Electromagnetic Clutch: Components, Working Principle, Advantages, Disadvantages, Applications [PDF]

Electromagnetic clutch works with the help of electrical winding embedded in the flywheel. The engagement and disengagement of the clutch can be done by ionizing and deionizing the winding placed in the flywheel.

As we know that we have different types of Friction clutches and Electromagnetic clutch is one of the types of clutches. The remaining are:

- Cone Clutch

- Single Plate Clutch

- Centrifugal Clutch

The explanation of Electromagnetic Clutch is as follows.

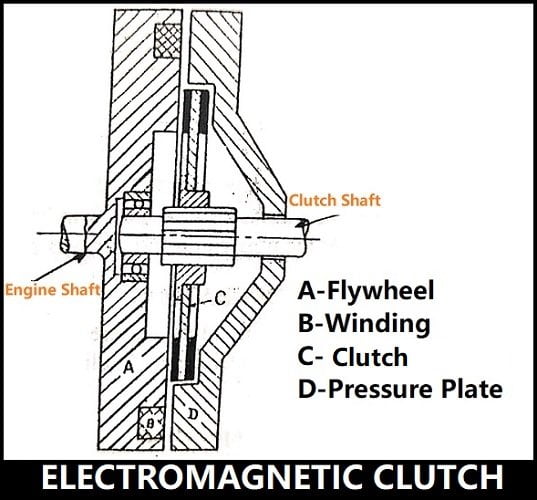

Line Diagram of Electromagnetic Clutch:

Components of Electromagnetic Clutch:

The components of Electromagnetic clutch is as follows:

- Flywheel (represented in fig. with A)

- Winding ( represented in fig. with B)

- Clutch Plate ( represented in fig. with C)

- Pressure Plate ( represented in fig. with D)

Flywheel:

It is connected to the engine shaft to transmit the power to the clutch shaft.

Winding:

It is Ionized with the help of current taken from the dynamo of battery. When the winding is ionized, it attracts the pressure plate D towards it and thereby the clutch is in engaged position.

Clutch Plate:

It is placed in between the flywheel and the pressure plate. It acts as a mode of transmission for the engagement and disengagement of power.

Pressure Plate:

While engagement, the pressure plate presses the clutch plate into the flywheel to transmit the power.

Working of Electromagnetic Clutch:

For working of electromagnetic clutch, it essentially requires four parts. They are Engine Flywheel, winding, Clutch Plate and Pressure plate. The explanation of all the parts is as follows.

The engine flywheel is represented with A and the winding B is incorporated in the flywheel.

The winding B is supplied with current from the dynamo of battery.

The clutch shaft has splines and the clutch plate C is lined with friction surfaces and is free to slide on it.

The pressure plate is represented by D which is used to press the clutch plate w.r.t. the flywheel.

When the winding B is energized, it will attract the pressure plate D, thereby clutch is under engaging position.

When the supply to winding B is cut off, the clutch is disengaged. Every time the clutch can be disengaged by the driver to change the gear and this can be done by pressing the release switch on the Gear lever.

At lower engine speeds, the output of dynamo is also low which makes less force in winding.

For that, three springs are provided in the clutch (not shown in the figure) in order to balance the reduction of electromagnetic force at low speeds.

Due to this, sufficient amount of power will be sent to the winding to ionize and thus disengaging of the clutch takes place.

During normal operation, the electromagnetic force of the winding is regulated by means of an electrical resistance.

This electrical resistance is controlled by means of accelerator pedal.

The resistance is gradually cut, as the acceleration pedal is pressed. Due to this, there is an increase in the electromagnetic force.

Advantages of Electromagnetic Clutch:

Here are some advantages of Electromagnetic Clutch:

- It can be installed in any remote location because, no linkage is required to operate the clutch.

- Easy to operate.

- At contact point, there is less wear and tear

- It can be used to achieve automatic transmission.

Disadvantages of Electromagnetic Clutch:

And these are some disadvantages of Electromagnetic Clutch:

- Higher initial cost.

- Since the clutch operating temperature is limited, the major disadvantage arises is the heat capacity.

Applications of Electromagnetic Clutch:

Electromagnetic Clutch used in different areas like:

- This type of clutch has been employed in some of the Renault cars.

- It is also used in copy machines, lawnmowers and conveyor drives.

- Apart from above, it is also used in printing machinery, food processing machinery, packaging machinery and factory automation.

Resources:

Cone Clutch

Electronic Ignition System

References [External Links]:

- Wikipedia

- Clutch Knowledge | EXEDY After Market

Media Credits:

- Image 1: By Oguraclutch - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=6972084

- Feature Image: Modified by author

- Video by: oguraindustrial