Petrol Injection System: Types, Advantages, Disadvantages [PDF]

Petrol Injection was come into the picture because of the drawbacks of the carburetor. It is difficult for a single carburetor to ensure uniformity of mixture to all the cylinders in a Multi-cylinder engine.

By this, some cylinders may get a weaker mixture whereas the other cylinders get a richer mixture then the desired. Due to this, there is an effect of pollution due to the incomplete combustion of mixture in the cylinder. The solution to these troubles has been found by the usage of Petrol Injection.

Types of Petrol Injection System:

- According to the location of Injector

- Direct Injection

- Port Injection

- Throttle body Inspection

- According to Duration and Timing of Fuel Injection

- Continuous Type

- Intermittent Type

- Sequential Type

- According to number of Injectors

- Single Point Injection

- Multi-Point Injection

- According to the control Method

- Mechanical Petrol Injection Method

- Electronic Petrol Injection Method

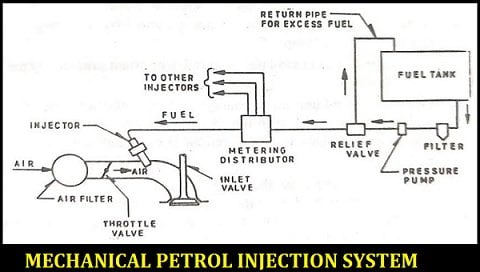

Mechanical Petrol Injection:

This type of injection is operated Mechanically with the help of a Pump, distributor, etc.The Mechanical Petrol Injection pump is obsolete now and it is been replaced by Electronic Petrol Injection Pump so that a higher accuracy is maintained w.r.t. the fuel during the firing order.

Components of Mechanical Petrol Injection System:

A Petrol Injection System consists of the following parts:

- Fuel Tank

- Fuel Filter

- Pressure Pump

- Relief Valve

- Return Pipe for Excess fuel

- Distributor

- Injector

- Air Filter

- Throttle Valve

- Engine Cylinder

Working Principle of Mechanical Petrol Injection:

The above components are explained below under working section and are bolded for you so that you can understand it in a easier way.

The fuel is to be stored in the fuel tank to supply it into the combustion chamber along with the air. The Fuel filter is used to remove the impurities present in the fuel to avoid the disturbance during the flow.

The Pressure pump is used to check the pressure of the fuel coming from the fuel tank. It pumps the fuel at a specified pressure (about 700 kPa) into a metering distributor.

Relief valve sends the necessary amount of fuel to the distributor and the remaining(excess fuel) will be sent back to the fuel tank with the help of return pipe at constant pressure.

The metering distributor supplies fuel to each injector in turn. The quantity of fuel delivered is also controlled in the distributor by engine manifold pressure.

The injector is ordinarily held closed by spring until the fuel pressure opens it to deliver an atomized spray of fuel. Manual control on the dashboard controls the metering distributor and thereby the quantity of fuel delivered by it.

The Throttle valve opens for the air intake into the cylinder along with fuel into the engine cylinder for proper air fuel mixture.

In this way, by the use of Mechanical Petrol Injection, the fuel is supplied to the engine cylinder via injector.

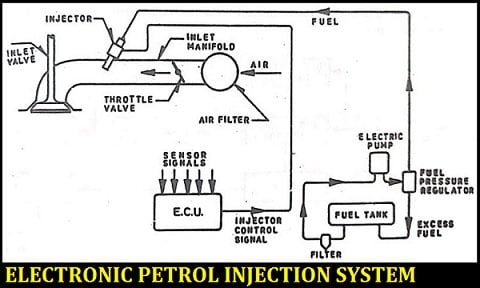

Electronic Petrol Injection:

In the mechanical injection system, there are some limitations, but in the case of the Electronic Petrol Injection system, we can overcome that. By the use of Sensors, and Electronic Unit we can easily control functions like engine speed, temperature, engine load, torque and much more.

In the year 1957, the first commercial Electronic Injection system comes into action and which is developed by Bendix and was proposed by American Motors Corporation

Components of Electronic Petrol Injection:

An Electronic Petrol Injection system is consist of the following parts:

- Fuel Tank

- Fuel Filter

- Electric Pump

- Fuel Pressure Regulator

- Injector

- Electronic Control Unit(E.C.U)

- Air Filter

- Throttle Valve

- Engine Cylinder

Working Principle of Electronic Petrol Injection:

The fuel is to be stored in the fuel tank to supply it into the combustion chamber. The Fuel filter is used to remove the impurities present in the fuel to avoid the disturbance during the flow.

An electrically driven Fuel Pump(S.U.Electrical Fuel Pump) draws the fuel from the tank through a filter and supplies the same to the injectors at a pressure which is held constant using a Fuel-Pressure regulator.

The pump draws more fuel than the required and the excess fuel is returned to the tank by the fuel pressure regulator. In this way, a vapor lock is prevented in the fuel lines.

The injectors are held closed using spring and are opened using solenoids energized by the control signal from the electronic control unit (ECU), which consists of a small pre-programmed analog computer that translates sensor signals into command signals.

The strength of the ECU control signal, which determines the open time of the injector to control the amount of fuel injected, depends upon the engine requirements which are determined by the ECU from the sensor signals from critical locations.

In this way, the ECU works properly to supply an accurate amount of fuel to the injector with respect to air which is drawn into the combustion chamber.

Advantages of Petrol Injection System:

These are the following advantages of Petrol Injection System:

- Very high-quality fuel distribution is obtained.

- Improvement in volumetric efficiency with the corresponding improvement in power and torque.

- The response of the engine to throttle control is very rapid since the is a very small time lag between throttle movement and injection of the which is now directly injected into each inlet port.

- Multi-point injection does not need time for transportation of fuel in the intake manifold. Moreover, there is no wetting of manifold walls.

- Both the single-point or the multi-point systems are particularly suitable for supercharged engines.

- Fuel Consumption is less.

- Fuel Injection equipment is much more precise in metering injected fuel spray into the intake ports over the operating range of engine speed, load, and temperature.

Disadvantages of Petrol Injection System:

There are some disadvantages of Petrol Injection System, and those are the following:

- The initial cost of fuel Injector is very high.

- The mechanism is much complicated compared to Carburettor because of the presence of complicated and precise fuel injection pump, injection nozzle, and pipelines for each cylinder.

- Huge maintenance is required compared to Carburettor.

- There is more noise, mechanical and hydraulic due to the pumping and metering of the fuel.

This is a detailed explanation of the Petrol Injection System also I mentioned the advantages and disadvantages along with its types including the Mechanical Petrol Injection system and Electronic Petrol Injection system.

If you have any doubts, don't forget to mention in the comment section, I will happy to answer those. And also don't forget to share this article.

Read More on Ignition System

Battery Ignition System

Magneto Ignition System

References:

Media Credits:

- Car Engine: By Vegavairbob at English Wikipedia, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=12013462

- Feature Image: Modified by Author