finish can be obtained.

- Applicable for wider workpieces.

- High accuracy is maintained.

- This machine exhibits low maintenance.

Disadvantages of Planer Machine:

The disadvantages of Planer machine are as follows.

- These planers are replaced by milling machines, surface grinding machines, broaching machines, etc.

- The installation cost is high.

- The power consumption will be more as it has to remove large material from the materials compared to the shaper.

- The cost of the machine is also high.

- Skilled workers are required to operate these machines.

This is the detailed explanation on Planer Machine. If any one has any doubts, you can ask us and we will reply as soon as possible.

FAQ's:

What does a planer machine do?

What is the difference between shaper and planer machine?

What are the types of Planer Machine?

Planer machine works on the principle of?

More Resources:

Difference between Shaper and Planer Machine

Drilling machine

Milling Machine

Lathe Machine

Grinding Machine

References [External Sources]:

- Planer Machine- Scribd

- PLANING MACHINE | PLANER | ALL DETAILS | TYPES, MAJOR COMPONENTS, SPECIFICATIONS & FUNCTION [Youtube Video]