Cochran Boiler: Definition, Parts, Working, Specification, Applications, Advantages & Disadvantages

Cochran boiler is efficient than the simple vertical boiler and it was founded by Cochran & Co. of Annan. In this boiler, the fire tubes are placed horizontally and the hot gases are surrounded around them for the generation of steam.

In this article, we will discuss Cochran Boiler: Definition, Parts, Working, Specification, Applications, Advantages & Disadvantages in a detailed way.

Cochran Boiler Definition:

Cochran Boiler is one of the best types of vertical, multi-tubular boiler which has a number of horizontal fire tubes used for the generation of steam.

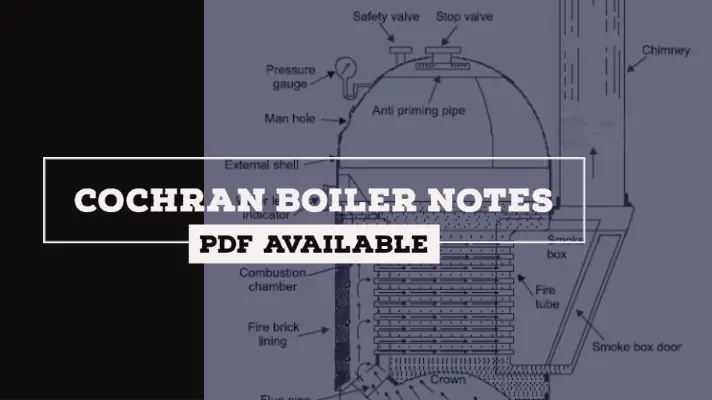

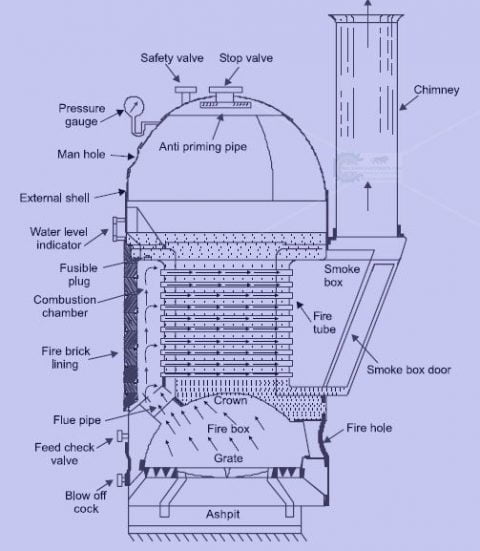

Line Diagram of Cochran Boiler:

The diagram of Cochran Boiler is shown below.

Parts of Cochran Boiler:

All the parts of Cochran Boiler are explained below:

- Shell

- Combustion Chamber

- Grate

- Ash Pit

- Fire hole

- Furnace

- Flue Pipe

- Fire brick Lining

- Fire Tubes

- Chimney

- Manhole

- Smokebox

- Hemispherical Dome

An Explanation for the parts of Cochran Boiler:

The detailed explanation for the parts of Cochran Boiler is as follows.

1.Shell:

It has a cylindrical drum with a hemispherical dome at its top.

2.Combustion Chamber

Burning of fuel takes place in the combustion chamber.

3.Grate

It is the sectioned platform on which the fuel(Coal) is burnt.

4.Ash Pit:

Ash is collected from the burnt fuel placed on the grate which will deposit into the Ash pit.

5.Fire hole:

It is the hole provided to the shell to fire(burn) the fuel.

6.Furnace:

It is the region where combustion takes place and without a furnace, it is not possible to get the steam.

7.Flue Pipe:

The hot gases enter into the combustion chamber through the flue pipe only. It is a small passage that connects the combustion chamber and firebox.

8.Fire Brick Lining:

This helps in the combustion of the fuel. After striking brick lining, the flue gases pass through the horizontal tubes.

9.Fire Tubes:

This boiler has multi-tubular fire tubes. The fire tubes help in the exchange of heat from the hot flue gases to the water surrounded around it. The hot flue gases from the combustion chamber travel to the smokebox through these fire tubes only.

10.Chimney:

The chimney is attached to the smokebox which is used to transfer the flue gases coming from the fire tubes, to the environment.

11.Manhole:

A manhole is provided for inspection and cleaning of the boiler.

12.Smokebox:

It is used to collect the flue gases and unburned fuel coming out from the combustion chamber.

13.Hemispherical Dome:

The steam is deposited in this dome after its generation from water.

Other Boiler mountings and accessories attached to this boiler are:

Pressure Gauge:

It measures the pressure of steam inside the boiler.

Water level Indicator:

The water level in the boiler is indicated by the water level indicator.

Safety Valve:

It blows off the steam when it reaches beyond the safety level inside the boiler.

Blow off Cock:

It is used to blow off the impurities present in the boiler water.

Working Principle of Cochran Boiler:

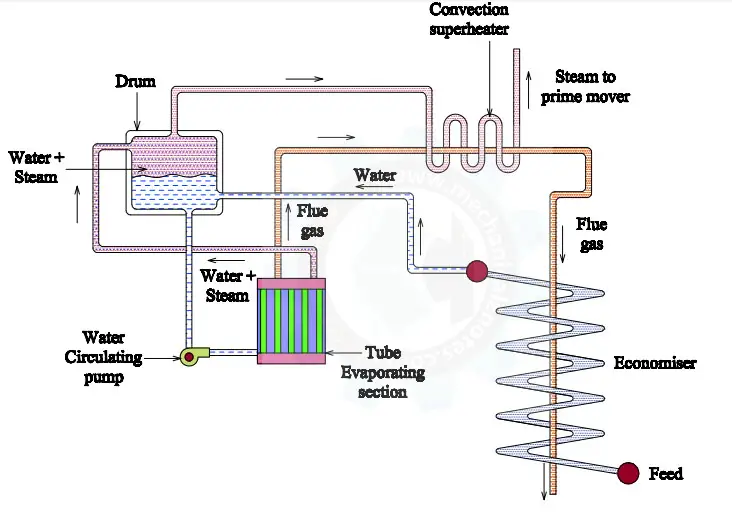

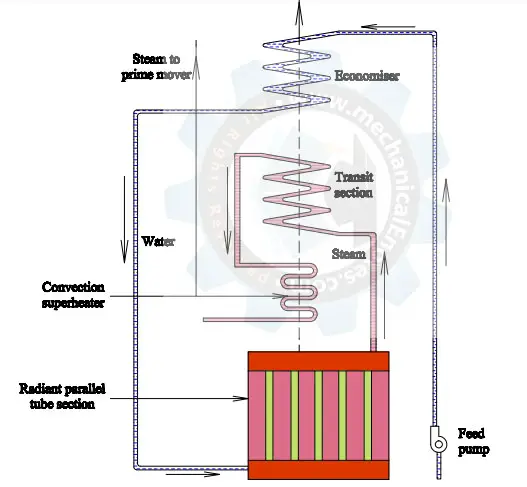

The fuel(coal) is to be placed on the grate and is to be burnt from the fire hole. The air enters into the combustion chamber from the atmosphere.

The fuel is to be burned in the Firebox and the smoke, hot flue gases emerges into the combustion chamber through the flue pipes.

From the combustion chamber, hot gases enter into the fire tubes. As the water is surrounded by the fire tubes, exchange of heat takes place between them.

Due to the hot gases, the water converts into steam and moves upward to the hemispherical dome.

The Anti-priming pipe absorbs the water molecules from the steam collected in the hemispherical dome and makes it as dry steam which can be sent to the turbines to do work through the steam stop valve mounted on the top of the hemisphere.

The burnt gases and smoke is discharged to the atmosphere through the chimney.

The burnt fuel is to be collected into the Ash pit and the impurities which are present in the water will be discharged out through the Blow off cock.

A fusible plug is also provided at top of the combustion chamber. When the temperature of the combustion chamber crosses the permissible level, the fusible plug melts and the water enters into the furnace of the boiler and stop the fire. In this way, we can avoid accidents in the industry.

In this way, the steam is used to drive the turbines.

Specifications of Cochran Boiler:

The dimensions, working pressure, heating surface, capacity and efficiency of the Cochran Boiler are as follows.

- Shell diameter:b2.75m

- Height:5.79m

- Steam Capacity: 3500 kg/hr (maximum capacity

- Tubes diameter: 6cm

- Working Pressure: 6.5 bar (max pressure 15 bar)

- Heating surface: 120 m2

- Efficiency: 70 to 75%

Applications of Cochran Boiler:

The applications of Cochran Boiler are as follows.

- It is used in refining units

- It is used in paper and pulp manufacturing plants.

- It is also useful in chemical processing plants.

Advantages of Cochran Boiler:

The advantages of Cochran Boiler are as follows.

- Low initial installation cost.

- Transportation of the Cochran boiler is easy.

- Easy to operate and handle.

- It requires less floor area.

Disadvantages of Cochran Boiler:

The disadvantages of Cochran Boiler are as follows.

- Low rate of steam generation.

- It has a limited pressure range.

- The installation requires a large area due to its vertical design.

- Inspection and maintenance are difficult.

This is the detailed explanation of Cochran Boiler. If you have any doubts, feel free to ask from the comments section.