24 Lathe Machine Parts and Functions [PDF]

Lathe machine is a machine tool that removes the material from the surface of workpiece with the help of cutting tool placed either perpendicular or angular w.r.t. workpiece. It was a detailed article on Lathe Machine Parts and Functions.

You can find the detailed explanation of Lathe machine along with its Definition, Accessories, Types, Working Principle, Specifications, Operations, Applications, Advantages, and Disadvantages HERE.

Below is the explanation for various parts of lathe machine.

Lathe Machine parts:

The Parts of the lathe machine are as follows.

- Lead Screw

- Bed

- Guideways

- Prime mover

- Transmission system

- Feed Gearbox

- Headstock

- Spindle

- Chuck

- Carriage

- Tailstock

- Toolpost

- Slideways with saddle

- Thread Chasing Dial

- Split nut

- Compound rest

- Quill

- pan

- legs

- apron

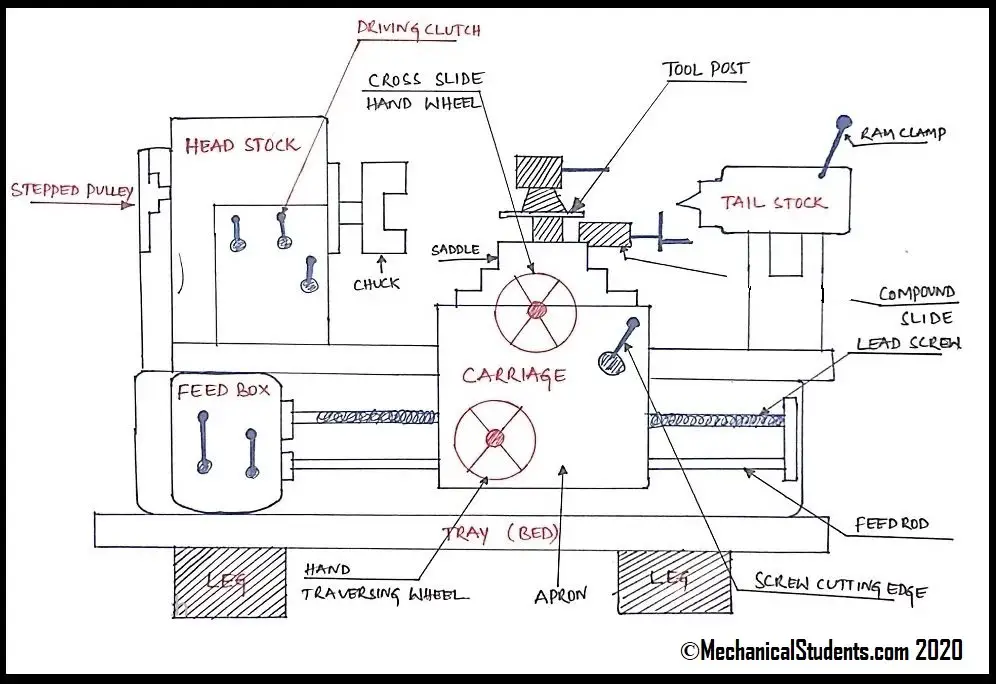

Lathe Machine Diagram:

The line diagram of lathe machine was placed below.

Lathe Machine Parts and Functions:

The detailed explanation of all the parts is as follows.

Leadscrew:

- The purpose of the leadscrew is to convert rotational movement into linear movement.

- The material of the lead screw must be selected such that it should have high wear resistance

- Due to this, the best preferable material for the manufacturing of lead screw is the brass.

- Because of the sagging problem, the maximum length of the brass lead screw will be 2 meters only.

- The type of threads used on the lead screw is square thread because it gives the highest efficiency of power transmission. For example, Buttress Thread.

Bed of Lathe machine:

- It should have high damping qualities i.e. it can absorb the vibrations induces during machining.

- It should act as a house for keeping some of the parts in a machine tool like Prime mover of a machine, gearbox, coolant tank, etc.

Material:

Grey C.I: It is used for manufacturing of bed of the machine because it has high damping qualities and rigid qualities.

Manufacturing Method:

Casting is a manufacturing method because it gives high damping qualities.

Shape:

The shape of the bed is selected such that the reduction in the rigidity of machine tool should be minimum and it should provide the maximum amount of the space.

Guideways:

- The guideways are guiding the moving parts on the surface of a machine tool.

- The material used for the manufacturing of guideways should possess High wear resistance, high damping qualities, and low ductility.

Prime Mover:

- The very first Prime mover used in machining is IC engine but because of noise pollution and result of the reciprocating parts after the invention of electrical Motors, the electrical Motors are used as a prime mover in the machine tools.

- Whenever the power supply is given to the induction motor, it always starts rotating at only one particular rpm i.e. designed rpm.

Transmission System:

- The most commonly used mechanical transmission system is the belt drive with stepped pulley because during machining operation any sudden increase In forces will cost to split the belt but no failure is taking place.

Head Stock:

Head stock is the widely used component on lathe machine. It is generally used to load the workpiece into the chuck and perform various operations.

Spindle:

- It is the hollow shaft used for transmitting power from the transmission system to the workpiece.

- It also supports the longer length of the workpiece during machining.

Chuck:

It is a work holding device used for holding the workpiece at one end.

Chuck Is classified into two types:

Three jaw chuck:

It is used to hold circular or cylindrical shape jobs.

Four jaw chuck:

It is used to hold non-circular jobs.

Feed Gear Box:

At various speeds, It is used for transmitting power from spindle to the lead screw.

Thread Chasing Dial (TCD):

To avoid multiples start of the thread with multiple cuts, Thread chasing Dial is used in thread cutting.

Split nut:

For converting rotational movement into linear movement, Split nut with the lead screw will be used.

Carriage:

The carriage is the device used for carrying a moving part in a lathe machine globally.

Slideways with Saddle:

It is used for moving the tool locally.

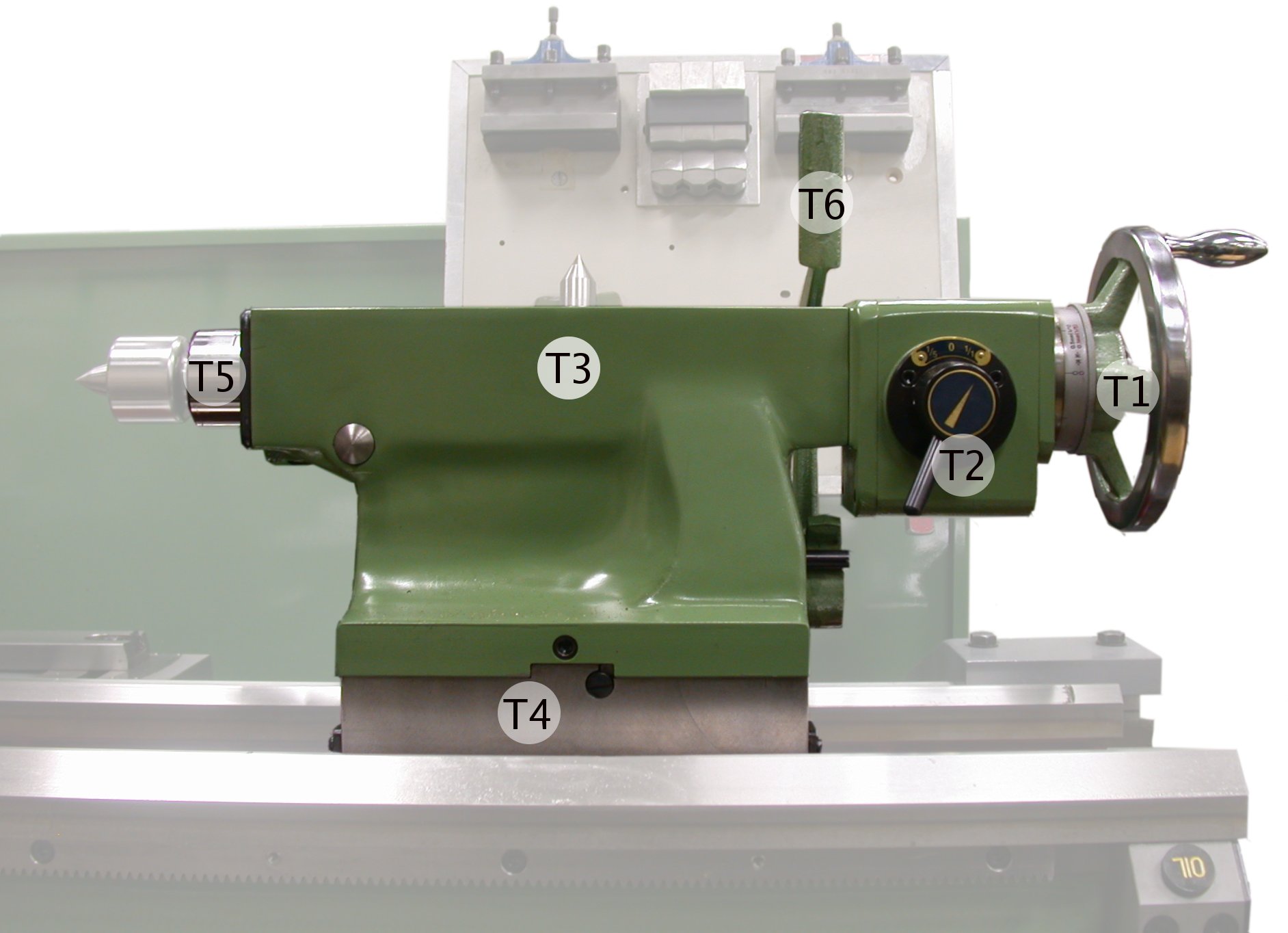

Quill:

Quill will be used for the localized movement of the Dead Centre.

Compound Rest:

To perform the taper turning operation, the compound rest is used.

Tailstock:

Tailstock and Headstock were placed opposite to each other. If the workpieces are small then there is no need of Tailstock.

It is used for supporting the large workpiece at the other end.

It can slide on the bed guideways and can be clamped in any position of lathe machine.

Tool Post:

It is the device which is used for holding the tool. The tool post can rotates w.r.t. the position of the workpiece.

- If it is a Turning operation, the tool is placed perpendicular to the workpiece.

- If it is a Taper turning operation, the tool is placed angular to the workpiece.

Cross slide:

The cross slide is moved by the feed screw, is a part of the carriage that allows the movement of a tool at right angles to the bed guideways during machining.

Apron:

An apron is situated on the carriage which consists of all controlling and moving mechanisms of carriage.

Legs of lathe:

The legs of lathe machine are made up of cast iron which has the ability to absorb the vibrations induced during machining process.

pan:

The pan is used to collect the chips during machining operation. When you are removing the material from the surface of workpiece, all the chips from the specimen will drops into the pan and will be collected by it to avoid any damage to the human body .

Functions of Lathe machine:

The main function of lathe machine is to remove the material from the surface of the workpiece to give the desired shape and size as per the dimensions.

Its function can be satisfied by performing various operations on the lathe machines including CNC machine. The various operations are as follows.

- Turning

- Facing

- Trepanning

- Drilling

- Boring

- Counterboring

- Honing

- Countersinking

- Thread Cutting

- Reaming

- Spot Facing

Specification of Lathe

The size of the lathe is specified according to:

- Length of bed

- Height of the centers.

- Swing

- Center distance

- Swing on carriage

- Maximum diameter of the bar

Lathe machine Accessories:

The Lathe Machine Accessories are as follows.

- Catch plate or Dog plate

- Steady rest

- Follower rest

- Face Plate

- Mandrel

This is the detailed explanation of Lathe machine parts and functions. If you have any doubt, you can plz comment us and we will reply you within 24 hrs.

More Resources:

Lathe machine Accessories and Attachments

CNC Machine

Lathe Machine: Definition, Parts, Accessories, Types, Working Principle, Operations, Specifications, Applications, Advantages, and Disadvantages [PDF]