Classification of Different Welding Processes [With PDF]

Welding is a process of joining two or more similar or dissimilar metals with or without the application of heat, with or without the application of pressure, with or without the application of filler material.

Therefore, In this article, I will be explaining all the Classifications of the Welding Process in detail with the help of a tree diagram.

Classification of Welding Process:

The welding Process is broadly classified into three types:

- Fusion Welding

- Non-Fusion Welding

- Resistance Welding

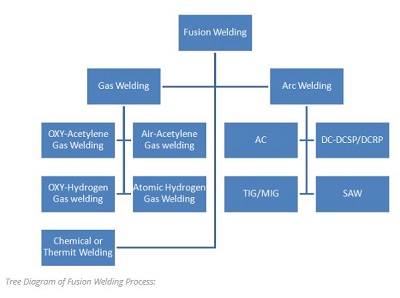

Fusion Welding Process:

By melting of parent material, if the joint is produced called as Fusion Welding Process.

Fusion Welding Process is further classified as:

- Gas Welding

- Arc Welding

- Chemical or Thermit welding

1. Gas Welding Process:

By burning of gases, the heat required for melting of plates is obtained called Gas welding operation.

Gas Welding is further classified as follows:

- OXY-Acetylene Gas Welding

- Air-Acetylene Gas welding

- OXY-Hydrogen Gas welding

- Atomic Hydrogen Gas Welding

2. Arc Welding Process:

By using electric arc, if the heat required for melting of plates is obtained called as Arc Welding Operation.

Arc Welding is further classified as follows:

- AC Welding

- DC Welding - Classified as DCSP/DCRP

- TIG Welding - Tungsten Inert Gas Welding

- MIG Welding - Metal Inert Gas Welding

- SAW Welding-Submerged Arc Welding

3. Chemical Welding Process:

By using Exothermic Chemical Reaction, if the heat required for melting of plates is obtained called as Chemical welding process.

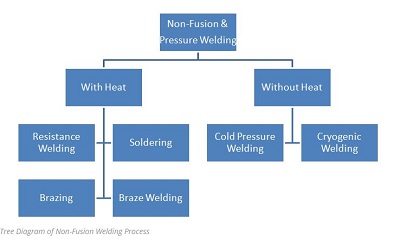

Non-Fusion Welding Process:

Without melting of parent material, if the joint is produced called a Non-Fusion welding process.

Pressure welding:

With the application of pressure, if the joint is produced called a Pressure welding operation.

1. Cold Pressure Welding:

The joining of two metals at room temperature with the application of a large amount of pressure is called cold pressure welding.

2. Cryogenic Welding:

If two metals are joined at a temp less than -183 ̊C and with the application of a large amount of pressure called Cryogenic welding.

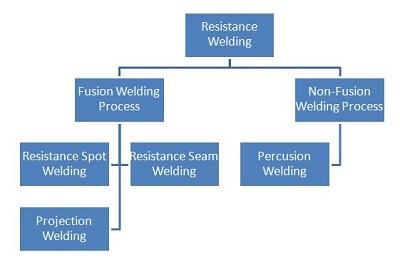

Resistance Welding Operation:

Even though resistance welding is classified under the non-fusion Welding Process but it is a fusion pressure welding operation.

- The heat required for melting and joining of the plates is obtained through the electrical resistance of the circuit.

- The electrode material is selected such that it should have lower electrical resistance, higher melting point temperature, and high strength.

- The most commonly used electrode materials in resistance welding are Copper, Tungsten, Copper-Tungsten alloy.

Resistance Welding Operation is classified as

- Fusion Welding Process

- Resistance Spot Welding

- Resistance Seam Welding

- Projection Welding

- Non-Fusion Welding

- Percussion Welding

On the whole, these are the different types of Welding processes in detail. I hope this article is helpful to you.

More Resources

Resistance Welding

Gas Welding

Electric Arc Welding