Extrusion Process: Definition, Types, Advantages, Disadvantages & Applications [PDF]

The extrusion process is widely used in the production of hollow pipes and tubes. In this article, we are going to discuss the Extrusion Process along with its Definition, Types, Advantages, Disadvantages & Applications in a detailed way.

Definition of Extrusion Process:

Extrusion is a compression process in which the work material is forced to flow through a die opening to produce a desired cross-sectional shape called an Extrusion process.

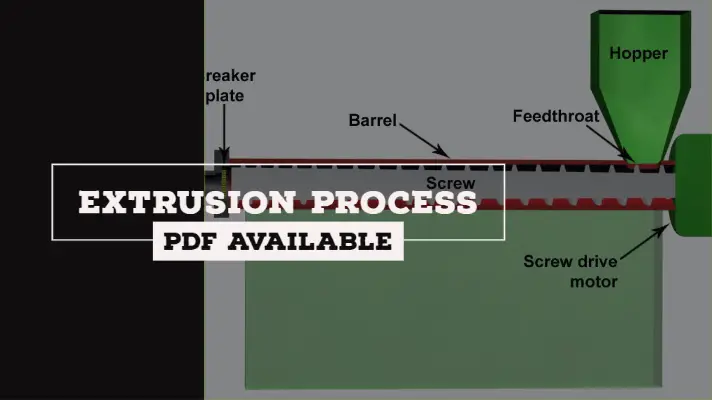

Working Principle of Extrusion Process:

In this process, the forces are applied on to the raw material by using a RAM in a closed container such that stresses induced in the material is greater than the flow stress of the material.

As the behavior of the material is like a fluid, the material can flow through the small opening available in the container, taking the shape and size remains the same as that of opening.

For example, Squeezing toothpaste out of a toothpaste tube.

To understand the working principle in a better way, we need to know about the types of the extrusion process.

Types of Extrusion Process:

There are two types of Extrusion process.

- Forward Extrusion or Direct Extrusion

- Backward Extrusion or Indirect Extrusion

Let me elaborate these types.

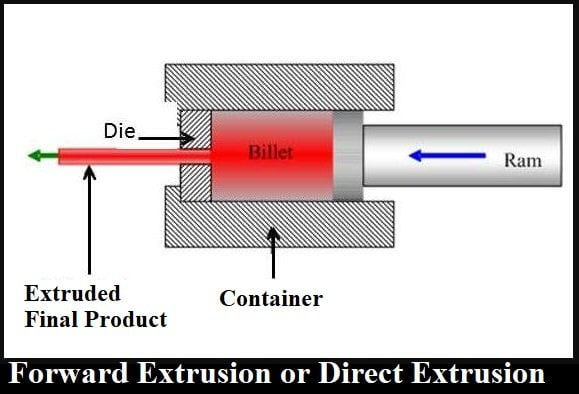

1. Forward Extrusion or Direct Extrusion:

Setup of the Forward extrusion consists of a die, ram, billet (work material), and the container.

In forward extrusion, the direction of movement of the Ram and extruded component are in the same direction.

In the case of Forward extrusion, every point of raw material has to travel against the container wall friction for the extrusion to be taken place.

Hence, the force required for Forward Extrusion is higher than the Backward Extrusion.

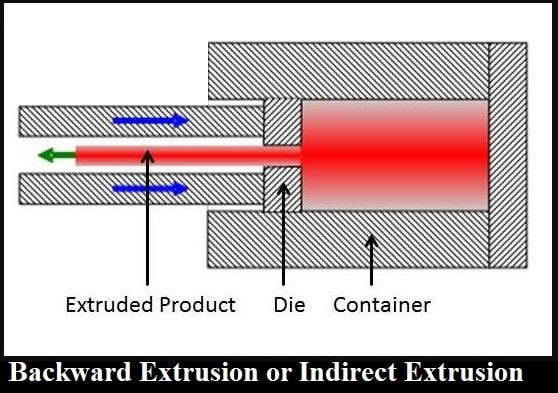

2. Backward Extrusion or Indirect Extrusion

The setup of backward extrusion consists of a die, ram, billet (work material) and the container similar to forward extrusion process.

In Backward extrusion, the direction of the movement of Ram and the extruded component is in the opposite direction.

In the case of Backward extrusion, the raw material can deform directly and the flow takes place through a die opening, and the required shape of the component can be obtained.

Hence, the force required for backward Extrusion is very much lower than the Forward Extrusion.

Advantages of the Extrusion Process:

So the advantages are:

- A consistent cross-section of the components can be obtained.

- The extrusion process exhibits a low cost compared to other processes.

- The post extrusion works can be done very easily because the extruded component is very hot after the extrusion process.

Disadvantages of Extrusion Process:

Here are some disadvantages:

- Undesirable residual stresses may produce after extrusion.

- Due to this, there is a variation of sizes takes place after extrusion, because the extruded component is very hot.

- Due to this unpredictable expansion, the manufacturers have to accept a significant level of deviation compared to the original part.

- Heavier equipment is needed.

Applications of Extrusion Process:

The applications are as follows.

- It is widely used in the production of hollow pipes and tubes.

- Aluminum extrusion is used in structural work in many industries.

- The extrusion process is used to produce frames, windows, doors, etc. in the automotive industries.

- Plastic objects can be produced widely by an Extrusion process.

More Resources for You:

Injection Molding process

Blow Molding process

Compression Molding Process

Rolling process

FAQs:

What is Extrusion Process?

What is extrusion Moulding process?

Where is extrusion used?

This is the detailed explanation of the Extrusion Process. If you have any doubts, notify us so that we can solve it soon.