Radial Drilling Machine: Definition, Diagram, Parts, Working, Advantages, Disadvantages, and Applications [PDF]

Drilling Machine is used to make circular holes on the components with the help of Drill bits. In the last article, we had discussed the Drilling Machine, Surface Grinding Machine, Milling Machine, lathe machine, etc. whereas, in Today's article, we are going to discuss Radial Drilling Machine along with its Definition, Diagram, Parts, Working, Advantages, Disadvantages, and Applications.

Radial Drilling Machine Definition:

Radial Drilling Machine is used to drill the holes in the given radial distance when the component size is larger in terms of height with respect to the work table.

When the component is large, it cannot fit its structure in the Machine vice. Therefore, the component has to be placed on the ground and the Radial arm of the drilling machine has to be rotated with respect to the component to do the operation.

The Angle of a Drill bit is 118 Degrees.

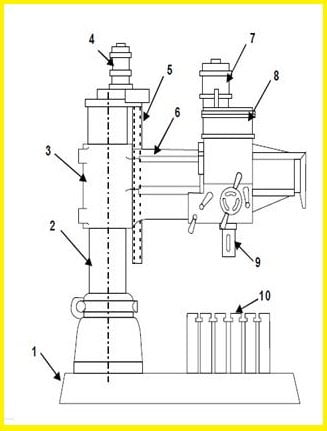

Line Diagram of Radial Drilling Machine:

The line diagram of the Radial Drilling machine is shown below.

Parts of Radial Drilling Machine:

The Parts of the Radial Drilling Machine are as follows.

- Base

- Column

- Radial Arm

- Motor for elevating the arm

- Elevating screw

- Guideways

- Motor for driving drill spindle

- Drill head

- Drill spindle

- Table

An explanation for the Parts of Radial Drilling Machine:

The explanation for the parts of Radial Drilling Machine are as follows.

Base:

It is made up of Cast Iron which possesses high compressive strength and good wear resistance. The base is used to support the assembly of parts on it and also absorbs the vibrations induced by the machine parts.

Column:

It is exactly placed at one end of a bed which can act as a support for rotating the radial arm in 360 degrees.

Radial Arm:

It is the arm that is connected to the Column. The Drill head is a slide from one end to another end by the guideways.

Motor:

It is placed on the drill head for driving the work unit (Spindle of the Drillbit).

Table:

The machine vice is connected to a swivel table that can hold the workpiece for further operation.

Flywheel or Hand Wheel:

It is connected to the spindle arrangement which is used to move up and down with respect to the workpiece.

Drive Head:

It generally consists of two levers which by varying can increase or decrease the speed of chuck.

Chuck:

One end of the chuck is connected to the spindle arrangement and another end is connected to the drill bit (tool).

Drill Bit:

The drill bit act as a tool for drill the holes on the specimens.

Workpiece:

If the workpiece is small then it can be placed on the swivel table else it can be placed on the ground such that radial arm is used for drilling purposes.

Working Principle of Radial Drilling Machine:

When the power supply is given, the spindle rotates which was in conjunction with the motor. The Radial arm is adjusted w.r.t the type of operation and height of the workpiece. The spindle is connected to the chuck and the drill bit is placed in between the jaws of the chuck.

The Drill head is adjusted on to the workpiece and a suitable feed is given. Then the drill bit drives into the workpiece very easily.

Drive Mechanism [Rack and Pinion Mechanism]:

When the hand wheel is rotated, then the Pinion which is attached to the rack also rotates which can convert the rotary motion to the linear motion and the driving mechanism is called as Rack and Pinion mechanism.

Advantages of Radial Drilling Machine:

The Advantages of Radial Drilling Machine are as follows.

- Radial Drilling Machine is advanced compared to the Bench Drilling machine.

- With the help of its radial arm, it can able to drill holes on the components which are larger than the space between the drill bit and the worktable.

- Works efficiently on different metals and wood materials too.

- The worktable can be rotated through 360 degrees.

- It exhibits High Precision and Accuracy.

Disadvantages of Radial Drilling Machine:

The disadvantages of Radial Drilling Machine are as follows.

- They are large machines and take up a lot of real estate.

- It has been designed for medium to large workpieces.

Applications of Radial Drilling Machine:

The applications of Radial Drilling Machine are as follows.

- They are used in industries for the massive production of components.

- They are used in Educational Institutions for performing lab experiments.

- They are used in Small scale and Large Scale Industries too.

FAQs on Radial Drilling Machines:

What are the advantages of radial drilling machine?

What do you Mean by Radial Drilling Machine?

This is the detailed explanation of Radial Drilling Machine. If you have any doubts, you can ask us and we will be replying you as soon as possible.

More Resources:

Drilling Machine

Parts of Lathe Machine and their function

Machining Process

Reference Links [External Links]:

- Selection of Machining parameters on Radial Drilling Machine