Lubrication Systems: Splash Lubrication System and Pressure Lubrication System [PDF]

Types of Lubrication Systems: Lubrication is the admittance of oil having relative motion between two surfaces and it also reduces wear and tear between the parts having relative motion.

The purpose of lubrication maybe one or more of the following.

- Cool the surfaces by carrying away heat due to friction.

- Seal a space adjoining the surfaces such as Piston rings and cylinder liner.

- Absorb shock between bearings and other parts and consequently reduce noise.

- Cleaning the surfaces by carrying away the carbon and metal particles caused by wear.

Before discussing on Types of lubrication systems, we need to discuss about Properties of Lubricant.

Properties of Lubricant:

- Fire point:It is the lowest temp at which oil burns continuously.

- Cloud point:When the oil is subjected to low temperature, the change in the state takes places from liquid to plastic or solid-state such that it appears to a cloud called Cloud Point.

- Pour Point:It is the lowest temperature at which the lubricating oil will pour. It is an indication of its ability to move at low temperature.

- Oiliness:Property which enables oil to spread over is called Oiliness.

- Corrosion:Should not corrode the working parts

- Physical and chemical stability:Physically and chemically stable between operating temperatures

- Adhesiveness:Oil particles stick to the metal surface is called Adhesiveness.

- Specific gravity:It is the measure of the density of oil.

Types of Lubrication Systems:

There are two types of Lubrication systems which are presented below:

- Splash Lubrication system

- Pressure Lubrication system

The detailed explanation is as follows...

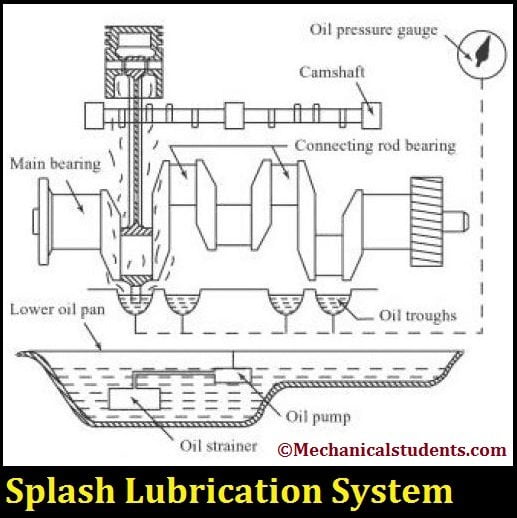

Splash lubrication System:

Splash lubrication is commonly used in early motorcycles engines.

This technique is used in lawn mower and motors or outboard boat engines that should have sufficient amounts of oil in the trough to fully lubricate the machine.

Components of Splash Lubrication System:

The components of Splash Lubrication System are follows:

- Crankcase

- Oil Strainer

- Oil Pump

- Oil Troughs

- Crankshaft

- Scoop

- Piston

- Cam Shaft

- Oil Pressure Gauge

Explanation for the Parts of Splash Lubrication System:

Crankcase:

It is used to store the oil which is passed through the oil galleries for the proper lubrication.

Oil Strainer:

It is used to filter the impurities present in the oil such there should not be any blockage at any part.

Oil Pump:

It is the major part of the lubrication system because it is used to transport the fluid from the crankcase to all the parts of the engine.

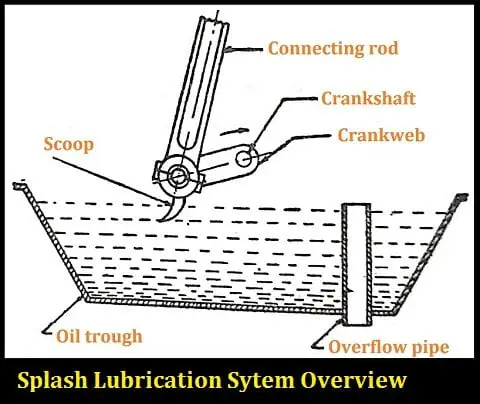

Oil Troughs:

These are provided just below the scoop of piston such that when the piston is in its reciprocating motion, the scoop of piston lifts the oil from the oil troughs such that the oil reach to all the parts of the piston for the lubrication.

Crankshaft:

The reciprocation motion of piston is converted into the rotory motion of crankshaft in the engine cylinder. The power obtained from the crankshat will be transmitted to all the parts of the vehicle.

Scoop:

It is connected at the end of the piston and the scoop of piston lifts the oil from the oil troughs such that the oil reach to all the parts of the piston for proper lubrication.

Piston:

It plays an important role in IC engines. It is present in the engine cylinder and it converts the reciprocation motion into rotory motion of the crankshaft.

Camshaft:

This camshaft consists of cams which are used for operating the valves in the internal combustion engines.

Oil Pressure Gauge:

It is used to measure the pressure of oil in the engine cylinder.

Working of Splash Lubrication System :

Firstly oil is filled in the Crankcase.Oil strainer will remove any impurities present in the oil and the oil pump will supply it to all the parts including oil troughs.

In the splash lubrication system, oil is splashed up from the oil trough or oil trays in the lower part of the crankcase with each revolution of the crankshaft to produce the oil splash.

The oil is thrown upward either as droplets or fine mist and provides adequate lubrication to piston pins,piston rings, valve mechanisms, cylinder walls etc.Oil flows through the holes drilled inside the crankshaft and main bearing to lubricate them.

This system is too uncertain for automotive applications.

Make sure, the crankcase must be filled completely with the oil so that, oil level in the troughs is maintained.

Full of oil in the trough results in oil consumption and excess lubrication whereas slightly low level of oil results in inadequate lubrication and failure of the engine.

Advantages of Splash Lubrication System:

Here are some advantages of Splash Lubrication System:

In some of the automobiles also, the splash lubrication system is used where the machine can do little effort compared to the IC engines.

Disadvantages of Splash Lubrication System:

Also, there are some disadvantages of Splash Lubrication System and those are:

- Due to the presence of scoop at the end of piston, it doesnot serves the proper lubrication throughout the engine cylider. It will just spill the lubricant on to the piston parts.

- Due to this, wear and tear of the components takes place.

- To avoid the incomplete lubrication, Pressure Lubrication System has came into picture.

Note:

Due to the limitation of Splash Lubrication System, Pressure Lubrication system has came into existence.

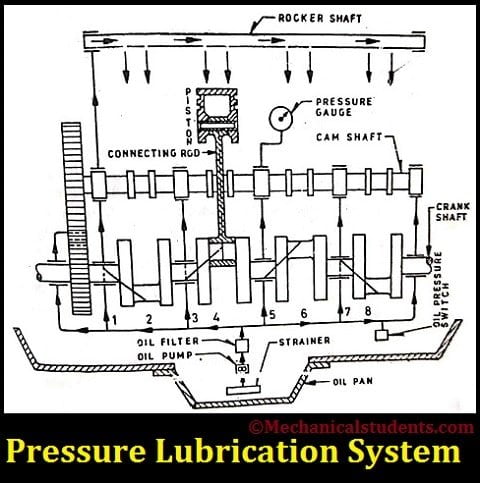

Pressure Lubrication System:

The Pressure Lubrication system is universally used in modern car engines.

The Pressure Lubrication system has come into picture because the Splash Lubrication system is not suitable for automobile engines due to the absence of positive lubrication.

Components of Pressure Lubrication System:

- Crankcase (for oil storage)

- Oil Strainer

- Oil Pump

- Oil Troughs

- Crankshaft

- Oil Galleries

- Piston

- Cam Shaft

- Oil Pressure Gauge

All the components mentioned above are also the components of Splash Lubrication system.Therefore, they are not explained here again.The only compoent which is different from the splash system is Oil Galleries.

Oil Galleries:

These are in the form of pipes which serves the best lubrication compared to splash lubrication system because here there is no case of leakage and the oil will be passed to all the parts of the engine for better lubrication.

Working of Pressure Lubrication System:

In this system, Oil is taken from the wet sump through the strainer by the pump and delivers it at a pressure of 200 to 400 Kpa to the main oil gallery.

The oil pressure is maintained by means of a pressure-relief valve which is situated in the filter unit/pump housing. An oil pressure regulator ensures that the oil pressure level is maintained properly.

For inline engines,one main gallery is used whereas for V-Engines one/two main galleries are used.

The oil filter removes all the dust particles present in the oil and supplies clean oil to all the oil lines. The pressurised oil flows through the oil lines and galleries so as to lubricate the moving engine parts.

Oil from the main gallery flows through the holes drilled inside the crankshaft and main bearing to lubricate them.The oil sprout connected with the gallery, forces the oil upwards to lubricate the piston and all the parts of it from inside.

Oil flows through the oil rings to lubricate and form a thin film around the cylinder walls. After all the parts are lubricated in first gallery, the oil will be pumped to the second gallery which can lubricate all the parts connected with camshaft.

The sprouts connected to the gallery helps in lubricating camshaft,valves and valve springs. After lubricating the engine parts, oil begins to flow downwards through a seperate passage to the sump.A pressure gauge calculates the oil pressure in the system and displays it on the dial.

Advantages of Pressure Lubrication System:

Due to the presence of oil galleries, the oil will be passed through them to reach all the components of engine cylinder and thereby there will be no wear and tear takes place among the mating parts.

Disadvantages of Pressure Lubrication System:

In this system also, if oil was not poured properly into the engine for every servicing then despite of the pressure system also, the parts will wear.

This is the detailed explanation of Types of Lubrication Systems: Splash Lubrication System, Pressure Lubrication System in a detailed way.

If you have any doubts, feel free to ask in the comments section.

Resources:

Classification of IC Engines

Classification of Chasis PDF-FWD, RWD, AWD

References [External Links]:

- Chapter 2 Engine Systems - Navy BMR

- 3 Engine Systems and Fuels | Review of the 21st Century

Media Credits:

- Feature Image: Modified by Author