Classification of Machine Tools [PDF]

Heyllo readers, today I am going to discuss about the Classification of Machine Tools.

Machine tools are those machines that make machines and products for industrial purposes.

The intention of the modern industry is to create a number of useful products in the minimum time, to achieve that purpose we should be careful about choosing the machine tools which can be performed the machining.

Note: Download Purpose and Types of Machine Tools PDF at the end of the article.

A machine tool can be consist of several components, may or may not like:

- A motor

- Power Transmission System

- Workpiece

- Cutting tool

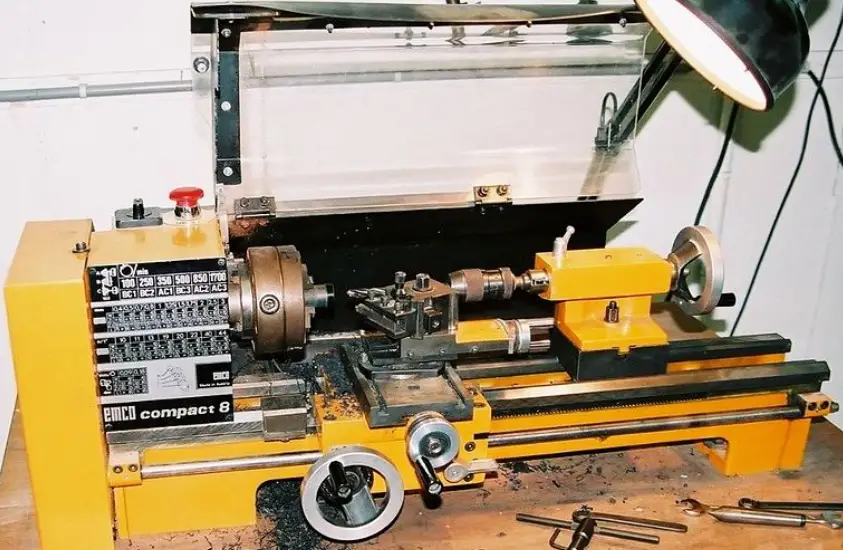

Lathe, Drilling, Milling, etc. are the examples of machine tools which we generally used in workshops around the globe.

Purpose of Machine Tools:

Now let me discuss the purpose of machine tools, why we chose Machine Tools over Hand Tools.

- The main purpose of a machine tool is to remove material from a particular job or workpiece to achieve the desired shape and size.

It can also do by hand tool but here are some advantages of Machine tool over hand tool.

- Firstly we can get a greater accuracy along with efficiency on Machine tools

- Secondly, the machine tool can handle small, medium, as well as large jobs, but in the case of hand tools, you can use it only for small and light jobs.

- In hand tool, the machining time is more, but in the machine tool, the machine time is reduced by 70%

- The machine tool can be used to hold and support the job in a proper position on a table.

- It also holds the tool and tool post

- It is used to give the desired feed, speed, and depth of cut.

- Machine toll give the desired two relative movements on the tool or on the job or one in job and another in tool depending on the machine tool and which operation you are performing.

So these are some of the purposes of Machine Tool.

Now, let's dive into the classification of the machine tools.

Types of Machine Tool:

Machine Tools are broadly classified into three groups, and those are:

- General Purpose Machine Tools

- Single Purpose Machine Tools

- Special purpose machine Tools

Let me discuss one by one,

1. General Purpose Machine Tools:

General-purpose machine tools are designed to perform a great variety of machining operations with a variety of workpieces.

For this type of Machine, tools need some attachments, like in case of lathe we use a mandrel, in milling we use indexing head, like these.

The name comes in this category of machine tools are a lathe, drilling, milling, shaping, etc.

2. Single Purpose Machine Tools:

As the name denotes "single purpose" that means this type of machine tool is designed to perform a single operation but it can machine a number of the workpiece.

This type of machine tool are generally suitable for productive works.

These are the some operation that fell into this category,

- Making of Crank Shaft

- Machining of Crank-pins

- Machining of gear by gear hobbing process

3. Special Purpose Machine Tools:

The special-purpose machine tool is used for performing a particular operation. These types of machine tools are manufactured individually.

We can use these types of machine tools in large production where the production rate is quite higher, although we can use it for mass production too.

Summary:

As we saw, we can categorize machine tools in three broad categories, but in recent days due to the development of machine tools are quite high.

Now with the help of a computer, it can produce any kind of products in any shape, you can take the example of CNC (Computer Numerical Control).

As in the CNC machine, we just need to design the product within the system and it can develop that product within some hour or minutes, and also it can develop some complex shapes that do not even produce by those conventional machine tools.

So this is the end of the discussion on Classification of Machine Tools, I hope I was able to spread my knowledge. Feel free to ask any question in the comment section, I love to answer those. Cheers.

References [External Links]:

- https://www.sciencedirect.com/science/article/pii/S2212827114001528

- Machine tool | Description, History, Types, & Facts | Britannica