[with PDF Notes] Abrasive Water Jet Machining: Definition, Construction, Working Principle, Process Parameters, Application, Advantages & Disadvantages

In the last article we had discussed the basics of the Machining process whereas, in Today's article, we will discuss the Abrasive Water Jet Machining Process along with its Definition, Construction, Working Principle, Process Parameters, Application, Advantages & Disadvantages. So, let's dive into the article.

History of Abrasive Water Jet Machining

As you know WJM is applicable for soft materials and AWJM is applicable for hard materials and this(AWJM) began in 1935 when the idea of adding an abrasive to the water stream was developed by Elmo Smith for liquid abrasive blasting.

His design was further refined by Leslie Tirrell of the Hydroblast Corporation in 1937, resulting in a nozzle design that created a mix of abrasives and high-pressure water for the purpose of wet blasting.

What is Abrasive Water Jet Machining

It is an advanced Water Jet Machining Process that includes Abrasives as a medium. To overcome the disadvantage of water jet machining, the abrasive particles will be added into the water so that the abrasive particles along with water also come out from the nozzle at a very high velocity to remove the material from the surface of a workpiece to get desired shape and size at high accuracy.

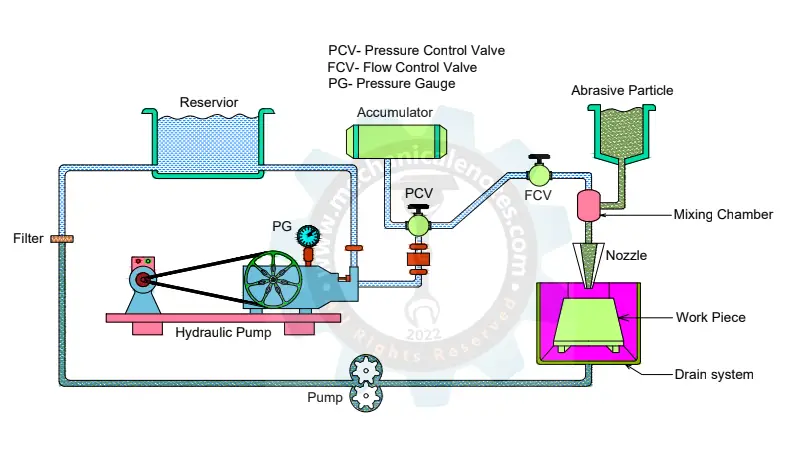

Abrasive water jet machining Diagram

The diagram of Abrasive Water Jet Machining Diagram is shown below.

Construction or the Main Parts of Abrasive Water Jet Machining

The main parts of the Abrasive Water jet Machining Process are as follows. Some of the parts of the water jet machining process are also included in the setup because the AWJM process is the advance of the WJM process.

Reservoir:

The reservoir will act as a basic part for storing water and this water is sent to all the other parts of the system to work properly.

Hydraulic Pump:

The hydraulic pump is generally used to pump the fluid from one place to another place whereas here in this unit, it acts as a mediator between the reservoir and the Intensifier. It sucks the water from the reservoir and sends it to the Intensifier.

Hydraulic Intensifier:

It is connected after the hydraulic pump and is used to increase the pressure of the water.

Accumulator:

The accumulator is used to store the water temporarily and supplies the water in the system when there is either a pressure drop or high-pressure water required in the system.

Control Valves:

- The duty of the pressure control valve is to control the pressure of water and also the direction of water.

- A flow regulator valve is used to regulate the flow of water into the system.

Flow regulator:

As the name flow regulator, it is used to regulate the flow of water which was arrived from the control valve and send that water towards the nozzle.

Abrasive Tank:

Abrasive particles play a vital role in this process. As we know that water jet machining process is used to cut soft materials whereas, in order to cut the hard materials, just water is not sufficient. In addition to water, Abrasives are also added so that the material can cut at a faster rate. The commonly used Abrasive particles are aluminum oxides, sand, garnet, glass particles, etc.

Mixing Chamber:

In the water jet machining process, only water is used as a cutting medium whereas, in the Abrasive Water Jet Machining process, 70% water and 30% Abrasive particles are used and they are mixed in the mixing chamber.

Nozzle:

The duty of the nozzle is to convert high-pressure water into kinetic energy(K.E) and this K.E. is increased due to the decrease in the nozzle area. This high K.E. water along with the abrasive particles is impinged onto the surface of the workpiece to get the desired shape and size at a faster rate.

Drain system:

The main duty of the drain is to collect the water coming away from the work region and is supplied back to the reservoir via the pump and the filter.

Working of Abrasive Water Jet Machining Process:

The water from the reservoir is to be passed to all the parts of the system starting from the reservoir to the drain system. Firstly, the water is passed through the hydraulic intensifier where the pressure of the water increases and is to be sent to the accumulator for storing the water on a temporary basis.

The control valves are placed in the system to control the pressure of water and the directional flow of water. Next, the abrasive particles along with water in a percentage of 30 & 70 are mixed in the mixing chamber.

When these high-velocity Abrasive particles are impinging onto the hard workpieces, it is possible to produce plastic deformation fracturing in the hard work materials.

As the percentage of abrasives is increasing, the material removal also increases but the flow characteristics of the liquid mixture are coming down.

Therefore the optimum percentage of abrasives will be about 40 to 60%.

It is mainly developed for cutting granite and marble of complex shapes.

Abrasive Water Jet Machining Process Parameters

The parameters of the Abrasive Water Jet Machining process are as follows.

- Water flow rate

- Water Pressure

- Abrasive Flow rate

- Abrasive particle size

- Abrasive materials

- Nozzle diameter

- Traverse rate

- Stand-off distance

- Depth of cut

- Material properties.

Abrasive Particle size:

The most common usage of abrasive particles in the AWJM process is in the range of 100 to 150 grit.

Abrasive Materials:

The most used abrasive materials are Garnet(which is 30% more efficient than sand), silicon carbide, and silica.

Traverse rate:

The depth of cut decreases when the traverse rate is increased. The Traverse speed maintained is 100 mm/min to 5 m/min.

Stand-off distance:

If the stand-off distance is increased, the depth of the cut is decreased. The stand-off distance maintained is 1-2mm.

Depth of cut:

The depth of cut maintained is in the range of 1 mm-250 mm.

These are the various parameters of the Abrasive Water Jet Machining process. Let's discuss its applications, advantages, and disadvantages in a brief.

It's Applications

The applications of Abrasive Water Jet Machining are as follows.

- It is highly used in the automotive, aerospace, and electronics industries.

- In aerospace industries, parts such as engine components (aluminum, titanium, and heat resistant alloys), aluminum body parts, titanium bodies for military aircraft, etc. are made using abrasive water jet machining process.

Advantages

The advantages of Abrasive Water Jet Machining are as follows.

In most cases, no secondary finishing is required

- No heat-affected zone

- No cutter induced distortion

- Eliminates thermal distortion

- Low cutting forces on workpieces

- Localises structural changes

- No slag or cutting dross

- Limited tooling requirements

- Typical finish 125-250 microns

Disadvantages

The disadvantages of Abrasive Water Jet Machining are as follows.

- high capital cost and high noise levels during machining.

- It cannot cut the materials that degrade quickly with moisture.

- Surface finish loses at higher cut speeds.

This is a detailed explanation of the Abrasive Water Jet Machining Process. If you have any doubts, you can ask us and we will reply to you within 24 hrs.

More Resources:

Non-Traditional Machining Process

Electrical discharge machining Process

Electrochemical Machining Process

Electron beam machining Process

Electrochemical Grinding Process.

Electric Discharge Machining Process