Single Plate Clutch: Components, Working Principle, Advantages, Disadvantages, and Applications [PDF]

In the single-plate clutch, a friction plate (clutch plate) is held in between flywheel and the pressure plate.

The Single plate clutch is used to transmit a small amount of power compared to the multi-plate clutch. The single-plate clutch is used in trucks, cars, buses, etc.

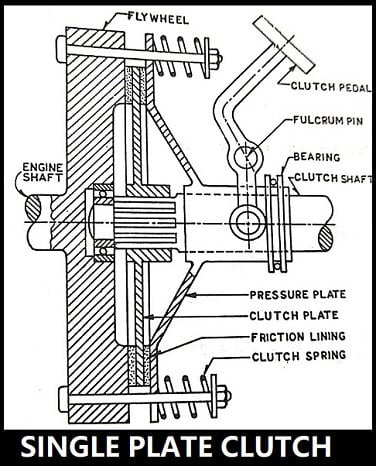

Line Diagram of Single Plate Clutch:

The line diagram of Single Plate Clutch is as follows:

Components of Single Plate Clutch:

The components of Single Plate Clutch are as follows.

- Flywheel

- Engine shaft

- Clutch shaft

- Bearing

- Clutch Plate

- Clutch Pedal.

- Friction Lining

- Pressure Plate

- Clutch spring

Explanation for the Components of Single Plate Clutch:

Flywheel:

It is connected at the end of the engine shaft and can rotate along with the shaft to transmit the power to other parts when the clutch is in the engaged position.

Engine Shaft:

From Engine shaft, the power is transmitted to the gear box via clutch plate.

Clutch Shaft:

This is used to hold the clutch plate and thereby engaging with the flywheel to transmit the power.

Bearing:

The bearing rides on the clutch spring for proper engagement and disengagement.

Clutch Plate:

Here in the single-plate clutch, only one friction plate or clutch plate is used to transmit the power when there is an engagement.

The clutch plate is mounted on a hub which is splined from inside and is thus free to slide over the gearbox shaft.

Clutch Pedal:

When you need to change the gear then you need to disengage the clutch and that can be possible only with clutch pedal.

When the driver is applying force on the pedal, it means that he is disengaging the clutch plate to change the gear and if the driver releases the pressure from the clutch pedal, it means that the clutch plate is engaged and the power is transmitted to the gearbox.

Friction Lining:

Friction Lining is to be placed on the inside surface of flywheel and the outer surface of clutch plate for the better engagement without the formation of slip.

Friction facing is attached on both sides of the friction plate to provide annular friction surfaces for the transmission.

Pressure Plate:

It is responsible to fix the clutch plate with the flywheel as a support when there is an engagement among them and it is also responsible for disengagement of clutch.

Clutch Spring:

To keep the clutch in engaged position, the springs are arranged circumferentially around the shaft which provide axial force for proper engagement.

Working of Single Plate Clutch:

The working of Single Plate Clutch can be explained by means of Disengagement and Engagement of Clutch.

Disengagement of Clutch:

When there is an application of pressure on the clutch pedal by the driver, the pressure plate is moved towards the right against the spring force and this is achieved by means of thrust bearing and suitable linkages which was not present in the figure. The friction plate or the clutch plate is disengaged with the movement of the pressure plate.

Engagement of Clutch:

When the pressure from the clutch pedal is released, the clutch plate is said to be in engaged position and on the other hand this can be achieved by the pressure plate which is moved towards the left in the direction of spring force such that all these forces can help engaging the clutch for the transmission of power.

Advantages of Single Plate Clutch:

These are some advantages of Single Plate Clutch:

- The gear changing is easier in the single plate clutch compared to the cone clutch because the pedal movement is less in this case.

- Compared with the cone clutch, there is no possibility of binding or joining of cones in the case of single plate clutch and hence it is more reliable.

Disadvantage of Single Plate Clutch:

Here are some disadvantages of Single Plate Clutch:

As compared to cone clutch, the springs have to be more stiff and it means that the driver has to apply the greater force while disengaging.

Applications of Single Plate Clutch:

The single plate clutch is used in the following things:

- Cars

- Trucks

- Buses etc.

Resources:

Cone Clutch

Electromagnetic Clutch

References [External Links]:

Media Credits:

- Feature Image: Modified by Author