Machine Molding Operations and Hand Molding Operations in Casting Process [With PDF]

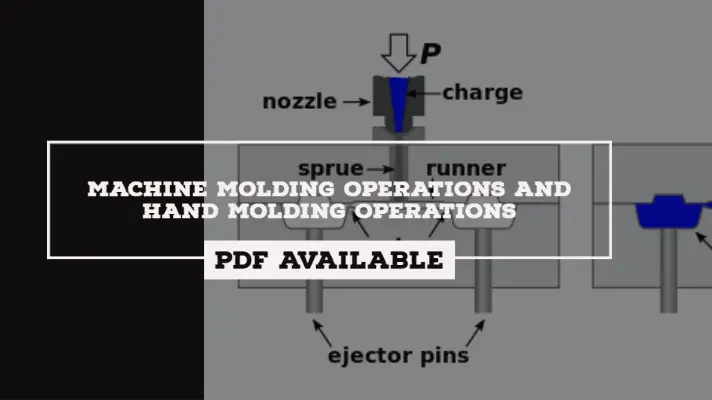

In order to prepare a component in the casting process, the mold is used. The molten metal is poured into the mold cavity and is allowed for solidification. In order to prepare the mold, two methods are generally used.

Therefore in this article, I will be explaining the Top 4 Machine Molding operations used in the Casting Process in a detailed manner.

Molding Methods:

There are two types of Molding Methods:

- Hand Molding method

- Machine Molding method

The hand Moulding method is generally used in institutions whereas Machine Moulding method is used in industrial applications.

1. Hand Molding Method used in Casting Process [Ramming and Compressing]:

Whatever the force required for ramming and compressing of molding sand, if it is obtained from a human hand, then it is called as hand molding.

In this article, I will be explaining about the Hand Molding Method used in Casting Process in a detailed manner.

The properties of Hand Moulding method are as follows:

- It is the cheapest method of mold making operation.

- Complex shapes of the patterns will be easily used in mold making without any damages to the pattern.

- Strength and Hardness of the mold are non-uniform because of the non-uniform force applied by hand.

- The production rate is low.

The other method used for preparing the mold is Machine Molding method. It generally consists of 4 operations. By using these operations only, the mold can be prepared.

2.Machine Molding Operations:

The molding operations which are performed with the help of machine are called Machine Molding Operations.

The 4 Machine Molding operations used in the casting process are as follows:

- Jolting Operation

- Squeezing Operation

- Jolting and Squeezing Operations

- Sand Slinging Operation

The detailed explanation of Jolting operation is as follows.

Jolting Operation:

- A sand-filled mold is raised to a certain amount of height so that it possesses potential energy.

- When it is allowed to form freely on to the ground, the Potential energy is converted into Impact energy and Impact loading which is acting on to the ground.

- Whereas the equal and opposite reaction impact load produced by the ground will be acting on to the mold for ramming and compressing of the mold called as Jolting Operation.

- Because the force applied by the ground may not be transmitted up to the top of the mold, hence the bottom of the mold is attaining higher strength and hardness.

- But the top of the mold is possessing lower strength and hardness.

Squeezing Operation:

- A plate is placed on the top of the sand mold and applies the load by using hydraulic or Mechanical press. So, that ramming or compressing of molding sand will be taking place.

- With the Squeezing operation, higher strength and Hardness of the mold is obtained on top and lower strength and hardness is obtained at the bottom.

- By combining Jolting and Squeezing operation, it is possible to attain higher strength and hardness throughout the mold.

- But, Always Jolting will be done first and then Squeezing.

Jolting and Squeezing Operations:

- The Jolting and Squeezing methods will give the uniform strength and hardness if the height of the mold is less than 200 mm.

- If the height of the mold is greater than 200 mm, the top and bottom will be getting higher strength but the middle of the mold is at a lower strength.

Sand Slinging Operation:

To get the uniform strength throughout the mold with whatever may be the height of the mold, the best process is Sand Slinging Operation.

- In Sand slinging operation, small quantities of molding sand will be thrown into the mold with a certain amount of force so that localized ramming action will be taking place and it gives the uniform strength and hardness of the mold with whatever may be the height of the mold.

- The Sand Slinging equipment is costly and also when the molten sand is thrown on to the projection, it may damages the projection present on the pattern.

- Hence this method cannot be used for producing the molds with a pattern having projections and Extinctions.

This is the complete explanation of Machine molding operations in a detailed way.

References:

- Introduction to molding processes | Make

- Types of Molding Processes - Sciencing