Quick Return Mechanism of Shaper Machine [With PDF]

This article is all about Quick Return Mechanism of Shaper Machine.

In this write up you'll learn:

- Definition if Quick Return Mechanism.

- How Quick Return Mechanism Works in Shaper Machine?

So without further ado, let's get started.

What is Quick return mechanism?

A quick return mechanism is an apparatus that consists of a system of links with 3 turning pairs and a sliding pair that can convert rotary motion into reciprocating motion. The time taken for travel in return stroke is less than in forward stroke.

Quick Return Mechanism of Shaper Machine:

A quick return mechanism is also known as Crank and slotted lever quick return motion mechanism.

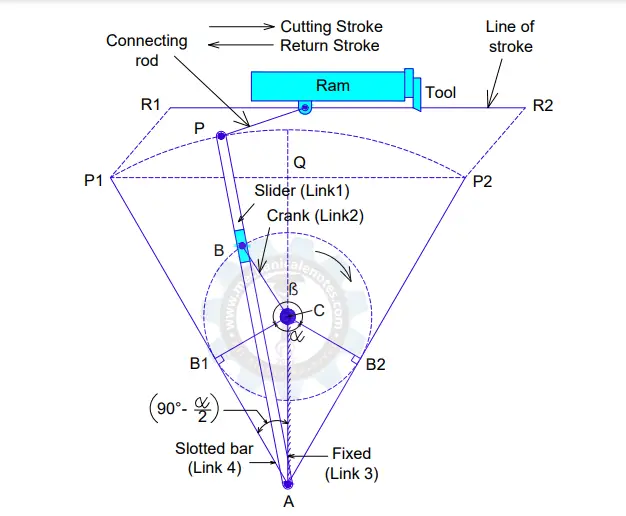

It consists of 3 turning pairs and one sliding pair as shown below.

Links used in this mechanism:

- Slider

- Crank

- Frame

- Slotted Lever

Pairs:

- Frame & Slotted lever – turning pair

- Frame & Crank – turning pair

- Crank & Slider – turning pair

- Slider & Slotted lever - Sliding pair

In this mechanism, the link AC is fixed and form a turning pair with a crank and slotted lever as shown in the figure. The driving crank CB revolves with respect to the fixed center C with a uniform angular speed.

A sliding block B is attached at point B and slides on the slotted lever AP. A connecting rod is pivoted at the end of AP and the Ram.

The ram carries a single-point cutting tool that moves forward and backward on the line of stroke R1R2 and the AC is perpendicular to the line of stroke.

As shown in the figure, AP1 and AP2 are tangential to the circle. When the crank rotates from CB1 to CB2 through an angle β in a clockwise direction indicates that the tool is reciprocating in the forward direction for the Cutting stroke.

Similarly, when the crank rotates from CB2 to CB1 through an angle α in the Anti-clockwise direction, it indicates that the tool is under a reciprocating motion for the return stroke or the IDLE stroke.

Note:

As you can observe that the travel of crank in return stroke will be less compared to the forward stroke. Therefore the return stroke is faster than the cutting stroke. i.e. the forward stroke is making an angle β which is more than the return stroke α.

In the case of Shaper Machine, the Workpiece is fixed in the machine vice and the Tool is under the Reciprocating motion of the ram and the material removal takes place from the surface of the workpiece in the form of layers.

Now I'd Like to Communicate with You:

There you have: quick return mechanism of shaper machine.

I hope you enjoyed this article, and learn the principle of quick return mechanism.

Now I've some specific questions for you:

Did this article help you?

Do you have any doubts regarding this?

You can let me know by leaving a quick comment below, I'll reply to you within 24 hours.

In the meantime, you can see my other articles too.

More Resources:

Planer Machine

Shaper Machine

Shaper VS Planer Machines