Glass Cutting Process: Properties, Tools, Applications, Advantages, & Disadvantages [PDF]

Glass is a non-crystalline amorphous solid that is often transparent and has widespread practical, technological, and decorative usages in the industry. In this article, we will discuss on Glass Cutting Process along with its Introduction, Properties, Types, Advantages, Disadvantages, and Applications.

Examples of glass include window panes, optoelectronics, tableware, etc. But, do you know that Glass is made up of liquid sand?

How Glass Made?

- The glass is made by heating ordinary sand (which is mostly made up of silicon dioxide) until it melts and turns into a liquid. Sand melts at a high temperature of 1700°C (3090°F).

- In a glass plant, sand is mixed with waste glass, limestone (calcium carbonate), and soda ash (sodium carbonate) heated in a furnace.

- The soda reduces the sand's melting point, which helps to save energy and time during the manufacturing process, but it has a drawback that it produces a kind of glass that would dissolve in water and that (dissolving in water) can be eliminated by adding Limestone to the mixture.

- The end product is called soda-lime-silica glass and it is the ordinary glass that we are using in our domestic applications.

Formation of Glass:

Understand the formation of glass in an easiest way:

(Waste Recycled Glass +Sand + Calcium Carbonate + Sodium Carbonate) --> Heating -->Annealing-->Finishing.

I think you had understood, how the glass is really made? But do you know what are the various properties of glass...

Properties of Glass:

These are some of the properties of Glass:

- It is amorphous.

- These are affected by alkalis.

- It is very brittle.

- Possesses high compressive strength and since it doesn't have any crystalline structure.

- It Softens on heating

- Light in weight because it has a homogeneous internal structure similar to liquids.

- It can absorb, transmit, and reflect light.

- It is a good electrical insulator.

- Glass is not affected by air, water, etc. But, it is soluble in HF which converts into SiF4.

After knowing the properties of glass, we can come to know, how to cut it...So let's see the procedure of cutting glass with the help of Glass cutting tools.

The Procedure of Glass Cutting Process:

To cut the glass, we use the glass cutter tool which has the principle of Scribe and Break.

Glass Cutting Tools:

The glass cutting tools which are used to cut the glass are as follows.

- Wheel Cutting or Glass Cutter

- CO2 Laser Cutting

The explanation to the glass cutting tools are presented below.

Wheel Cutting or Glass Cutter:

In the Middle Ages, glass was cut with a heated and sharply pointed rod of iron. The Diamond can also act as cutting material for glass. Nowadays we used different methods to cut the glass.

A Glass Cutting Tool consists of 3 Parts

1. Wheel:

It is a small wheel attached to the glass cutter whose role is to cut the glass plate w.r.t. the dimensions easily. The glass after cut by cutting wheel has sharp corners. So, care must be taken during operation.

A glass cutter more commonly uses a small cutting wheel made of hardened steel or Tungsten Carbide of 4–6 mm in diameter with a V-shaped profile called a "hone angle" is used.

The greater the hone angle of the wheel, the sharper the angle of the V, and the thicker the piece of glass it is designed to cut. The honing angle on most hand-held glass cutters is 120°.

2. Holders or Grips:

After marking the glass with the cutting wheel, the glass cutter has to be inserted into the corners of glass and tilt it so that it can break w.r.t the mark made.

3. Ball:

The ball attached at the end of the glass cutter is used for tapping the glass piece if any irregularities are present at the corners of glass after the cut.

This is the explanation of the "wheel cutting" tool in a detailed way which is one of the Glass Cutting tools.

So, let's see the detailed explanation of CO2 Laser cutting process in a detailed way.

CO2 Laser Cutting Process:

Cutting the glass with conventional methods (Wheel Cutting) as stated above uses the principle of Scribe and Break.

In the sense, you need to scribe on the surface of the glass w.r.t. the dimensions and Break that particular part.

By doing so, relatively low scribing quality results in the formation of micro-cracks and that leads to the damage of glass.

In addition to that, various time-consuming processes like grinding, masking, and etching are necessary to remove the damage that had been introduced by mechanical processes (Conventional Methods).

Using a laser for the glass cutting process avoids all the limitations stated above.

By this laser cutting, the Straight, angled, curved, and chamfered contours are possible.

The laser beam is used to cut different materials like metal, wood, rubber, glass, plastics, etc.

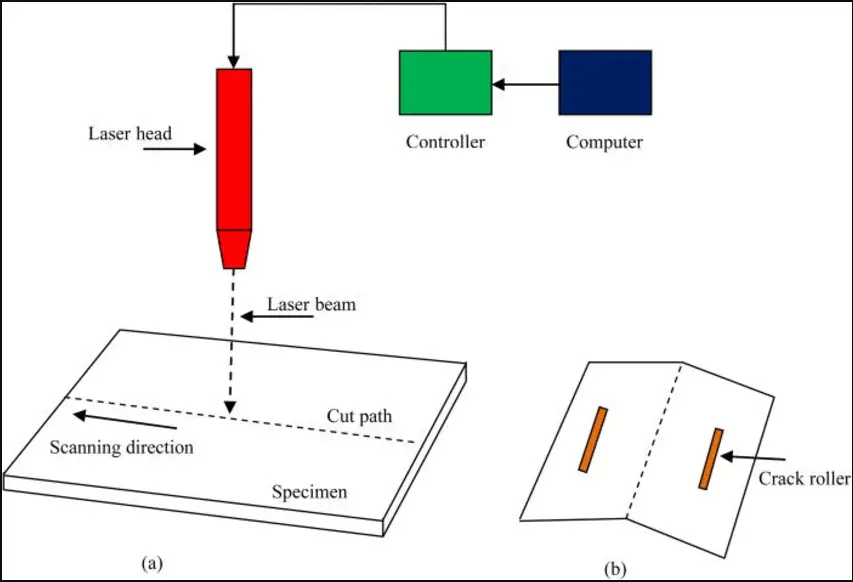

Laser cutting machines are equipped with computer-controlled programming that helps to do the work more efficiently and easily. By this, a high degree of accuracy is maintained.

This is the detailed explanation of two types of cutting tools used in Glass Cutting Process.

Let's see the advantages, disadvantages of the Glass Cutting Process along with its applications.

Applications of Glass Cutting Process:

The applications of Glass Cutting Process are as follows.

- Small scale industries use wheel cutter to cut the glass for their regular usage. Apart from that, it is also used in labs in colleges for doing experiments on the cutting processes.

- As Large Scale industries require faster production and accuracy, Laser cutting is used to avoid the breaking of the glass at frequent intervals.

- Glass is used as decorative items or window panes etc.

Advantages of Laser Cutting Process:

The advantages of Laser Cutting Process are as follows.

- It can easily cut simple and complex structures.

- Human intervention is for Inspection and repairs and thereby it is a time-consuming process.

- Performs various Operations at a time.

Disadvantages of Laser Cutting Process:

The disadvantages of Laser Cutting Process are as follows.

- Metals like copper and aluminum can't be cut using this technology.

- Laser cutting of plastic components can be more expensive compared to glass because when the plastic is exposed to heat, it emits the gas. For this reason, the laser cutting service provider should have a well-ventilated room, which is quite expensive.

- No human intervention is required in this process and thereby it affects employability.

This is a detailed explanation of the Glass Cutting Process along with its Introduction, Properties, Types, Advantages, Disadvantages, and Applications.

Faqs:

How does a glass cutter work?

How thick of glass can you cut with a glass cutter?

What is the best tool to cut glass?

More Resources:

Injection Moulding Process

Compression Moulding Process

Blow Moulding Process

References [External Links]:

- Laser Glass Cutting Techniques

- Journal of Laser Applications