Casting: Definition, Types, Steps involved in casting, Advantages, Disadvantages, Importance [PDF]

Definition of Casting:

Casting is a process in which the liquid molten metal is poured into the casting cavity whose shape is same as that of the shape of the casting to be produced, allowing to solidify and after solidification, the casting will be taken out by breaking the mould called as Casting Process.

Types of Casting Processes:

There are various types of Casting Processes but out of which, I will be explaining only four types of casting processes in detail. They are

- Sand Casting Process

- Die Casting Process

- Shell mold Casting Process

- Investment Casting Process

The explanation for the types of Casting processes are as follows.

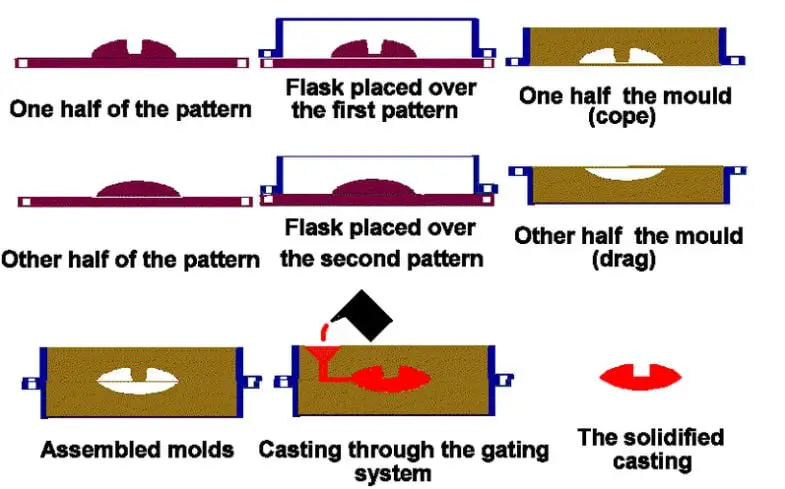

1.Sand Casting Process:

Sand Casting is a process in which the liquid molten metal is poured into the casting cavity whose shape is the same as that of the shape of the casting to be produced, allowed to solidify and after solidification, the casting part will be taken out by breaking the mold called as Sand Casting Process.

The parts of the Sand casting process are Cope and drag, Sprue, Pouring Basin, Runner, Ingate, Casting Cavity, Riser, Parting Line, Chaplets, etc.

With the help of sand casting process, cylinder blocks, machine tool beds, pistons, etc. can be produced.

2.Die Casting Process:

Die Casting is a metal casting process which is characterized by forcing the molten metal into a mold cavity under high pressure or under gravity.

In Sand Casting Process, the Mould is made up of Sand whereas, in Die Casting Process, the mold is made up of Metal.

Types of Die Casting Process:

There are two types of Die Casting process.

- Gravity Die Casting

- Pressure Die Casting

Gravity Die Casting:

If the flow of molten metal into the mold cavity is due to the gravitational force, then it is called Gravity Die Casting.

Pressure Die Casting:

If the flow of molten metal into the mold cavity is due to the external pressure, then it is called Gravity Die Casting.

3.Shell Mold Casting Process:

If the mold is made like a shell called shell mold casting. Shell means the thin mold or Hollow mold.

The material used for mold is a Phenolic resin (Thermosetting Plastic) has the viscosity of (Dynamic Viscosity equal to 1500 to 2000 Centipoise). You can dip the pattern into phenolic resin for 1 to 2 minutes and take the pattern out.

This method is used for producing the symmetrical and circular shape of castings only.

4.Investment Casting Process:

In the Investment Casting Process, the wax is used as a Pattern Material whereas Cement Concrete is used as a Mould Material.

Because of Cement concrete mold, the same mold can be used for producing a few numbers of castings. Therefore, it is also called a Semi-Permanent Mould Casting Process.

Steps involved in the Casting Process:

There are 5 steps involved in Casting process and they are as follows.

- Pattern making

- Mold and Core making

- Pouring and Solidification

- Fetling

- Inspection

1.Pattern Making:

The pattern is the replica of the casting to be produced. Replica means the shape of the pattern is same as the shape of the casting to be produced.

Pattern Size = Casting size (+/-) allowances.

Types of Allowances:

There are five types of allowances in the casting process.

- Shrinkage allowance

- Machining allowance

- Draft allowance

- Shake allowance

- Distortion allowance

Read: Types of allowance and defects in casting process

Properties possessed by the Pattern:

- No moisture absorption by the pattern material would take place.

- Surface finish produced on the pattern material must be good or excellent.

- The material should be of low density.

- Easiness in fabrication.

- It should be cheaper (Pattern Cost).

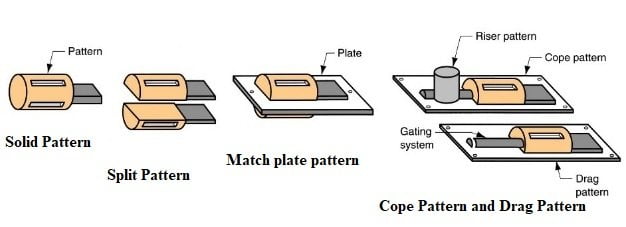

Types of Pattern in Casting:

There are 4 types of pattern in casting process and are as follows.

- Solid pattern

- Split pattern

- Match plate pattern

- Cope Pattern and Drag Pattern

Types of Pattern Materials:

The different types of pattern materials used in the casting process are as follows.

Wood Pattern:

Except for moisture absorption, the wood is possessing all other properties which are required as pattern material, and out of all the different woods, the wood which is absorbing less moisture will be used as pattern material.

Example: Teak wood, Mohagaoni, etc.

Metal Pattern:

In the case of metal patterns, the density is high and it is difficult to manufacture the metal patterns.

Ex: Aluminium, white metal, Titanium has low density, but they are very costly.

Aluminium = 2.7 gm/cc

White metal = 3.2 gm/cc

Titanium = 4.3 gm/cc

When wooden parts are used for producing metal patterns, the double shrinkage allowance must be provided on the wooden pattern.

Plastic Pattern:

They are processing all the properties which are required for pattern material.hence in today's manufacturing industry, plastics are the most commonly used pattern materials.

Ex: Epoxy resin, PVC, Nylon, Cellulose, Polystyrene, etc.

Polystyrene: It is used for producing very large castings where the removal of the pattern is not possible.

Ex: Producing bed of Machine.

Wax Pattern:

It will be selected as pattern material for producing the complex shape of the pattern, to produce the complex shape of the casting i.e. because of the highest softness of the wax material, it is possible to produce the Complex shape of the pattern easily.

2.Mold and Core making:

After creating a pattern with any of the material mentioned above, we need to create sand mould.

For creating a sand mould, the properties of green sand has to be known.

Let's understand what is mold, what is a molding, and what are the different molding materials in detail...

What is mould or mold?

- It is described as a void or cavity created in a compact sand mass with the help of a pattern which (mold), when filled with molten metal produces a casting.

- The mold is made by using the molding sand consists of basic elements such as

- Silica Sand Particles: They are used for producing the required strength of the molding sand. (75-80%) of sand is filled with Silica sand Particles.

- Clay: It is used for producing the bond between the sand particles. (15-20%) of clay is filled in molding sand.

- Water or Sodium Silicate: It is used for initiating the bond formation between the sand particles(6-8%).

Silica Sand + Clay + Water = Green Sand.

Silica Sand + Clay + Sodium Silicate = Dry Sand.

Green Sand or Dry Sand with 50% Clay is called as Loam Sand.

What is a molding?

The process of making a cavity or mold in the compact sand is called as Moulding.

What are molding materials?

- A material which possesses high refractoriness can be used for mold making. Thus, the mold making material can be metallic or non-metallic(sand).

- For Metallic Moulds, the common materials are Cast iron, mild steel, and alloy steels.

- For Non-Metallic Moulds: Materials used are molding sand, Plaster of Paris, silicon carbide, graphite, and ceramics.

Note:

Out of all materials, the molding sand is the most commonly utilized non-metallic molding material because of its certain inherent properties namely refractoriness, high permeability, and workability along with good strength. Moreover, it is also highly cheap and it is easily available.

Core making:

In order to create hollow components in casting process, core is to be placed in the casting cavity and when the molten metal surrounds the core, a hollow component is produced.

3.Pouring and Solidification:

After the creation of pattern, core as well as mould, the next step is to pour the molten metal into the sand molding.

When the molten metal is poured, it will not move to each and every corner. Therefore, chills are provided at the corners to do the solidification fastly.

4.Fetling:

Fetling is nothing but, breaking of the mould after production of a component so as to take it out from the sand mould.

5.Inspection:

After production of component, it is inspected under the guidance of quality engineers and further it is sent to the machining shop where the surface finish of the component is to be done.

These are the five steps involved in the casting process.

Advantages of Casting:

The Advantages of Casting Process are as follows.

- High complexity shapes: Casting processes can create any complex structures economically.

- Short lead time: Short lead time compared to others and hence, ideal for short production runs.

- Low-cost tooling: Tooling and equipment costs are low compared to some other metal manufacturing processes.

- Design flexibility: The size of an object doesn’t matter for casting.

- Wider material choice: all types of engineering alloys can be cast.

Disadvantages of Casting:

The disadvantages of Casting Process are as follows.

- Dimensional accuracy: Because of shrinkage in the casting, the dimensional accuracy might be at risk. So, the designers must take care of providing the allowance to the product(Pattern) before pouring the molten metal.

- Low strength: Due to high porosity compared to a machined part.

- Post-processing: It requires Secondary machining operations in order to improve the surface finish.

- Lower Melting Point: Generally limited to metals of the lower melting point.

- Not suitable for low-volume production.

Importance of Casting Process:

- This process is widely used to manufacture complex parts.

- All major parts like milling machine bed, the bed of lathe machine, IC engine components, etc. are made by this casting process.

- It produces the best quality sand casting products at the lowest possible cost compared to the machining process.

- High Production rate.

References:

- Metal casting processes

- MIT Casting Procees

- Chapter 11: Fundamentals of Casting