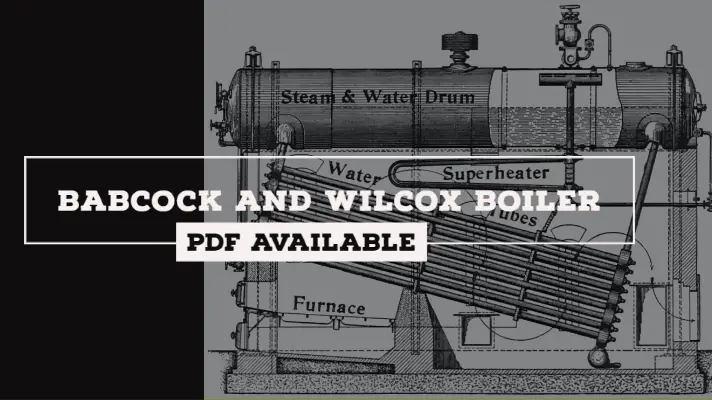

Babcock and Wilcox Boiler: Parts, Working, Advantages, Disadvantages, Specifications, Applications [PDF]

The demand for large size boiler units and Increased pressure led to the introduction of water tube boilers and one of the best design of a water tube boiler is the Babcock and Wilcox Boiler.

Discovery of Babcock and Wilcox Boiler:

The Babcock and Wilcox Boiler was discovered by George Herman Babcock and Stephen Wilcox in the year 1967.

What is Babcock and Wilcox boiler?

This Babcock and Wilcox Boiler is a water tube boiler which is a multi-tubular,high pressure and externally fired water tube boiler used to generate a large amount of steam.

In this article, I will explain all the parts of Babcock and Wilcox Boiler along with working, construction, advantages, disadvantages, specifications and applications.

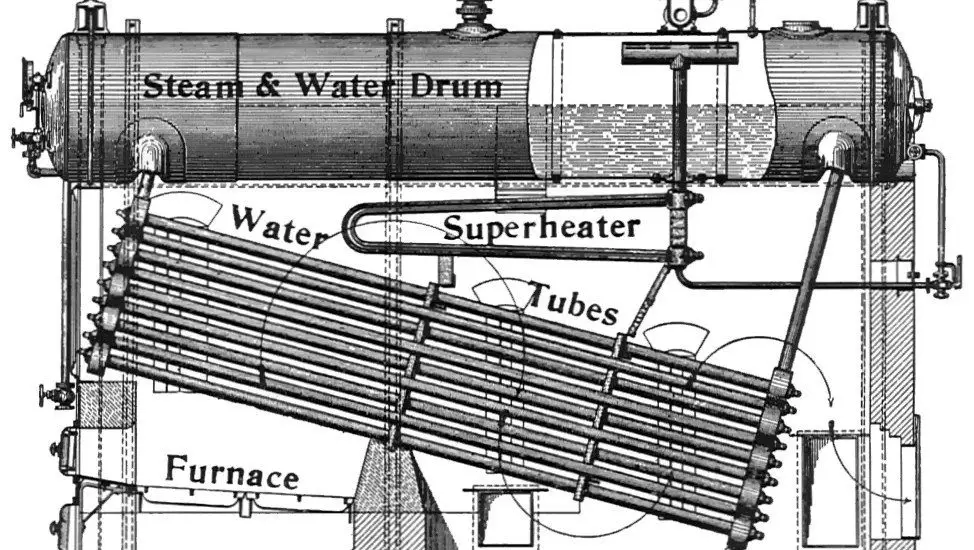

Parts of Babcock and Wilcox Boiler:

The parts of Babcock and Wilcox Boiler is as follows.

- Steam and water drum (boiler shell)

- Uptake-header and Down Take Header

- Water tubes

- Superheater

- Grate

- Furnace

- Baffles

- Mud box

- Inspection doors

- Water space

- Steam Space

- Water Level Indicator

The explanation of the above parts is as follows.

1. Boiler Shell:

It consists of one or more steel plates bent into a cylindrical form and riveted or welded together. The shell and ends are closed with the endplates.

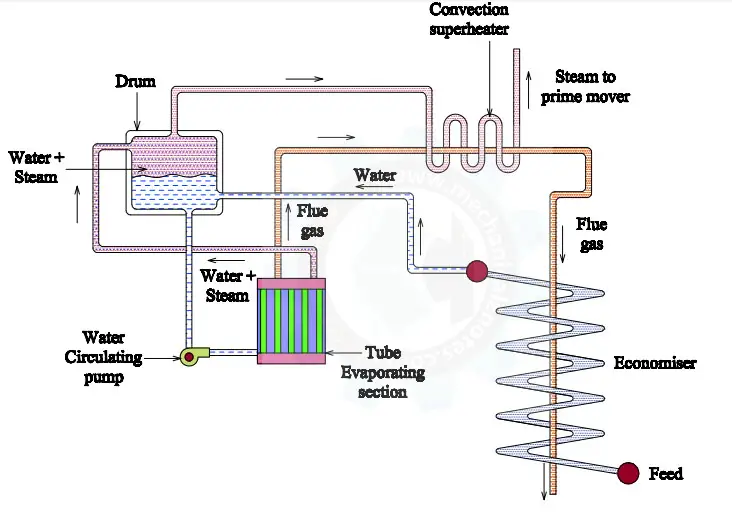

2. Uptake-header and Down Take Header:

Boiler shell and water tubes are connected by the two tubes. Out of them, one is Up Take header and the other is Down Take Header.

- UpTake Header: The steam from the water tubes to the drum flow by means of UpTake Header.

- Down Take Header: The water flows from the drum to the water tubes by means of down take header.

3. Water Tubes:

The angle of inclination of the water tubes to the horizontal is about 15 degrees. In this boiler, water will flow from the drum by means of tubes only.

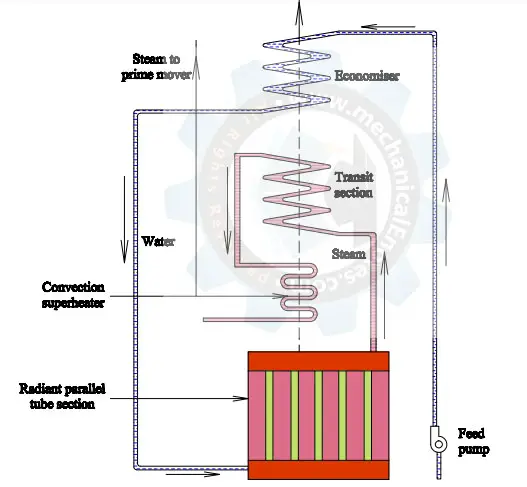

4. Superheater:

It increases the temperature of saturated steam.

5. Grate:

It is the platform in the furnace upon which fuel is burnt.

6. Furnace:

It is a chamber formed by the space above the grate and below the boiler shell in which combustion takes place.

It is also called a firebox.

7. Baffles:

The baffles are provided to deflect the hot flue gases so that the water tubes experience more amount of heat.

8. Mud Box:

All the impurities which are present in the boiler are deposited at the om and are stored in the mud box.

9. Inspection doors:

They are provided for cleaning and inspection of the boiler.

10. Water space:

It is the volume of a shell that is covered by water.

11. Steam Space:

The volume of shell except, the volume of water and tube space is called Steam space.

12. Water Level Indicator:

It is the indicator, which shows the level of water in the shell.

Working of Babcock and Wilcox Boiler:

The Working principle of Babcock and Wilcox Boiler is as follows.

- The entire boiler except for the furnace, are hung by means of metallic slings or straps or wrought iron girders supported on pillars.

- This arrangement enables the drum and the tube to expand or contract freely.

- The angle of inclination of the water tubes to the horizontal is about 15 degrees.

- A feed valve is provided to fill the drum and the inclined tubes with the water level of which is indicated by the water level indicator.

- Through the fire door, the fuel is supplied to the fire grate and it is burnt. The hot gases are forced to move upwards between the tubes by the baffle plates.

- The system consists of a Down Take Header(DTH) and UpTake Header(UTH) which consists of holes in which a series of Inclined water tubes are fixed.

- The water from the drum flows through the inclined tubes via down-take header and goes back into the shell in the form of steam and water mixture via UTH (Up Take Header).

- The steam is collected in the steam space of the drum.

- The steam enters through the APP(Anti-Priming Pipe) and flows in the ST(Superheater Tubes), where it converts from Wet steam to Dry saturated steam and it is taken out from MSV(Main Stop Valve) and feed to the turbine.

- At the lowest point of the boiler, the mud and dirt collect which is pumped out through Blow-off Cock.

Advantages of Babcock and Wilcox Boiler:

The Advantages of Babcock and Wilcox Boiler is as follows.

- Generate Steam at high pressure and rate is high (140 bar and 40000kg/hr)

- For a given output, it occupies less space.

- Parts are accessible for cleaning, inspection, and repair

- Parts can be separated and transported easily.

- Due to the heating surface, Fuel is completely burnt.

Disadvantages of Babcock and Wilcox Boiler:

The disadvantages of Babcock and Wilcox Boiler is as follows.

- Pure feed water required

- Cost is high

Specifications of Babcock and Wilcox Boiler:

The specifications of Babcock and Wilcox Boiler is as follows.

- The diameter of the drum = 1.22 to 1.83 m

- Length = 6.096 to 9.144 m

- Size of the Super-heater tubes = 3.84 to 5.71 cm

- Steaming Capacity = 40000kg/h (max)

- Size of the water tubes are 7.62 to 10.16 cm

- Efficiency = 60% to 80%.

- Working pressure = 140 bar (max)

Applications of Babcock and Wilcox Boiler:

The Applications of Babcock and Wilcox Boiler is as follows.

- In power generation industries, the Babcock and Wilcox Boiler is used to produce high pressure steam.

- The steam generated is used to produce large amount of electricity.

This is the detailed explanation of Babcock and Wilcox Boiler. If you have any doubts, feel free to ask in the comments section.

More Resources:

High-Pressure Boiler

Cochran Boiler

External Links:

- Babcock and Wilcox Boiler-PDF

Media Credits:

Image 1: By Andy Dingley (scanner) - Scan from Prof. William Ripper, Sheffield Univ. d.1937 (1913 edition of 1909 book. Originally published in 1889 as "Steam", but later expanded to cover internal combustion engines and so re-titled.) Heat Engines, London: Longmans, Public Domain, https://commons.wikimedia.org/w/index.php?curid=6896156