Benson Boiler: Definition, Parts, Working, Advantages, Disadvantages & Applications [Notes with PDF]

In the last session, we discussed Lamont Boiler, In today's session, we will discuss Benson Boiler along with its Definition, Parts, Working, Advantages, Disadvantages & Applications. So let's dive into the article!

Benson Boiler Definition:

Benson Boiler is a high pressure, drumless, supercritical water tube boiler that makes use of forced circulation but has a unique characteristic of the absence of the steam separating drum. Its main principle is that, at the critical pressure, the steam and water coexist at the same density, and heat is zero.

Benson Boiler was invented by Mark Benson in the year 1922.

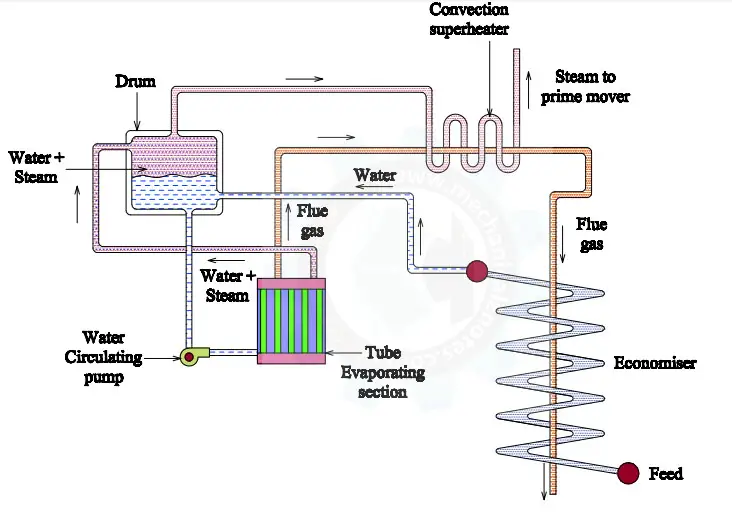

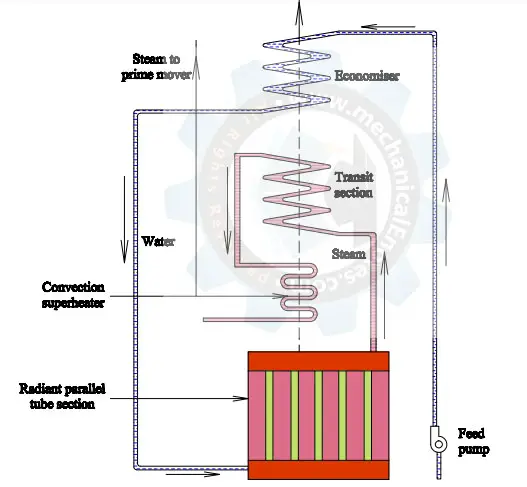

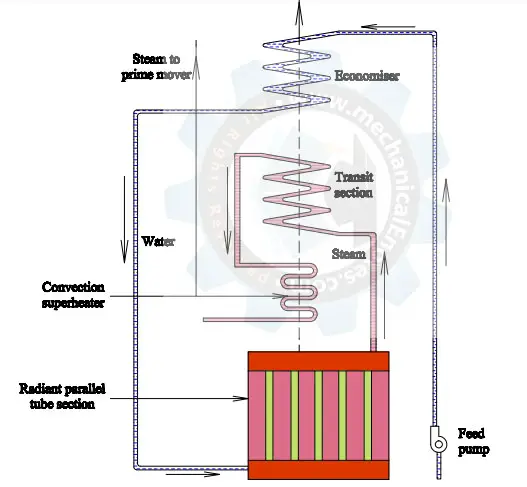

Benson boiler Diagram:

The Benson boiler Diagram is shown below.

Parts or Construction of Benson Boiler:

The parts of the Benson boiler are as follows.

- Feed Pump

- Economizer

- Radiant Parallel tube section

- Transit section

- Convection Superheater

- Steam to the prime mover

The explanation for the Construction or parts of Benson Boiler are as follows:

Feed Pump:

The feed pump supplies the feed water from a hot well into the boiler.

Economizer:

The duty of the Economizer is to preheat the water from the combustion gases by the usage of the remaining heat.

Radiant Parallel tube section:

The collected water is to be sent to the Radiant Parallel tube section such that it evaporates the water-steam mixture with the help of a radiator.

Transit section:

The steam-water mixture produced then moves to the transit section where this mixture is converted into steam.

Convection Superheater:

The steam is passed through the Convection superheater where the steam is heated to high temperatures.

Steam to the Prime mover:

Finally, the steam without water droplets strikes the blades of the turbine to generate electricity.

These are the parts of Benson Boiler. Let's see the working principle of it.

Working Principle of Benson Boiler:

The working of Benson boiler with respect to the above components are as follows:

Firstly, The feedwater passes through the economizer. The function of the Economizer is to increase the temperature of the feedwater (preheating) by absorbing the heat from the flue gases before they are sent to the atmosphere.

The feed water after circulation through the economizer flows through the Radiant parallel tube section to evaporate partly.

The steam-water mixture produced then moves to the transit section where this mixture is converted into steam.

The steam is now passed through the Convection superheater and finally supplied to the prime mover in order to drive the turbine.

As the superheater is an integral part of the process circulation system, no special starting arrangement for superheating is required.

Depending on the size and pressure required, the boiler can be put into service within 10 to 15 minutes.

Benson Boiler Advantages:

The advantages of the Benson boiler are as follows.

- It can be erected in a comparatively small floor area.

- It is light in weight and hence the low cost of the boiler.

- It can be started very quickly due to welded joints

- The transfer of parts is easy as no drums are required.

- The explosion hazards are less as it has only tubes of small diameter and has less storage capacity.

Benson Boiler Disadvantages:

The Disadvantages of the Benson boiler are as follows.

- When water flow is not enough, there are chances that tubes are overheated.

- When impure water is used, the formation of heavy deposits takes place on heated surfaces.

- The control of the boiler for variable loads is difficult.

Benson Boiler Applications:

The applications of the Benson boiler are as follows.

- The Benson boiler has an average operating capacity of 135 Tonne/hour, operating pressure, and temperature of 250 bar and 650°C to generate mechanical power.

- For the production of electrical power, the supercritical boiler is used in various industries to generate steam.

This is a detailed explanation of Benson Boiler. If you have any doubts, you can ask us and we will reply to you in a short period.

More on Boiler:

Babcock and Wilcox Boiler

Cochran Boiler

Lamont Boiler