Lathe Machine Accessories and Attachments [With PDF]

Hello Readers, today in this paper we will discuss Lathe Machine Accessories and Attachments, after complete reading this article you will understand the devices which are used in lathe machines, and be able to differentiate between Lathe Accessories and Attachments. So let's get started.

Lathe Machine Accessories:

The Lathe Machine Accessories are those which are used for holding and supporting the work material or for holding the cutting tool.

Here are a couple of important Accessories which are used in Lathe machines:

- Face Plate

- Catch plate or Dog plate

- Mandrel

- Steady rest

- Follower rest

- Chuck

Let's discuss it one by one.

Face Plate:

It is used for holding the irregular shape of the workpieces.

Catch Plate or Dog Plate:

Catch plate is used for positive power transmission from the live Centre to the workpiece.

Mandrel:

A mandrel is used during the machining of thin hollow cylindrical jobs without any bending of the component.

Steady Rest:

It is used for supporting long cylindrical jobs during machining to avoid the bending or deflection of the workpiece.

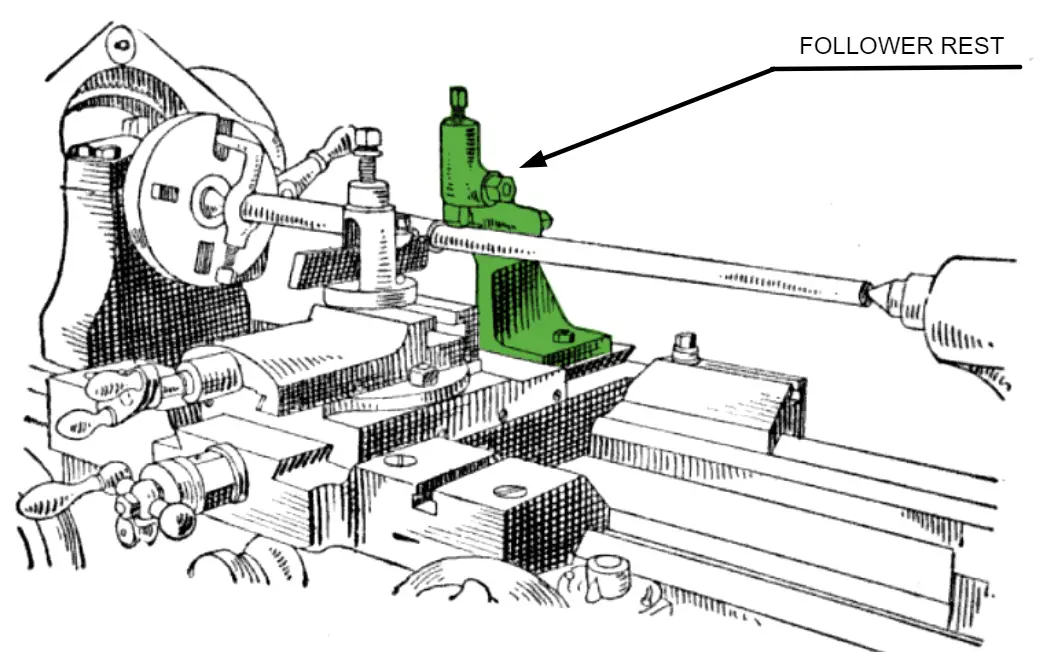

Follower Rest:

To avoid the bending of the workpiece, due to the cutting forces acting by the tool, exactly opposite to the tool, support is provided and it is moving along with the tool called as follower rest.

Chuck:

Chuck is used to holding the workpiece when the machining operation is taking place.

The workpiece is fixed in the chuck and is under rotary motion whereas the tool is stationary.

By changing the angle of the tool, various lathe operations can be performed like turning, facing, taper turning, step turning, etc.

Mostly two types of chucks are used. One is Three Jaw Chuck and the other is Four jaw chuck.

The Three Jaw chuck is used to hold circular components whereas the Four jaw chuck is used to hold Rectangular or Square cross-section components.

Attachments Used in Lathe Machine:

Sometimes it's quite hard to use conventional machining for various types of operation, as these machines are built for a particular operation. So to overcome this we need to have some devices which extend the limit of operation in Conventional Machines like Lathe. Attachments are not a mandatory element of a Machine, it is only used for performing specific operations like Milling in Lathe, Taper turning, Grinding, etc.

In a Lathe Machine, these are some attachments that are widely used:

- Milling attachment for lathe

- Taper turning attachment for lathe

- Grinding attachment for lathe

- Gear cutting attachment for lathe

- Spherical attachment for lathe

Let's discuss this one by one.

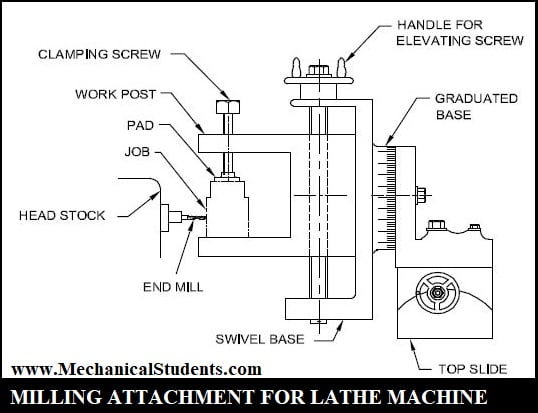

Milling Attachment for Lathe:

These attachments are used to make helical grooves, flat surfaces, deep screw threads, worms, helical grooves, keyway cutting, Tee Slot cutting, thread milling, etc.

The milling attachment is generally fixed in the place of the Compound rest of the lathe machine.

It generally consists of a milling head and a spindle to hold the milling cutter which is mounted on the milling attachment. It consists of a motor that can act as a driving mechanism in the milling machine.

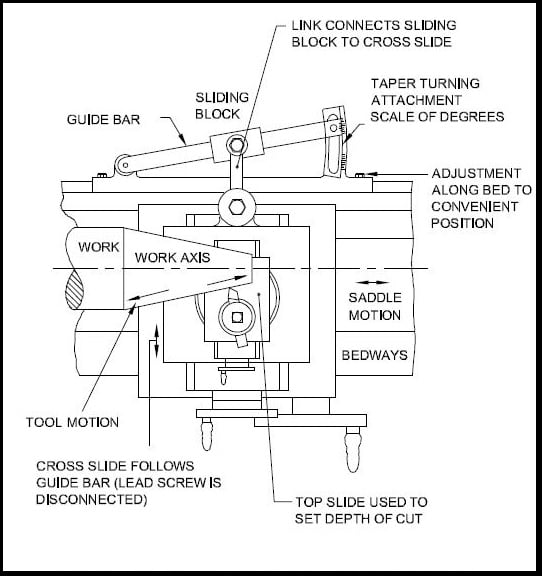

Taper Turning Attachment for Lathe:

The tapered bar of the lathe machine can be set with different angles to the spindle axis. A link connects the sliding block to the cross slide where the sliding block is carried by the guide bar during taper turning operation.

Through 90 degrees, the top slide is swung to lie at right angles w.r.t. the work so that the depth of cut can be applied.

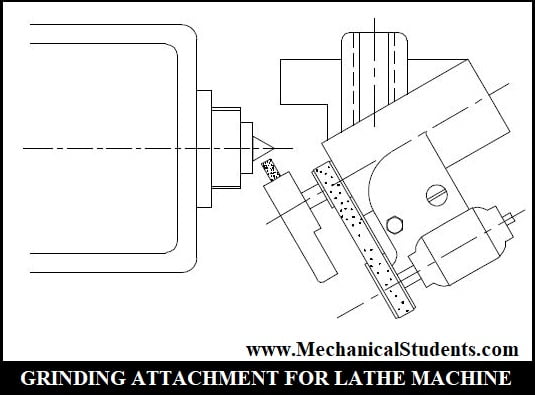

Grinding Attachment for Lathe:

The grinding attachment for the lathe machine is similar to the Milling attachment. With the help of this attachment, the lathe can be used for the sharpening of milling cutters and reamers.

The bed ways of the lathe are covered properly with any cloth to protect from dust. The water or oil is placed in a small pan such that the grit falls in it without laying on the bed ways.

For external grinding, a powerful grinder is used which might be at least 100mm in diameter and should mount on the compound rest of the lathe.

The grinding attachment is used for internal and external cylindrical grinding, splines, finishing grooves, etc.

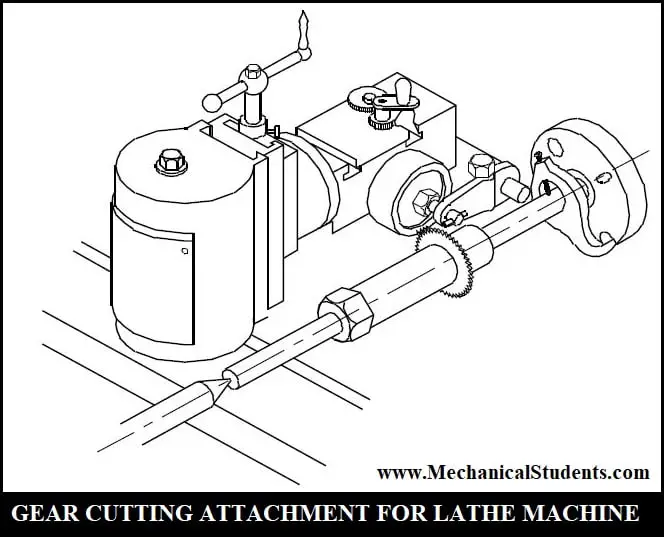

Gear Cutting attachment for Lathe:

This gear cutting attachment will cut the bevel gear and spur gear. The external keyway cutting, linear indexing, slotting and all regular works can be done by the use of this Gear cutting attachment.

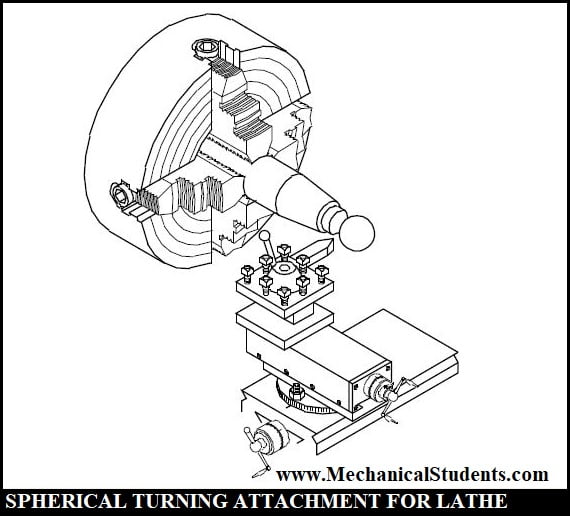

Spherical Turning attachment for Lathe:

The spherical turning attachment was used in center lathes for machining concave, convex, and spherical surfaces.

This attachment is generally mounted on the cross slide and the tool is to be placed in the tool post it can make a certain angle w.r.t. the workpiece and thereby the components can be manufactured.

This is the detailed information of Lathe Machine Accessories and Attachments. If you have any doubt, you can feel free to ask us and we will reply to you as soon as possible.

FAQs:

What is the function of a lathe machine?

What are the lathe accessories?

What are the lathe attachments?

Spherical attachment for lathe.

More Resources:

Surface Grinding Machine

Lathe Machine

NC Machine

CNC Machine

Milling machine

Drilling Machine

Radial Drilling Machine

Planer Machine

Shaper Machine