Rolling Process: Definition, Working, Rolling Mills, Advantages, Disadvantages & Applications [PDF]

Rolling is a metal forming process in which the deformation takes place under the application of Compressive forces between the rollers. In this article, we are going to discuss a detailed presentation on the Rolling Process with its Principle, Working, Types of Rolling Mills, Advantages, Disadvantages & Applications.

Let's dive into the article of Rolling Process...

What is a Rolling Process?

The rolling is one of the metal forming processes in which the material (metal strip) is compressed in between the two or more rotating rollers such that the stress responsible for changing the shapes of the material is only by compressive stress.

This process reduces the actual thickness to the desired thickness.

Types of Rolling Process:

Rolling is classified into two types according to the temperature of the metal being rolled. One is the hot rolling and the other is cold rolling.

Hot Rolling Process:

If the temperature of the metal is above the recrystallization temperature, then the process is known as hot rolling.

Cold Rolling Process:

If the temperature of the metal is below the recrystallization temperature during rolling, then the process is known as cold rolling.

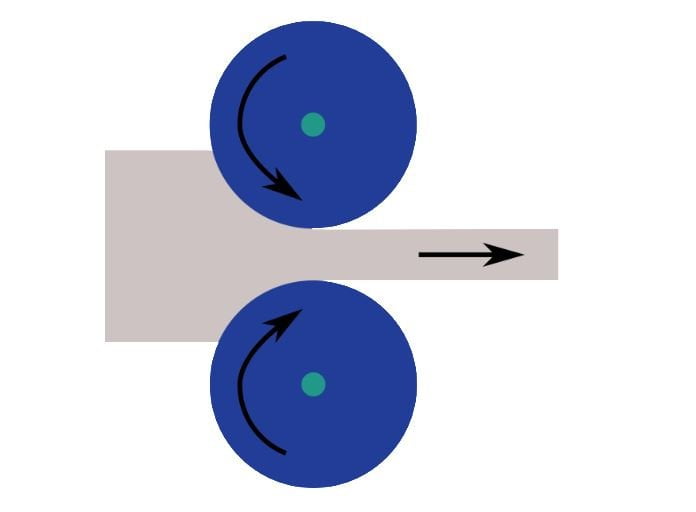

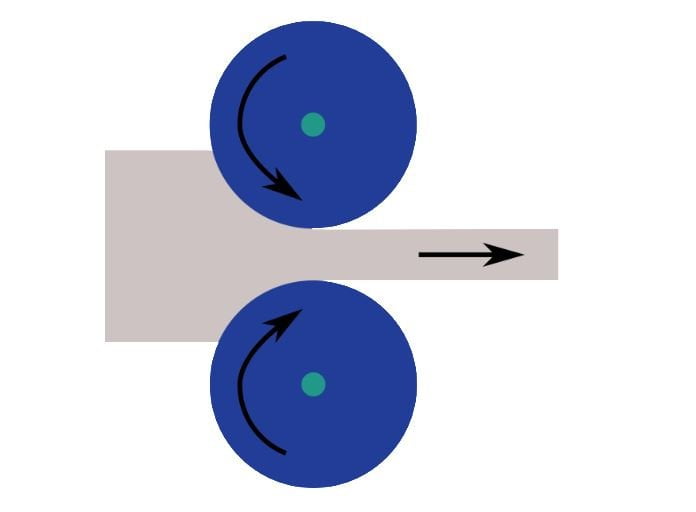

Rolling Process Diagram:

The basic diagram of Rolling is shown below.

Working Principle of Rolling Process:

In Rolling operation, the metal strip or the material is to be placed in between two rollers such that material is compressed by the opposite forces of the rollers to make the material to a uniform thickness.

The presence of friction between rollers and the strip is making it pull the strip into the rollers without applying any pulling and pushing.

By the application of rolling, the length of the material increases and thickness reduces without any change in the width of the workpiece.

Does anyone know, how we get a uniform thickness of the workpiece by Rolling Process?

During rolling, there might be a chance that the workpiece can bend due to the unequal compression on the different parts of the material and this can be solved as follows.

How to avoid bending during Rolling?

To avoid the bending of the strip during rolling, the surface velocity of both the rollers must be equal.

I.e. Vtop roller = Vbottom roller

=>(πDN) top roller= (πDN)bottom roller

=>(DN) top roller= (DN)bottom roller

If D top= D bottom =>Nt = N [Here D top=Dia of Top Roller & D bottom = Dia of bottom Roller]

Therefore Nt = Nb.

To ensure that the contact area between the rollers and the strip at both sides, the dia of both sides must be the same. hence the speed of both the rollers will also be the same.

If one roller is rotating with N speed and the other is rotating with N1 speed, then we will get incomplete compression of the roller.

Therefore, it is recommended to use the same speed for both the rollers.

Types of Rolling Mills:

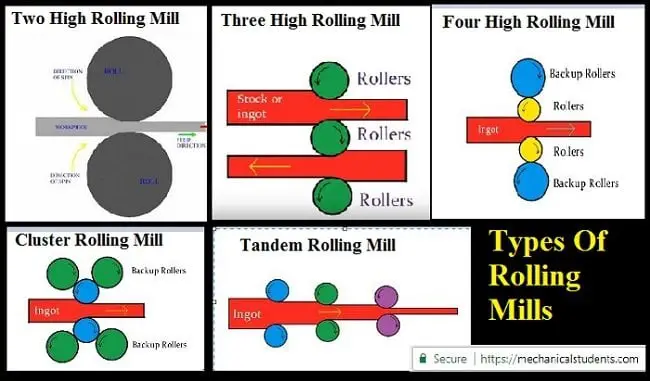

Metal Rolling is classified into 5 types and they are as follows.

- Two High Rolling Mills

- Three High Rolling Mills

- Four High Rolling Mills

- Cluster Rolling Mills

- Tandem Rolling Mills

An Explanation for the Types of Rolling Mills:

A detailed explanation for the Types of Rolling Mills is as follows.

Two High Rolling Mills:

- It consists of two rolling mills which are rotated in opposite directions to each other.

- The material is to be passed in between these two rolling mills such that the compressive forces can changes its thickness from the original.

The diagram for the rest of the rolling mills is shown below.

Three High Rolling Mills:

- Three Rolling mills are arranged one on the other in the vertical direction such that two metal strips can pass in between the rollers at a time and shape change(reduce their thickness) takes place.

- By this, productivity increases.

Four High Rolling Mills:

- Four Rolling mills are arranged one on the other in the vertical direction such that only one metal strip can pass in between the rollers and shape change(reduce their thickness) takes place.

- The Upper and lower rollers are just for support(Backup Rollers) whose diameter is bigger than the other two rollers are held in Vertical direction, one on the other, and the material is to be passed in between the two small rollers and shape change takes place.

- This type of rolling is applicable to the high thickness materials where high compressive forces are needed to reduce the thickness of the material.

Cluster Rolling Mills:

- The material is to be passed through the two small rollers which are in support of Four backup rollers.

- This type of rolling is applicable to the high thickness materials where high compressive forces are needed.

Tandem Rolling Mills:

- In this type of rolling mill, the material is to be continuously passed through the pair of rollers so that we can obtain the desired shape and thickness.

- Applicable to High thickness materials.

This is the detailed explanation on are different types of rolling mills.

Advantages of Rolling Process:

The advantages of Rolling process are as follows.

- By rolling, uniform dimensions of the components can be obtained.

- It uses the same tool in the sense, the same rollers are responsible for the production of various components.

- Close tolerance is possible for the components in the rolling.

- high-speed production takes place in the rolling.

Disadvantages of Rolling Process:

The disadvantages of Rolling process are as follows.

- The cost of equipment is high.

- It is suitable for large scale production only.

- Poor surface finish and thereby we need to secondary operations like finishing etc.

Applications of Rolling Process:

The applications of Rolling process are as follows.

- Rolling is used for making rods.

- By rolling, Large length cross sections are produced.

- Steel sheets and plates are made by the rolling.

- Cement Kilns are produced from the rolling only.

- It is used in automotive industries for manufacturing various parts.

This is a detailed explanation of the Rolling Process. If you have any doubt, feel free to ask in the comments section.

FAQs:

What is the Definition of Rolling Process?

How many Types of Rolling Process are present?

What are the Types of Rolling Mills?

1. Two High Rolling Mills

2. Three High Rolling Mills

3. Four High Rolling Mills

4. Cluster Rolling Mills

5. Tandem Rolling Mills

What are the applications of Rolling Process?

References [External Links]:

- Metalworking - an overview | ScienceDirect Topics

- Metalworking throughout history - The Fabricator