Category: Manufacturing Process

LATEST ARTICLES

Electrical Discharge Machining (EDM): Parts, Working Principle, Advantages, Disadvantages & Applications [PDF]

Electrical Discharge Machining is also known as Spark Machining or Spark Eroding process. As you know that there are various Non-traditional machining methods and EDM is one of them and the rest are presented below. Ultrasonic Machining Process Electrochemical Machining Process Water Jet Machining Abrasive Water Jet Machining Electron Beam Machining Process Laser Beam Machining […]

Drilling Machine: Definition, Types, Parts, Working Principle, Operations, Advantages, Disadvantages, Applications [PDF]

In the last class, we had discussed the Milling Machine and its operations in a detailed way whereas, in today's article, we will discuss the concepts of Drilling Machining along with its parts, working principle advantages, disadvantages, and applications. Drilling Machine: It is a machine which is used to drill the holes on the components […]

Electrochemical Machining (ECM): Introduction, Diagram, Parts, Working, Advantages, Disadvantages, Applications [PDF]

Electrochemical Machining process, the combination of electrical energy and chemical energy makes the removal of material from the surface of a work-piece. It works on the principle of Faraday's law of electrolysis. Before dive into the main topic let me give you some idea related to ECM. Principle-Faraday's law of electrolysis: The mass of a […]

Machining Process: Definition, Types, Advantages, Disadvantages & Applications [PDF]

Hello learners, today in this paper we are going to discuss What is Machining Process? and also see the types, advantages, disadvantages and applications of the Machining Process. Before going down to the machining process, we need to know about some terms, and they are as follows. Machine Tool Definition: A machine tool is a […]

Forging Process: Definition, Types, Diagram, Advantages, Disadvantages, and Applications [PDF]

Forging Process is a metal forming process in which the forces are applied on the material such that the stresses induced in the material are greater than the yield stress and less than the ultimate stress so that the plastic deformation produced in the material will be used for changing the shape of the component […]

Brazing and Soldering Process: Working, Advantages, Disadvantages & Applications [PDF]

In all the non-fusion welding processes, when the liquid molten metal is poured at the joint, it gets wet and Solidifies. During the process of Solidification, the atoms present on the surface of the filler rod are sharing the energy with atoms present on the surface of parent material, and thereby it produces the joint. When the surface […]

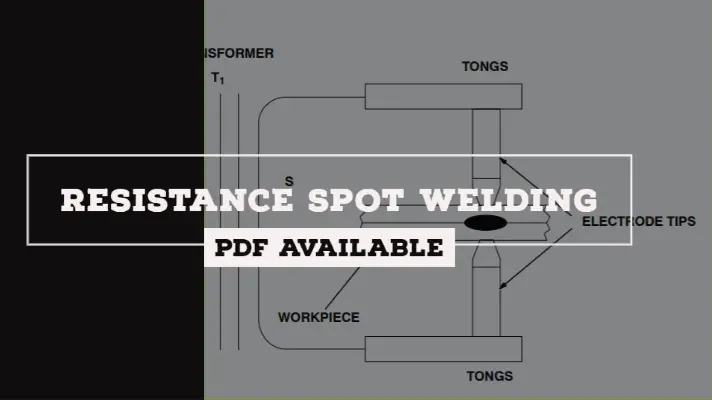

Resistance Spot Welding: Definition, Construction, Working Principle, Applications, Defects, Advantages, and Disadvantages [PDF]

Resistance Spot Welding Operation is used for joining the plates of railway tracks, fuel tanks, domestic radiators, etc. In the last session, we had discussed the gas welding process and arc welding process and whereas in today's session, we will discuss Resistance Spot Welding along with its Definition, Construction, Working Principle, Applications, Defects, Advantages, and […]

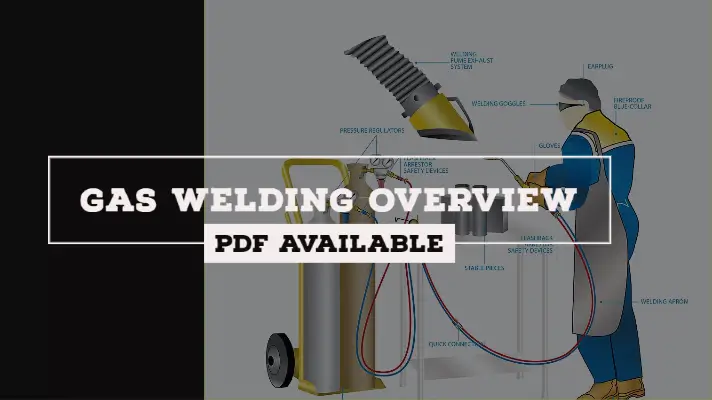

Gas Welding Process: Definition, Equipment, Working Principle, Types of Flames, Advantages, Disadvantages & Applications [PDF]

To speak simple, Gas welding is a process of joining two metals with the application of heat from the flames so that they will melt and join together. In the last session, we had discussed Electric Arc Welding process along with Arc Recovery Time and Arc Characteristics whereas, in today's session, we can discuss Gas […]

Casting: Definition, Types, Steps involved in casting, Advantages, Disadvantages, Importance [PDF]

Definition of Casting: Casting is a process in which the liquid molten metal is poured into the casting cavity whose shape is same as that of the shape of the casting to be produced, allowing to solidify and after solidification, the casting will be taken out by breaking the mould called as Casting Process. Types […]

Sand Casting Process: Definition, Terminology, Explanation, Advantages, Disadvantages & Applications [PDF]

The sand casting process is used for the creation of cylinder blocks, machine tool beds, pistons, etc. where you can produce the components in bulk which is not possible by means of the machining process. All the beds of machines are large enough and cannot be prepared on any machine. Therefore, those products will be […]