Difference between Shaper and Planer Machine [PDF]

In the last session, we had discussed various conventional machines such as Drilling machines, radial drilling machines, milling machines, lathe machines, etc. whereas, in today's article, we are going to discuss the Difference between Shaper and Planer machine in a detailed way. But before that let's see the definition of both Shaper machine and Planer machine.

Definition of Shaper Machine:

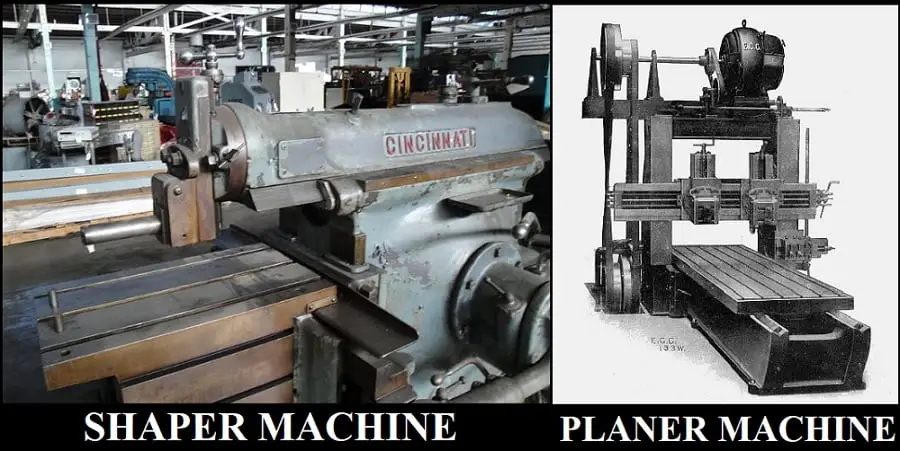

Shaper Machine is defined as the process of removing the material from the surface of the workpiece, fixed in the machine vice by a single-point cutting tool that reciprocates in linear motion across the workpiece. The material removed from the workpiece will be in horizontal, vertical, and angular planes by the single-point cutting tool.

Here in the Shaper machine, the workpiece is fixed in the machine vice, and the tool is under the motion.

Definition of Planer Machine:

Planer Machine is defined as the process of removing the material from the surface of the workpiece, by means of a tool which is fixed and the workpiece reciprocates along with it. As it also uses a single-point cutting tool, but the machinery is large compared to a shaper machine and can machine large components.

Here in the Planer machine, the Tool is fixed and the workpiece is under the motion.

Now let's see the difference between Shaper and Planer Machine in tabular form.

Shaper vs Planer:

The Difference between Shaper and Planer in tabular form was presented below.

| Shaper | Planer |

|---|---|

| Shaper Machine uses a single-point cutting tool for the operation. | Planer Machine also uses a single-point cutting tool for the operation and more than one tool also can be used. |

| A shaper is a light-duty machine. | A Planer is a heavy-duty machine. |

| Here in the Shaper machine, the workpiece is fixed in the machine vice, and the tool is under the motion. | Here in the Planer machine, the Tool is fixed and the workpiece is under the motion. |

| The shaper is smaller, lighter, and cheaper compared to Planer. | The Planer is larger, heavier, and costlier compared to the shaper. |

| The accuracy is less compared to the planer. | The accuracy is more compared to the Shaper. |

| It is not possible by the shaper to make deep cuts. | It is possible for the planer to make deep cuts. |

| Not possible for heavy feeds. | Possible for heavy feed. |

| Productivity is less w.r.t. time. | Productivity is more w.r.t. same time. |

| The Shaper machine just uses a single-point cutting tool for the operation. | The Planer machine is equipped with more than one tool for the operation. |

| The Power consumption by the Shaper is less. | The Power consumption by the Planer is more than the Shaper. |

| The shaper machine requires less floor space because the machinery is small compared to the Planer. | The Planer machine requires more floor space because the machinery is large compared to the Shaper. |

| A low skilled operator is required. | A high skilled operator is required. |

| It is intended for smaller jobs/components. | It is intended for larger jobs/components. |

| The Shaper Machine uses Quick Return Motion Mechanism to drive the ram. | The Planer Machine is driven by means of gear or hydraulic arrangement. |

So today we have learned the Difference between Shaper and Planer machines. I hope you understood the difference between these machines. We can see detailed information on them in future posts. If you have any doubts, you can comment on this post and we will reply to you within 24 hrs.

FAQs:

Which mechanism is used in shaper machine?

Which machine tool is known as the mother machine tool?

More Resources:

Surface Grinding Machine

Drilling Machine

Milling Machine

Radial Drilling Machine

NC & CNC Machine

References [External Links]:

- Lesson 13. Introduction to Shaper and Planar Machine

- Manufacturing Processes – II - Nptel