Compression Molding Process: Working Principle, Advantages, Disadvantages, Applications & Defects [Notes with PDF]

Hello readers, in this paper we will be going to give you a detailed explanation of the Compression Molding Process along with its Working Principle, Advantages, Disadvantages, Applications and, Defects is presented below.

What is Compression Molding Process?

Compression Molding is a molding method in which the molding material(especially Thermoplastics or Thermoset plastics) is generally preheated and is placed in a mold cavity. The heating or cooling given to the cavity depends upon the type of plastic used.

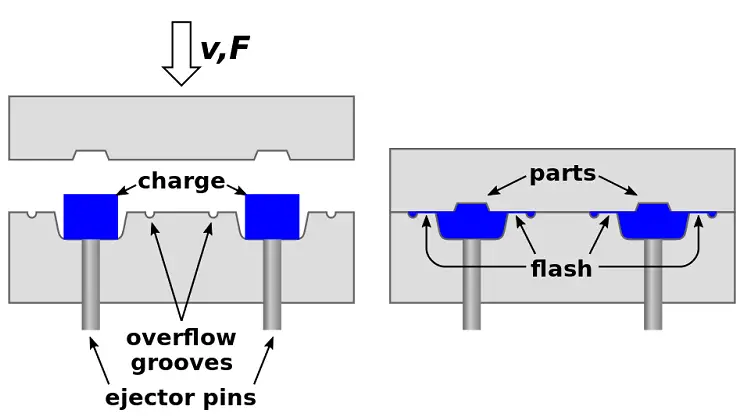

Compression Molding Diagram:

The below diagram represents Compression Molding Process for both Thermoplastics as well as Thermoset Plastics.

Compression Molding Process Working Principle:

The working principle of Compression Molding process is as follows.

It is used for both thermoplastics and thermosetting plastics, but I can classify them under two cases and they are as follows.

Case 1: For Thermosetting Plastics

- In this Process, the Thermoset liquid will be kept in the mold of a required shape of the component and is subjected to the heating process.

- During heating, the liquid will undergo the following changes i.e. liquid will undergo in the form of a gel, and by the application of pressure, it turns to solid.

- After that, the Compression load is applied at the gel condition of the liquid so that the shaping of the component takes place.

- Heating converts the liquid into solid whereas, compression load will give the shape to the component.

Case 2: For Thermoplastics

- The Thermoplastic molten liquid will be kept in the mold of the required shape of the component and subjected to compression followed by a cooling process of the mold.

- Compression gives the shape of the component whereas cooling converts the molten liquid into solid.

- Density and the Strength of the plastic can be controlled by varying the compression load “P”.

- Small and simple shapes of the component can be produced with uniform density.

- Larger and complex shapes of the components are difficult to produce with uniform density.

- Difficult to insert metal pieces in the plastic part during the production of the component.

This is the working principle of the Compression molding process for both types of plastics. Let's know the advantages and disadvantages of the Compression Molding process along with its applications.

Advantages of Compression Molding Process:

The advantages of Compression Molding process are as follows.

- It exhibits good surface finish.

- The wastage is relatievely very small.

- The initial setup cost is low.

- It can be applied to composite thermoplastics with randomly orientated fiber mat, woven fabrics etc.

- It is suitable for manufacturing large and intricate parts.

Disadvantages of Compression Molding Process:

The disadvantages of Compression Molding process are as follows.

- The repetitive nature of the compression molding process makes the molds to be damaged.

- This molding process is not suitable for making complex parts.

- The labor cost is higher in this molding process.

- The wastage of thermoset plastics is more compared to thermoplastics.

Applications of Compression Molding Process:

The applications of Compression Molding process are as follows.

- Outer envelopes of a washing machine

- Refrigerators

- Automotive Exterior Panels

- Gaskets

- Helmets

- Automobile auto parts etc.

Defects of Compression Molding Process:

This is the detailed explanation of the Compression Molding Process. If you have any doubts, please let us know, we can solve it soon.

More Resources:

Injection Molding Process

Blow Molding Process

References [External Links]:

- Compression Moulding Process-PDF

- What is the difference between molding and casting?