Category: Manufacturing Process

LATEST ARTICLES

Shaper Machine: Definition, Parts, Working Principle, Types, Operations, Specifications, Applications, Advantages, and Disadvantages [PDF]

Hello Readers, In today's article we will discuss the Shaper Machine in brief along with its Definition, Parts, Types, Working Principle, Operations, Specifications, Applications, Advantages, and Disadvantages. So let's get started. Definition of Shaper Machine: Shaper Machine is used to remove the material from the surface of the workpiece by the usage of reciprocating single-point […]

Difference between Shaper and Planer Machine [PDF]

In the last session, we had discussed various conventional machines such as Drilling machines, radial drilling machines, milling machines, lathe machines, etc. whereas, in today's article, we are going to discuss the Difference between Shaper and Planer machine in a detailed way. But before that let's see the definition of both Shaper machine and Planer […]

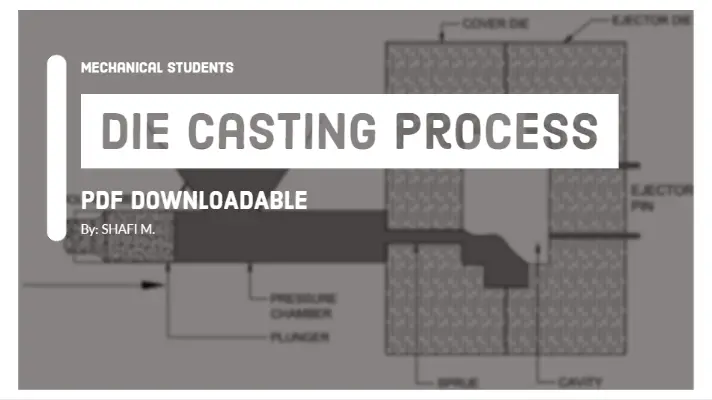

Die Casting Process: Definition, Components, Types, Working Principle, Advantages, Disadvantages, and Applications [PDF]

Die Casting Process is different from the Sand casting process with respect to the mold only. In Sand Casting Process, the mould is made up of Sand whereas, in this process, the mold is made up of Metal. Most die castings are made from non-ferrous metals specifically aluminium, zinc, lead, copper pewter, and tin-based alloys. […]

NC Machine: Definition, Types, Components, Working, Applications, Advantages, Disadvantages, and Differences [PDF]

In the last session, we had discussed conventional machines like Drilling machine, Milling Machine, Grinding Machine, lathe machine, etc. Whereas in today's session, we will discuss briefly on NC Machine along with its Definition, Types, Components, Working, Applications, Advantages, Disadvantages, and Differences. Let's see the definition of it... Definition of NC Machine: If each axis […]

Radial Drilling Machine: Definition, Diagram, Parts, Working, Advantages, Disadvantages, and Applications [PDF]

Drilling Machine is used to make circular holes on the components with the help of Drill bits. In the last article, we had discussed the Drilling Machine, Surface Grinding Machine, Milling Machine, lathe machine, etc. whereas, in Today's article, we are going to discuss Radial Drilling Machine along with its Definition, Diagram, Parts, Working, Advantages, […]

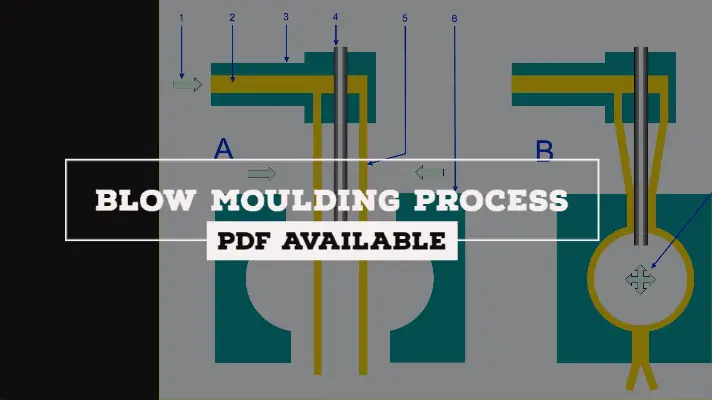

Blow Moulding Process: Parts, Working Principle, Defects, Advantages, Disadvantages & Applications [PDF]

Blow Moulding is a manufacturing process by which hollow plastic products can be obtained. It is also used for forming plastic containers, plastic buckets, bottles, or other hollow shapes. It is applicable for thermoplastics only. We already had an article on the Injection Moulding Process, and Compression Moulding whereas, in today's paper, we are going […]

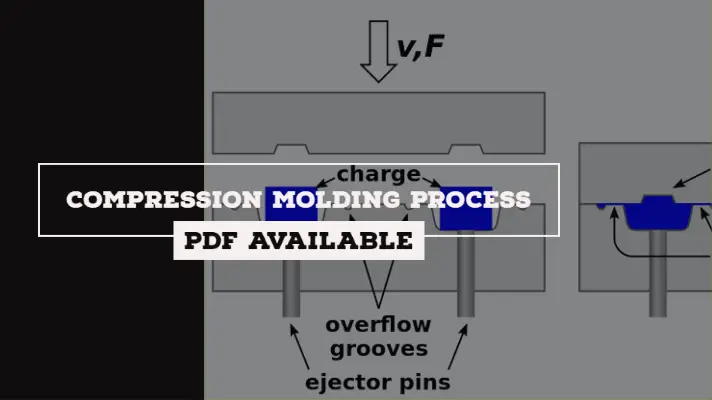

Compression Molding Process: Working Principle, Advantages, Disadvantages, Applications & Defects [Notes with PDF]

Hello readers, in this paper we will be going to give you a detailed explanation of the Compression Molding Process along with its Working Principle, Advantages, Disadvantages, Applications and, Defects is presented below. What is Compression Molding Process? Compression Molding is a molding method in which the molding material(especially Thermoplastics or Thermoset plastics) is generally […]

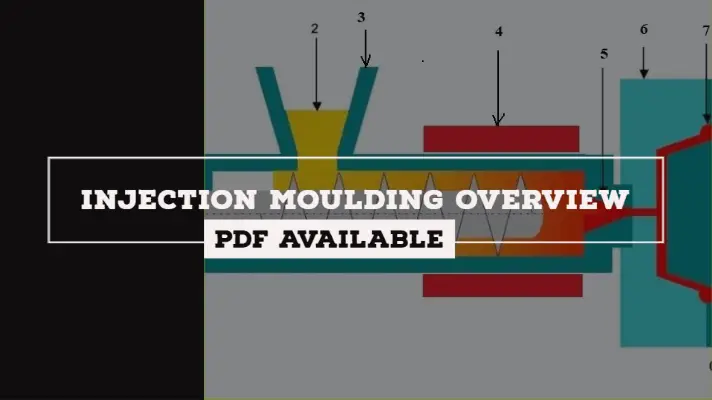

Injection Moulding Process: Definition, Parts, Working Principle, Defects, Advantages, Disadvantages & Applications [PDF]

The Injection Moulding Process is a manufacturing process used for producing parts or components by injecting molten material into the mold cavity. Injection molding can be performed with only one of these materials like glass, plastics, etc. and most commonly, thermoplastic polymers are used. Note: It is applicable to thermoplastic materials only. The Injection Moulding […]

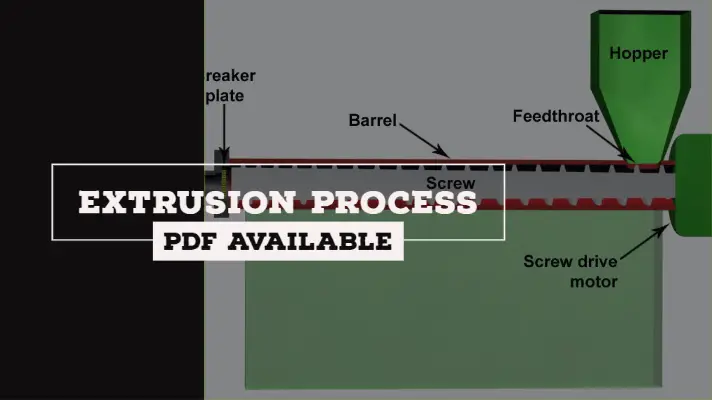

Extrusion Process: Definition, Types, Advantages, Disadvantages & Applications [PDF]

The extrusion process is widely used in the production of hollow pipes and tubes. In this article, we are going to discuss the Extrusion Process along with its Definition, Types, Advantages, Disadvantages & Applications in a detailed way. Definition of Extrusion Process: Extrusion is a compression process in which the work material is forced to […]

Rolling Process: Definition, Working, Rolling Mills, Advantages, Disadvantages & Applications [PDF]

Rolling is a metal forming process in which the deformation takes place under the application of Compressive forces between the rollers. In this article, we are going to discuss a detailed presentation on the Rolling Process with its Principle, Working, Types of Rolling Mills, Advantages, Disadvantages & Applications. Let's dive into the article of Rolling […]