Non-Traditional Machining: Definition, Types, Advantages and Limitations [PDF]

Non-Traditional Machining Method is an advanced method used to overcome the problems of Traditional Machining methods. The Non-Traditional Machining methods include Ultrasonic Machining, Laser Beam Machining, Water Jet Machining, Abrasive Water Jet Machining, Electron Beam Machining, etc. which were presented in this article in a detailed way.

The non-Traditional Machining method is an advanced method used to overcome the problems of Traditional Machining methods. In this article, a detailed explanation of Non-Traditional Machining was presented.

These limitations must and should know by a Mechanical Engineering Aspirant to understand the Non-Traditional Machining Methods in an easier manner.

Limitations for the occurrence of Non-Traditional Machining Methods:

- The tool must be at least 30 to 50% harder than the workpiece material but the workpiece itself is very hard, there is no cutting tool available harder than the one-piece material. For example, die Steel, Tool Steel, tungsten, etc.

- Poor machinability material can't be machined by a conventional method. For example, Alloys

- The machinery of highly brittle material like glass, ceramic, etc. is not possible.

- Machining of very soft material like Rubber is not possible by a conventional method.

- It is not possible to produce very small holes less than 1 mm in conventional by the drilling operation.

- Small size noncircular holes are not possible by broaching operation.

- Producing Complex, Concave curvature components like turbine blades is not possible by conventional methods.

- Making the zigzag hole in the component is not possible with conventional methods.

Points to be noted during machining operation:

- Mechanism of chip formation

- Tool material

- Medium

- Wear ratio

- Advantages

- Disadvantages

- Applications

Methods of Non-Traditional Machining:

- Ultrasonic machining Process

- Electrical discharge machining Process

- Electrochemical Machining Process

- Water jet machining Process

- Abrasive waterjet machining Process

- Electron beam machining Process

- Laser beam machining Process

- Electrochemical Grinding Process.

This is the complete explanation about 8 Limitations and Methods You Must know for the Occurrence of Non-Traditional Machining Methods in a detailed manner.

Detailed Explanation of Non-Traditional Machining Processes:

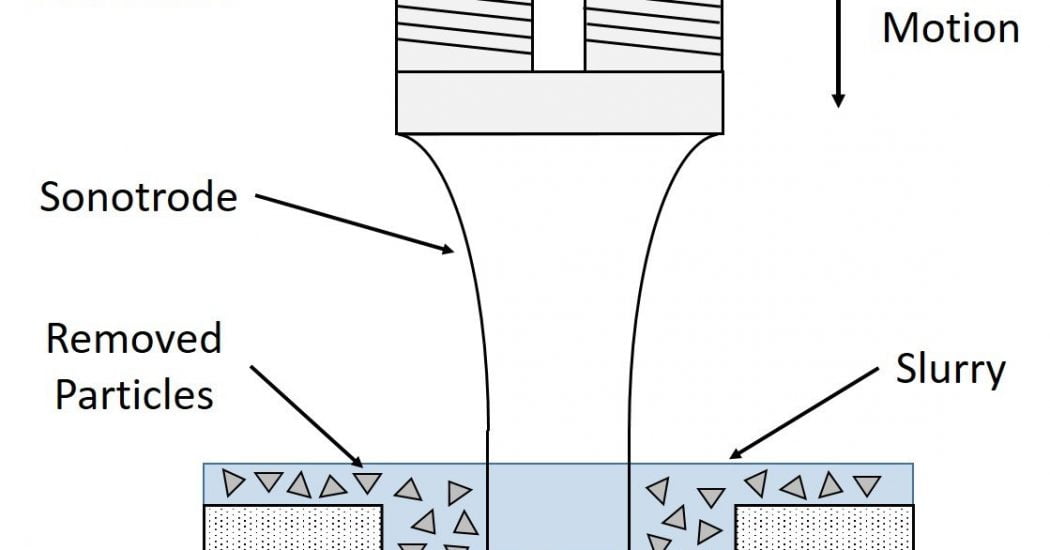

1. USM (Ultrasonic Machining) Method:

It is one of the types of Non-Traditional Machining methods which produces Circular, non-Circular holes of very small size is <1mm size can be produced by using this Ultrasonic Machining Method.

When very frequency vibrations are applied to the tool, the tool is vibrating at a very high frequency. This tool will induce impact loads onto the abrasive particles which in turn induces impact loads onto the workpiece.

READ HERE THE COMPLETE GUIDE ON ULTRASONIC MACHINING PROCESS

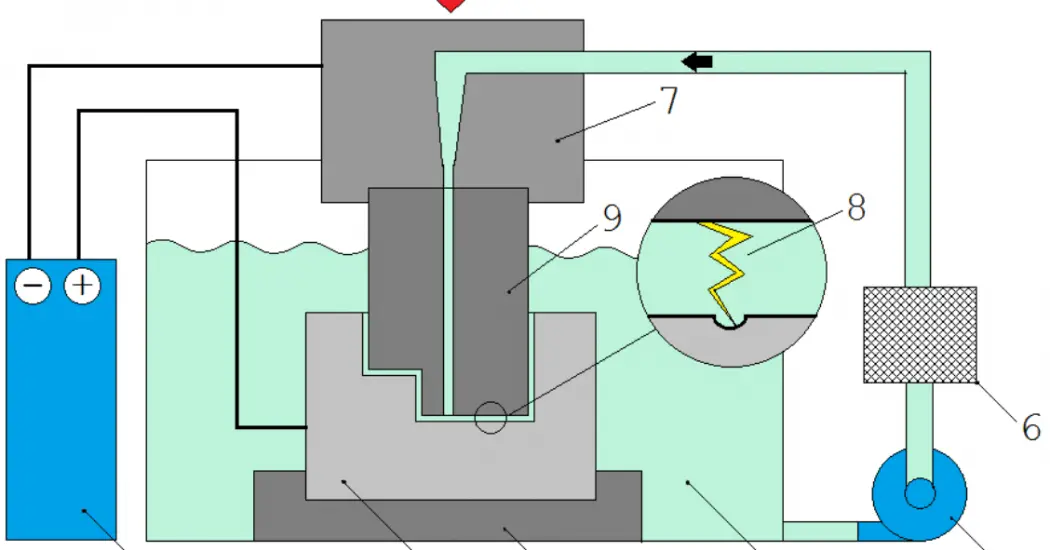

2. EDM (Electrical Discharge Machining) Process:

It is also known as Spark Machining or Spark Eroding process.

In this process, electrical energy is used to generate the Spark between the tool and workpiece submerged under the dielectric medium so that material removal takes place from the surface of the workpiece by local melting or Vaporization.

The Optimum gap between the tool and the workpiece is 0.03 mm.

Voltage – 70V

Electrolyte used: Dielectric Fluid (Kerosene).

The dielectric fluid in the normal form acts as an insulator whereas at proper voltage or increase in voltage makes the dielectric fluid is Ionized.

READ HERE THE COMPLETE GUIDE ON EDM PROCESS

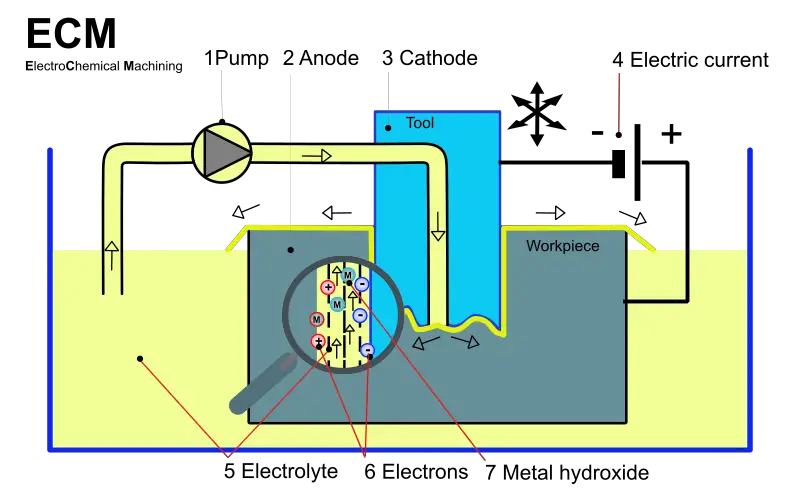

3. ECM (Electro Chemical Machining) Process:

In this process, the combination of electrical energy and chemical energy makes the removal of material from the surface of a workpiece. It works on the principle of Faraday’s law of electrolysis.

Principle-Faraday’s law of electrolysis: The mass of a substance deposited or liberated at any electrode on passing a certain amount of charge is directly proportional to its chemical equivalent weight.

Electrolyte used: NaCl (Conducting Electrolyte).

Wear Ratio: Infinity (because of no Tool Wear)

READ HERE THE COMPLETE GUIDE ON ECM PROCESS

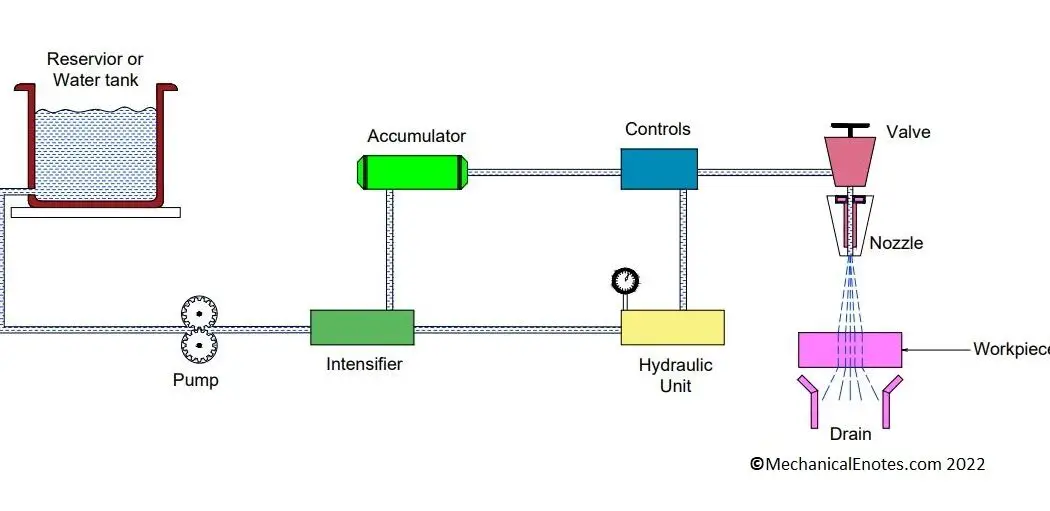

4. WJM (Water Jet Machining) Process:

- When very high-pressure water is passing through the convergent nozzle the pressure energy is converted into velocity energy or kinetic energy.

- Therefore the water is coming out from the nozzle at a very high velocity which is obtained to be 200 to 400 m per second.

- When this high-velocity water Jet is impinging onto the workpiece, the continuous impact load is acting onto it.

- Therefore very soft materials will experience plastic deformation and fracturing.

- From the above, the mechanism of material removal is due to plastic deformation and fracturing and also called an Etching process.

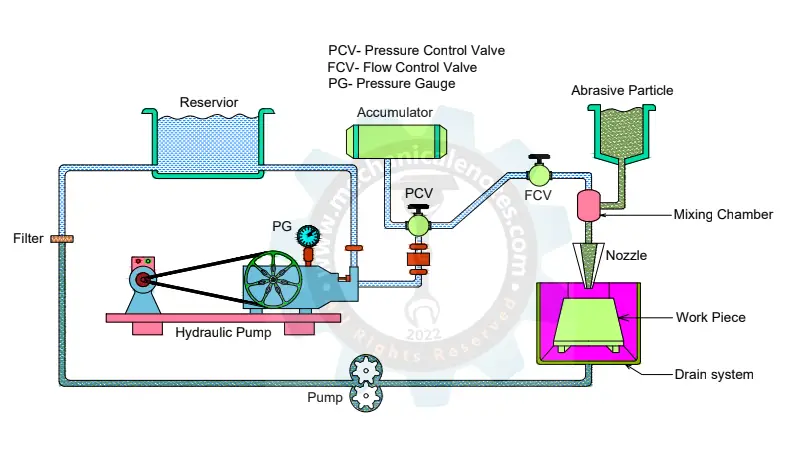

5. AWJM (Abrasive Water Jet Machining):

It is advanced in Water Jet Machining Process which includes Abrasives as a medium. A detailed explanation of Abrasive Water Jet Machining was presented below.

To overcome the second disadvantage of water jet machining, the abrasive particles will be added into the water so that the abrasive particles also come out from the nozzle at a very high velocity.

Therefore the optimum percentage of abrasives will be about 40 to 60%.

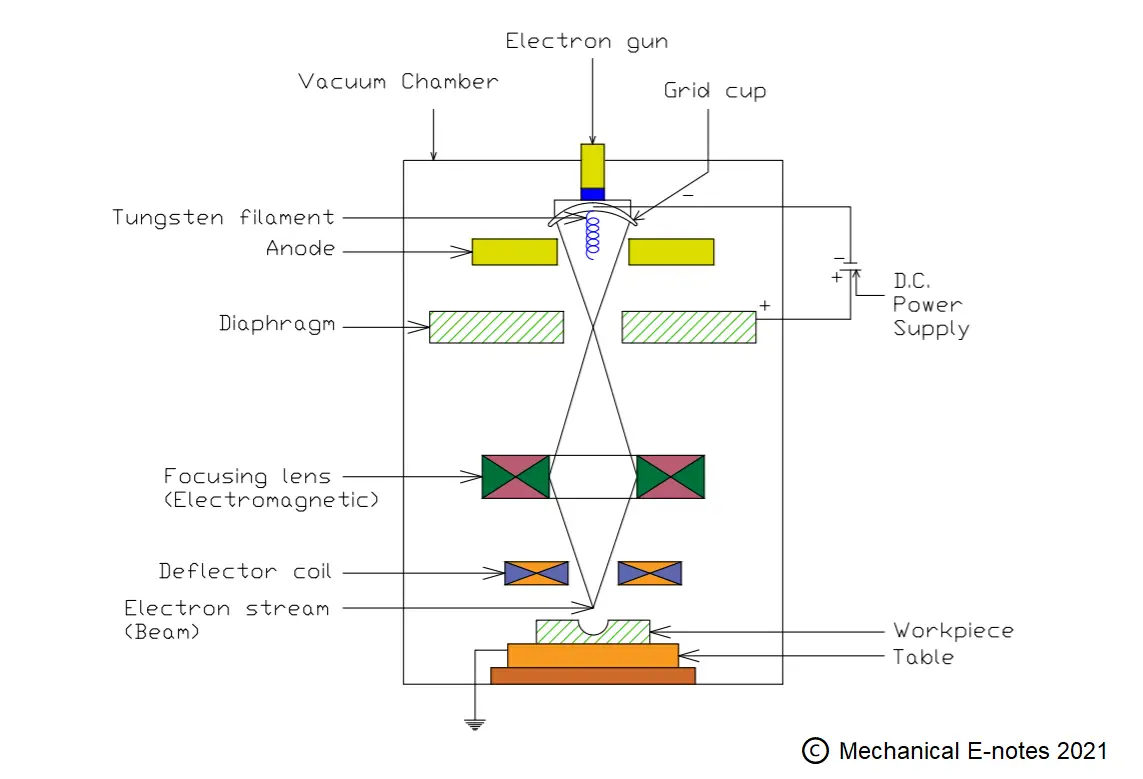

6. EBM (Electron Beam Machining) Process:

Electron beam machining also comes under one of those Non-traditional machining methods where highly dedicated accuracy is maintained. The brief explanation of EBM was explained below in a detailed manner.

- When a very high voltage power supply is given to the electron gun, it is producing very high-velocity electrons in all directions.

- By using a magnetic lens or the deflector, all these high-velocity electrons are collected and formed like a beam of electrons having a cross-section area less than 0.05-millimeter square.

7. LBM (Laser Beam Machining) Process:

When the power supply is given to the laser gun it is producing very high-intensity electromagnetic waves in the form of a beam called a laser beam with a wavelength ranging from 0.1 to 70 micrometers.

When this high-intensity electromagnetic wave beam is incident on the workpiece, the electromagnetic wave energy is converted into heat energy based on surface phenomena radiation heat transfer.

So this is the definite guide on Non-Traditional Machining Processes, I hope you liked it, feel free to share your thoughts in the comment section.