Drilling Machine: Definition, Types, Parts, Working Principle, Operations, Advantages, Disadvantages, Applications [PDF]

In the last class, we had discussed the Milling Machine and its operations in a detailed way whereas, in today's article, we will discuss the concepts of Drilling Machining along with its parts, working principle advantages, disadvantages, and applications.

Drilling Machine:

It is a machine which is used to drill the holes on the components or workpiece with the help of drill bits.

The drill bits are also called as Multi-point cutting tools which can have their rapid impact on the Material Removal Rate (MRR) i.e. a single-point cutting tool (like the one used in a lathe machine) can remove the material slowly whereas, a multi-point cutting tool removes the material at a faster rate and thereby increases MRR.

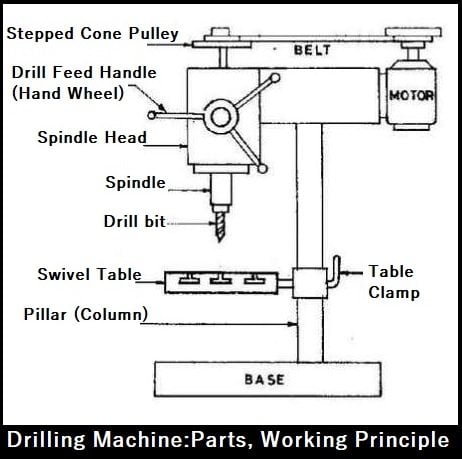

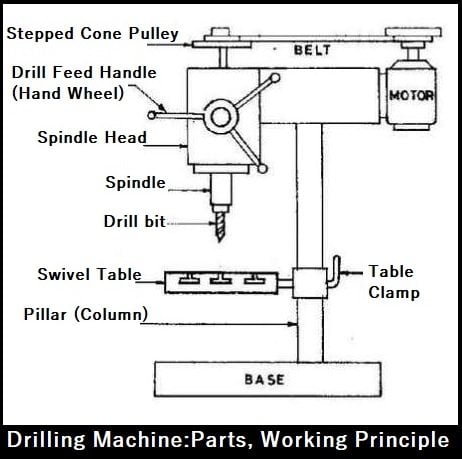

Line Diagram of Drilling Machine:

The line diagram of Drilling machine is shown below.

Parts of Drilling Machine:

The parts of Drilling Machine are as follows.

- Base

- Vertical Column

- Swivel Table

- Power Transmission system (Stepped Cone Pulley)

- Drill Feed Handle (Hand Wheel)

- Chuck

- Table Clamp

- Drill bit

- Spindle

Explanation for the parts of Drilling Machine:

Base:

The base is made up of Cast Iron which has the capability of high compressive strength, good wear resistance, and good absorbing capability (i.e. absorb the vibrations induced during working condition) and for these reasons, it acts as a base to the drilling machine.

Vertical Column:

It is exactly placed at the center of the base which can act as a support for rotating the Swivel table and holding the power transmission system.

Swivel Table:

It is attached to the column which can hold the machine vice in the grips and thereby, the workpiece is fixed in the machine vice to carry out the drilling operation.

The Swivel table can move up and down by means of rotational motion and can be locked to the column by means of locking nut.

Power Transmission system:

It consists of motor, stepped pulley, V-belt, and the Spindle. The power transmission is explained in the working of the drilling machine.

Drill Feed Handle:

By the rotation of hand-wheel, the spindle moves up and down in the vertical direction in order to give the necessary amount of feed to the work.

Here, the rotational motion is converted into linear motion by means of a Rack and Pinion mechanism which was explained below.

Chuck:

It is used to hold the workpiece. Generally, 3 jaw chuck is used for holding circular components and 4 jaw chuck is used for holding rectangular components.

Table Clamp:

It is used to lock the swivel table at the desired location.

Spindle:

It is used to hold the drillbit along with jaws.

Drill bit:

It is the major part of this machine and is used to remove the material in the form of holes from the surface of the workpiece.

Working Principle of Drilling Machine:

When the power is given to the motor, the spindle rotates, and thereby the stepped pulley attached to it also rotates. On the other end, one more stepped pulley is attached and that is inverted to increase or decrease the speed of the rotational motion.

Now, a V-belt is placed in between the stepped pulleys so as to drive the power transmission. Here a V-belt is used instead of a flat belt, in order to increase the power efficiency.

Now the drill bit also rotates which was placed in the chuck and which was in connection with the spindle. As the Pulleys rotates, the spindle also rotates which can rotate the drill bit.

Now, by the rotation of hand-wheel, the spindle moves up and down in the vertical direction in order to give the necessary amount of feed to the work and this drill bit is used to make the holes on the component placed in the machine vice.

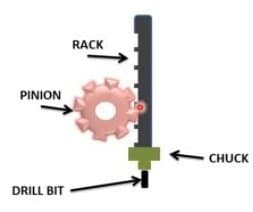

Drive Mechanism of Drilling Machine:

This drive mechanism is based on Rack and Pinion Mechanism.

When the hand-wheel is rotated, it is converting the rotational motion to the linear motion by means of rack and pinion.

The setup consists of Rack(has fine grooves), Pinion, Chuck and the Drill bit. The drill bit has placed in the chuck and the chuck is connected to rack and when the hand-wheel rotates, the Pinion is inserted in the grooves of Rack [shown in the below fig.] and thereby the rotational motion is converted to linear motion and as this mechanism is running by means of Rack and Pinion called as Rack and Pinion mechanism.

Types of Drilling Machines:

Below is the list of drilling machines which are used in the industries for the production of the materials.

- Radial drilling machine

- Upright drilling machine

- Multiple Spindle drilling machine

- Deep hole drilling machine

- Sensitive drilling machine

- Portable drilling machine

- Gang drilling machine

The explanation of above types of drilling machines are as follows.

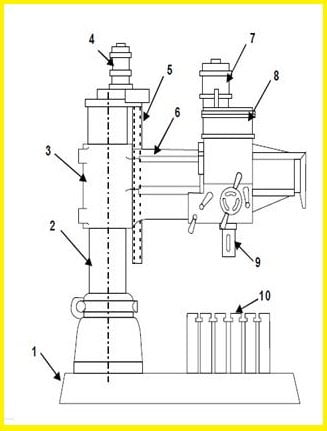

Radial Drilling Machine:

A radial drilling machine is used to drill holes in the components but it is quite different from the general drilling machine. The radial drilling machine has an arm that can rotate in the given radius.

If the component is large and if it is not able to hold on the worktable, then the component has to be placed on the ground and by rotating radial arm, the operation is to be performed.

Upright Drilling Machine:

It is used to drill holes of Medium size in the components. It is heavier and bigger than the Sensitive drilling machine.

A large number of spindle speed and feed can be accessible for various types of works.

The Upright Drilling machine can have a drilling capacity range of 75mm diameter drills.

Multiple Spindle Drilling Machine:

As the name indicates, these drilling machines have multiple spindles that are away from each other.

This machine is used, when you want to drill a large number of holes on a single workpiece or making holes on individual workpieces.

By this operation, the production will be at a higher rate.

Deep Hole Drilling Machine:

These types of drilling machines are designed to drill deep holes in various components of automobiles such as connecting rods, Aircraft Landing Gear, Inside Bore of Hydraulic Cylinder, Fuel Injector Bodies, Oilfield Exploration Equipment, etc.

It has to make sure that the coolant has to be added during the removal of material from the components.

Sensitive Drilling Machine:

Here in the case of a Sensitive drilling machine, when the operator gives the feeding of the tool into the workpiece, it allows the operator to 'feel' or 'sense' the cutting action of workpiece w.r.t.the tool and that's the reason, it is called as Sensitive Drilling Machine.

It is also called a Bench Drilling machine which was explained at the beginning of the article.

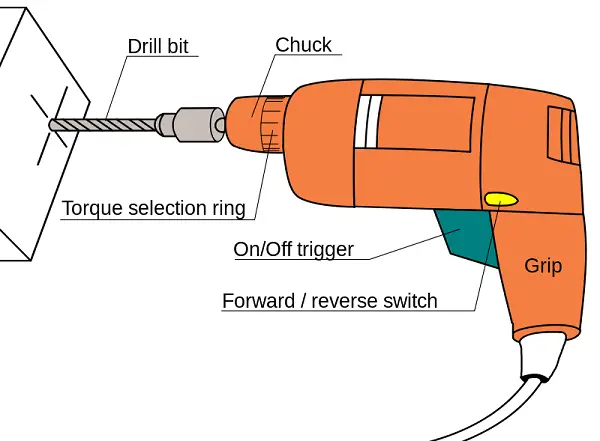

Portable Drilling Machine:

The portable drilling machine works in the similar way of bench drilling machine, but the difference is, the portable drilling machine can be taken to the different workplaces along with you and that's the reason it is called as portable drilling machine.

Whereas, the bench drilling machine can do various operations, but it can stand at one place and it is not movable w.r.t. the workplaces.

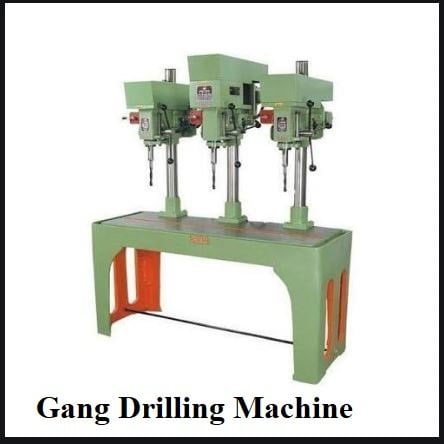

Gang Drilling Machine:

As the name indicates that it has a gang of drill heads with individual motors attached to the vertical column and does multiple operations at a time.

It generally consists of 4-6 drill heads which are placed side by side which can do various operations like drilling, boring, reaming, tapping, etc.

Either you want to create a small hole or large, the multiple spindles does the operation.

Drilling Machine Operations:

The opertaions of drilling machine are as follows.

- Drilling

- Boring

- Reaming

- Tapping

- Spot facing

- Trepanning

- Honing

- Counter boring

- Counter Sinking

An Explanation for the Operations to be performed on Drilling Machines:

The explanation is as follows.

Drilling Operation:

The operation of making holes on the surface of the workpiece by the use of drill bit is called Drilling Operation.

Boring Operation:

The operation of enlarging an existing hole is called the Boring Operation. The existing hole was created by the drilling operation.

Reaming Operation:

The operation of sizing and finishing an existing hole with the help of a reamer is called Reaming Operation.

Reamer is a multipoint cutting tool having several cutting edges to finish the surface.

Tapping Operation:

It is the operation of creating internal threads by means of a cutting tool called Tap and the operation is called Tapping Operation.

Spot Facing Operation:

This is an operation of removing the chips from the surface of the hole such that proper seating of bolts takes place and this removal can be done through end mill cutter using a drilling machine.

Trepanning Operation:

Without drilling, a Trepanning operation is used for producing a large-size hole of more than 50mm in diameter. This Trepanning operation cannot be used for blind holes.

Honing Operation:

In this operation, the tool will rotate and reciprocate about its axis for producing very smooth holes.

This honing operation is mainly used for finishing the holes in the IC Engine cylinder.

Counterboring Operation:

The Counter boring operation is used to enlarge a particular portion of the hole.

Countersinking Operation:

The Countersinking operation is used to enlarge the end of the hole to give it a conical shape for a shorter distance.

These are the various operations that are performed on Drilling machines.

Let's know about the Advantages and Disadvantages of the Drilling Machine along with its applications.

Advantages of Drilling Machine:

The advantages of Drilling Machine are as follows.

- It requires less labor.

- High precision and accuracy will be maintained by the operator in Bench Drilling Machine whereas, in the case of Automatic drilling machine, high accuracy is maintained by the machine itself.

- It is easy to operate

- The maintenance is low.

Disadvantages of Drilling Machine:

The Disadvantages of Drilling Machine are as follows.

- As it makes rough holes during the drilling operation. Therefore, a medium surface finish can be expected but not a high surface finish.

- A small size workpiece that can fit on the worktable is machined whereas large size components cannot be machined.

- If there is an improper clamping between the drill and the workpiece, there will be a probability of breaking the drill bit.

Applications of Drilling Machine:

The applications of Drilling Machine are as follows.

- Surface mining

- Counter boring

- Countersinking

- Underground mining

- Tapping etc.

These are the different types of Drilling machines. Let's find its Advantages, disadvantages and applications in a detailed way.

More Resources:

Milling Machine

Lathe Machine

Grinding Machine