What is Ultrasonic Machining Process? [With PDF]

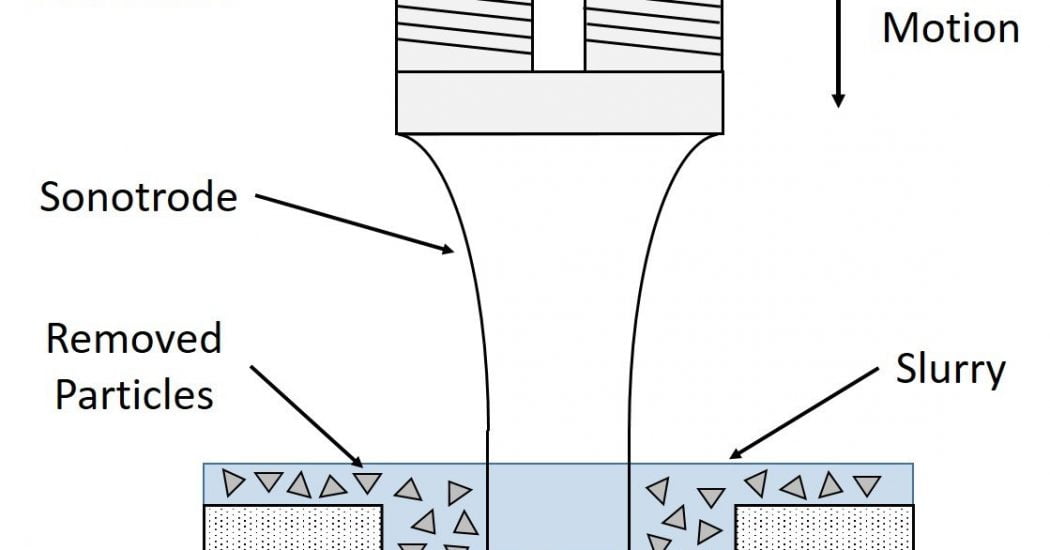

Ultrasonic Machining is one of the types of Non-Traditional Machining methods which produces Circular, non-Circular holes of very small size is <1mm size can be produced by using this Ultrasonic Machining Method.

When very frequency vibrations are applied on to the tool, the tool is vibrating at a very high frequency. This tool will induce impact loads on to the abrasive particles which in turn induces impact loads on to the workpiece.

If the workpiece is a highly brittle material and because of a very smaller size of the abrasive particles, the area on which impact loads acting is very small.

Therefore without Breaking the workpiece, the fracturing is taking place in a smaller area of the workpiece. The chips produced due to the fracturing will be moving along the abrasive slurry. From the above, the mechanism of chip formation is brittle fracturing.

Explanation of Ultrasonic Machining:

- During machining, the equal and opposite reaction, impact loads produced by the workpiece will be acting on to the tool, so that if the tool is made by using the hard material, the brittle fracturing is taking place in the tool also and the tool wear becomes higher.

- To minimize this, the tool must be made by using a material which has very high softness(ductility).

For Example, Copper, Brass, Mild steel, etc.

- With an increase of grain size or abrasive particle size, the material removal rate is increasing first and then decreasing.

- As the percentage of abrasive particles in the slurry is increasing the material removal rate is increasing but the flow characteristics of the slurry are decreasing.

- Therefore the optimum percentage of abrasives in the slurry is 40-60%.

- Wear ratio mainly depends on the brittleness of workpiece material i.e. the higher the brittleness, it is easy to produce the brittle fracturing. Hence, the wear ratio becomes higher.

Advantages of Ultrasonic Machining Process (USM):

- Highly brittle materials can be easily machineable.

- Circular, non-circular of very small size is <1mm size can be produced by using this USM method.

- Out of all the non-traditional machining methods, ultrasonic machining requires lower specific cutting energy.

- No electrical conductivity of the workpiece is required.

- No thermal effects on the workpiece are required.

Disadvantages of Ultrasonic Machining Process (USM):

- Only brittle materials can be machinable.

- A deeper hole is not possible to produce i.e. L/D ratio up to 3 only is produced.

- Because of brittle fracturing, the surface finish produced is poor.

- Because of impact loads are acting on to the workpiece, the internal residual stresses may be generated in the workpiece.

Applications of Ultrasonic Machining Process (USM):

- This ultrasonic machining method is mainly used for producing circular,non-circular holes in the highly brittle materials like glass, ceramics, etc.

- The dentist uses ultrasonic machining for producing the holes in the human teeth.

References:

- Machining, Machining Operations & Types of Machining Tools

- Ultrasonic Machining - NIT Calicut