Water Jet Machining: Working, Advantages, Disadvantages & More [with PDF]

In the previous article, we had discussed Electron Beam Machining, Ultrasonic Machining, Electrical Discharge Machining, and Electrochemical machining whereas, in today's article, we will learn various concepts of Water Jet Machining along with its Definition, Construction, Working Principle, Types, Applications, Advantages & Disadvantages in a detailed way.

History of Water Jet Machining

If you look into the history, a Paper Patent Company used relatively low-pressure water for cutting soft materials whereas now, in the current scenario, it is used to cut various hard materials ranging from plastics to metals.

What is Water Jet Machining?

Water Jet Machining or Water Jet Cutting is a type of cutting tool widely used in many industrial applications by the usage of an extremely high-pressure jet of water onto the workpiece to get the desired shape and size.

Few Types of Water Jet Machining and How They Works

There are two types of water jet machining processes and are as follows.

- Pure Water or Water Jet Machining Process

- Abrasive Water Jet Machining Process

Water Jet Machining Process:

Water Jet Machining is applicable for soft materials. It acts as a cutting tool by the usage of an extremely high-pressure jet of water onto the workpiece to get the desired shape and size.

In this, no tool is used and the only nozzle is used to withstand higher pressures. Water is used as a medium and the wear ratio is infinity.

To overcome the limitations, the Abrasive water jet machining process came into existence.

Abrasive Water Jet Machining Process:

To overcome the disadvantage of water jet machining, the abrasive particles will be added into the water so that the abrasive particles along with water also come out from the nozzle at a very high velocity to remove the material from the surface of a workpiece to get desired shape and size at high accuracy to get faster production in a small interval of time.

A detailed explanation of the Water Jet Machining Process was elaborated below.

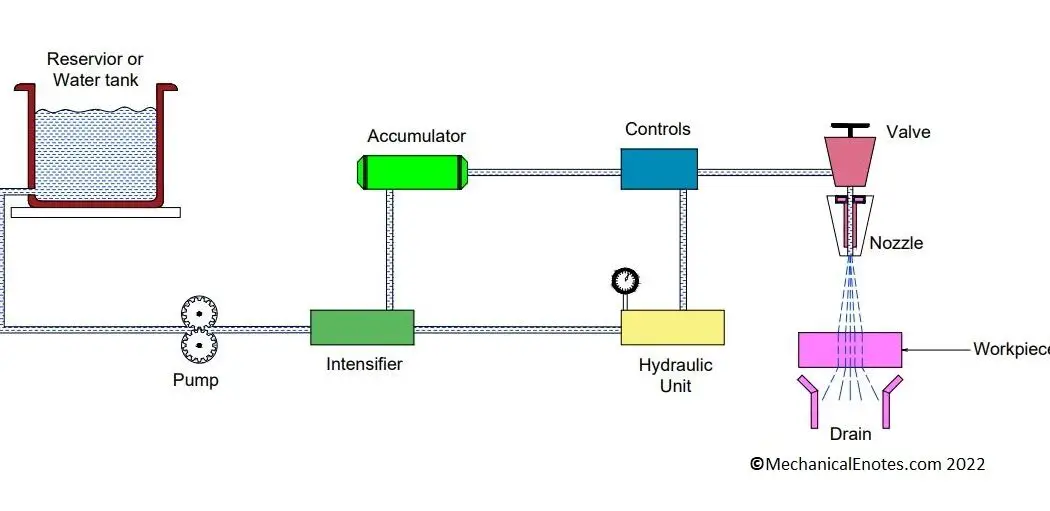

Water Jet Machining Diagram:

The diagram of the Water jet machining process is shown below.

Construction or the Main Parts of Water Jet Machining

The main parts of the Water jet Machining Process are as follows

Reservoir:

The reservoir acts as the basic unit in the setup which is used for storing water.

Pump:

The pump acts as a mediator between the reservoir and the Intensifier. The pump sucks the water from the reservoir and sends it to the Intensifier. The pump creates pressure in the water ranging from 1500 to 4000 bars.

Hydraulic Intensifier:

It is connected after the hydraulic pump and is used to increase the pressure of the water from 4 bar to the pressure ranging from 3000-4000 bar.

Accumulator:

The accumulator is connected after the hydraulic intensifier and it is used to store the water temporarily. Accumulator supplies the water in the system when there is a need for either a drop of pressure or high-pressure water required in the system.

Control Valve:

The duty of the control valve is to control the pressure of water and also the quantity of water to be passed into the system.

Flow regulator:

As the name flow regulator, it is used to regulate the flow of water which was arrived from the control valve and send that water towards the nozzle.

Nozzle:

The duty of the nozzle is to convert high-pressure water into kinetic energy(K.E) and this K.E. is increased due to the decrease in the nozzle area. This high K.E. water is impinged onto the surface of the workpiece to get the desired shape and size.

Drain:

The main duty of the drain is to collect the water coming away from the work region and is purified again to act as the main agent into the system i.e. the purified water is again sent to the reservoir.

These are the parts of the Water Jet Machining Process. Let's see the Working of WJM...

Working of Water Jet Machining Process:

The working of WJM is as follows.

- When very high-pressure water is passing through the convergent nozzle the pressure energy is converted into velocity energy or kinetic energy.

- Therefore the water is coming out from the nozzle at a very high velocity which is obtained to be 200 to 400 m per second.

- When this high-velocity water Jet is impinging onto the workpiece, the continuous impact load is acting onto it.

- Therefore very soft materials will experience plastic deformation and fracturing.

- From the above, the mechanism of material removal is due to plastic deformation and fracturing and also called an Etching process.

- In this, the Material Removal Rate(MRR) is directly proportional to the velocity of the water jet and this velocity depends on the distance between the nozzle tip and workpiece.

- In this, no tool is used and the only nozzle is used and to withstand higher pressures.

- The nozzle is made by using Tungsten Carbide.

From this,

- Medium: Water

- Wear Ratio: Infinity.

It's Applications

The applications of Water Jet Machining (WJM) are as follows.

- It is used for machining or cutting reinforced plastic.

- Use to cut stone which can reduce the dust in the environment.

- It is used to cut hard metal like titanium, stainless steel, etc.

- It is used in aerospace industries.

- Used for machining PCB.

Advantages

The advantages of Water Jet machining are as follows.

- Very soft materials like rubber can be easily machined

- No electrical conductivity of workpiece is required

- No thermal effects on the workpiece are required.

Disadvantages

The disadvantages of Water Jet machining are as follows.

- Pressurizing the water to very high pressure is difficult.

- This method can't be used for the machining of hard materials.

- Developed for cutting of very soft materials like rubber.

This is a detailed explanation of the Water Jet Machining process. However, you can see the advance of WJM i.e. Abrasive Water Jet Machining process in the next article.

If you have any doubts, you can feel free to ask and we will reply to you as soon as possible.

More Resources:

Media Credits:

Image: By Saubhik Roy- Design Team MechanicalEnotes

Video: By: Fireball Tool