Lamont Boiler: Definition, Parts, Working, Advantages, Disadvantages & Applications [PDF]

Lamont Boiler is a Water Tube boiler and it is also a high-pressure boiler. Before knowing about any type of boiler, we need to know what actually is a Boiler?

In the last article, we had discussed in detail the types of boilers like

Hello Readers, in this assessment, we will discuss on Lamont Boiler along with its Definition, Parts, Working, Advantages, Disadvantages & Applications. So let's dive in!

Definition of Lamont Boiler:

Lamont boiler is a high-pressure water tube boiler with an internally fired furnace and the circulation is of forced type. An external agency (pump) is used to circulate the water throughout the tubes of the boiler.

It was invented in 1925 by the famous person Walter Douglas La-Mont.

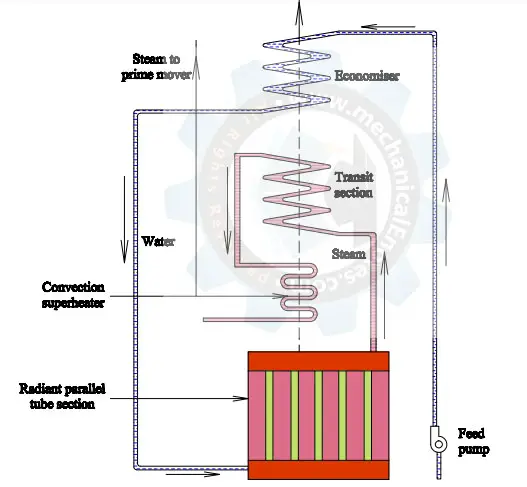

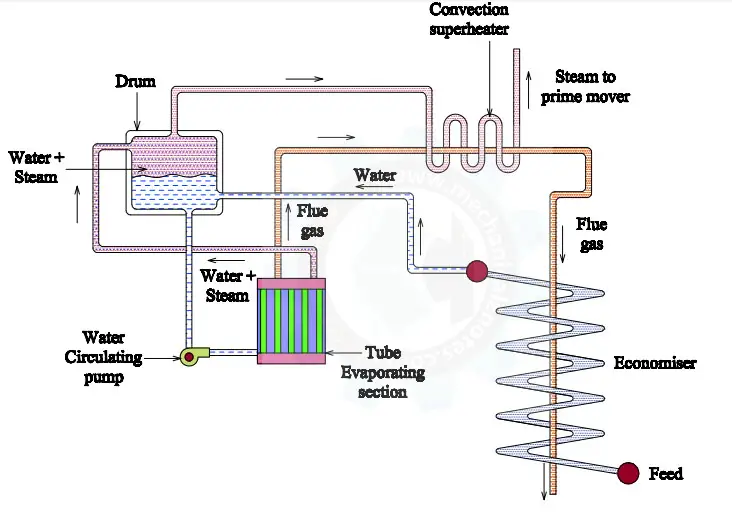

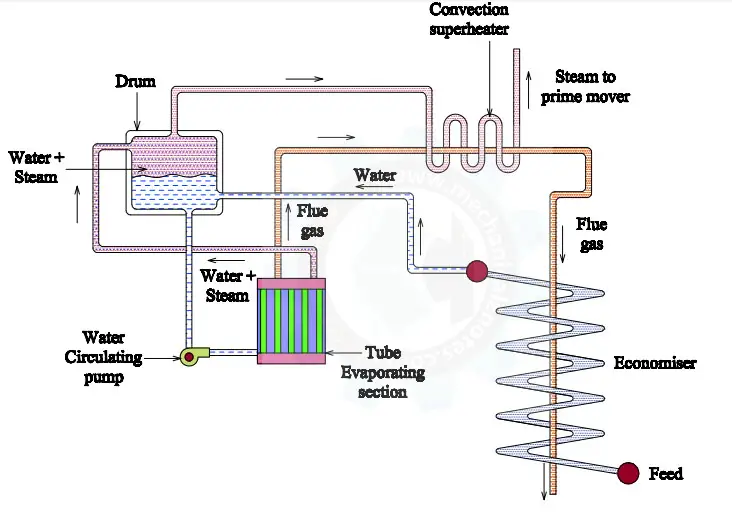

Line Diagram of Lamont Boiler:

The Line Diagram of Lamont Boiler is shown below.

Parts or Construction of Lamont Boiler:

The parts of Lamont boiler are as follows.

- Feed Pump

- Economizer

- Water steam separator drum

- Evaporator Tube

- Water circulating Pump

- Superheater

- Air preheater

An Explanation for the parts is as follows.

Feed Pump:

The feed pump supplies the feed water into the boiler from a hot well.

Economizer:

It is a device which increases the efficiency of the boiler.

Its duty is to preheat the water by the usage of remaining heat from the combustion gases.

Water steam separator drum:

By the usage of this drum, water and steam are separated from each other. Steam due to its less density remains in top position and water due to its high density, settles down.

Evaporator Tube:

The collected water in the drum is to be sent to the evaporating section such that it evaporates water-steam mixture with the help of radiator.

Water Circulating Pump:

Here centrifugal pump is used to supply the water to various channels. Water from the drum is to be passed into the tube evaporating section through the centrifugal pump.

From the evaporating section, a mixture of water and steam is to be sent to the water drum again by the usage of pump.

Water will be settled in the drum and the steam will move further into the superheater.

Superheater:

Even if the steam has small water particles also, the air superheater increases the temperature and finally, the steam enters into the turbine to generate electricity.

Air Preheater:

The remaining hot water from the steam after passing through the superheater acts as a preheated water, mixes with the feedwater, and the cycle continues.

Working Principle of Lamont Boiler:

The feedwater passes through the economizer to the drum from which it is drawn by the circulating pump.

The function of the Economizer is to increases the temperature of the feedwater (preheating) by absorbing the heat from the flue gases before they are sent to the atmosphere.

The centrifugal pump delivers the feed water to the evaporating section or the Radiant Evaporator which in turn sends a mixture of steam and water to the drum.

The steam generated by the radiant evaporator is the saturated steam. If it is directly used in the steam turbine, it can cause the blades by the effect of corrosion.

So the saturated steam sends to the superheater where it can increase the temperature of the steam.

The superheated steam obtained from the superheater is supplied to the prime mover or turbine to do the mechanical work and later this work is to be converted to Electrical energy.

These boilers have been built to generate 45 to 50 tonnes of superheated steam at a pressure of 130 bar and a temperature of 500-degree centigrade.

This is the explanation of how Lamont Boiler work!

Advantages of Lamont Boiler:

The advantages of Lamont boiler are as follows.

• It has a high heat transfer rate.

• Its design is simple.

• It can be easily started.

• High steam generation (about 50 tonnes per hour)

• It can be reassembled with the natural circulation boilers.

Disadvantages of Lamont Boiler:

The disadvantage of Lamont boiler is as follows.

- Bubble formation on a surface of the tube reduces the heat transfer rate.

- The design is not good, and also the fabrication is poor, that's why we can see unnecessary leakage in this boiler.

Lamont Boiler Applications:

The applications of Lamont boiler are as follows.

- These are used in power plants to generate electricity by the usage of turbines.

- They are used in industrial applications.

This is a detailed explanation of Lamont Boiler along with Definition, Parts, Working, Advantages, Disadvantages & Applications. I hope you liked this article, now I want to hear from you.

So don't forget to share your thoughts in the comment section, and do share this article on your favorite social media platform.

Some FAQ's on this Topic:

what are the applications of a boiler?

Is Lamont Boiler is a water tube boiler or fire tube boiler?

At what pressure, Lamont boiler works?

What are the different types of water tube boilers?

Babcock and Wilcox boiler

Stirling Boiler

Benson Boiler

Loeffler boiler, etc.

Which is the main advantage of Lamont boiler?

What is the main disadvantages of Lamont boiler?

More on Boiler:

Babcock and Wilcox Boiler

Cochran Boiler

Benson Boiler

References [External Links]:

- Boiler-Science direct

- Boiler Efficiency - Engineering ToolBox

- Basic Parts of a Boiler | Hunker