Vernier Caliper: Parts, Principle, Formula, Least Count, Range, Resolution, Applications, Advantages, and Disadvantages [PDF]

Vernier Caliper is used to measure the dimensions of the given specimen like diameter (Outer Dia and Inner dia), length and depth, etc very accurately that's the reason it is also called as Precision measuring Instrument.

In the last class, we had discussed the concepts on Angular Measurements & Linear Measurements and in today's paper, we will discuss Vernier Caliper in detail.

The Invention of Vernier Caliper:

It was invented by French mathematician Pierre Vernier in 1631.

They usually show either metric or imperial measurements and in some of the cases, it measures both.

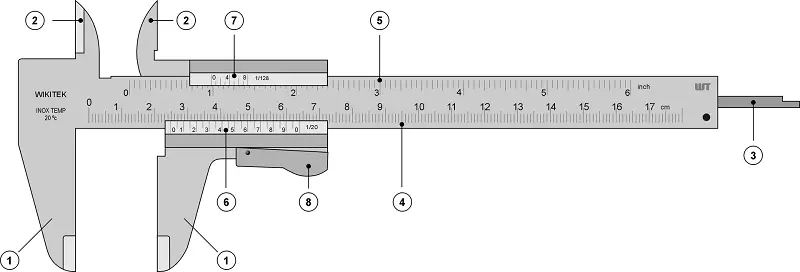

Parts of Vernier Caliper:

A Vernier Caliper has following parts:

- Outside jaws: It used to measure the external dimension of objects.

- Inside jaws: It used to measure the Internal dimension of objects.

- Measuring Depth Probe: It is used to measure the depth of objects.

- Main Scale (cm).

- Main Scale (inch).

- Vernier Scale (cm).

- Vernier Scale (inch).

- Retainer: It used to block the movable part.

Working Principle of Vernier Caliper:

The Vernier Caliper is a Precision Measuring Instrument which is used to measure length, depth, diameter of the given specimen.

The detailed explanation of Vernier Caliper is as follows.

- Calipers are nothing but the Jaws which are used to fix the given component.

- It consists of two jaws and those are Upper Jaw and the Lower Jaw.

- Upper Jaws are used to measure the Inner diameter of the given specimen whereas Lower jaws are used to measure the outer diameter of the given specimen.

- It consists of two scales. One is the Main Scale and the other is the Vernier Scale. Both these scales are measured in Inches as well as in millimeters.

- The locking pin is used to tighten the jaws at the given measurement.

How to Measure the Depth of the given specimen?

The measuring depth probe is used to measure the depth of the given specimen.

How can you check any Measurement?

- In order to calculate the dimensions, the given specimen is to be placed between the two jaws. One is a fixed jaw and the other is a movable jaw.

- The object is to be placed in between the two jaws and is fixed by means of locking pin.

Formula of Vernier Caliper:

The formula of Vernier calipers was shown below.

Measurement= M.S.R + (V.S.R*L.C)

Least Count of Vernier Caliper:

The least count was calculated as follows.

Least Count (L.C)= 1 MSD - 1VSD

How to Read Vernier Caliper in mm?

By knowing the readings of Main Scale Divisons, Vernier Scale Divisons and Least Count, the reading of a specimen can be found and it can be theoretically calculated as follows.

Calculation of Main Scale Division:

If the zeroth division of the vernier scale is coincided with (some number) on the Main scale(consider it as 10) then 10mm is the Main scale Reading(M.S.R).

M.S.R = 10mm.

Calculation of Vernier Scale Division:

After that, you need to check which division on the vernier is exactly coinciding with the main scale as shown in the fig.

- If you see in the figure,10th division in the vernier scale is exactly coinciding with a division on the Main scale. Therefore you need to count the no.of divisions from 0-10.

- The no.of divisions from (0-1) on a vernier scale is 5 divisions.

Therefore,upto (0-10),it is 50 divisons.So,take the Vernier Scale Divison is 50.

V.S.R=50.

Calculation of Least Count:

As we know the formula of Least Count (L.C)= 1 MSD - 1VSD

1 VSD= (49/50) MSD= 0.98 MSD

Substitute the above value in the formula of Least Count (L.C)= 1 MSD - 1VSD

Therefore,

Least Count (L.C) =1 MSD - 0.98 MSD= 0.02 mm

Therefore, the Least Count of Vernier Caliper is 0.02 mm.

Measurement= M.S.R + (V.S.R*L.C) = 10+ (50*0.02) = 10+1 = 11mm

Therefore, the reading on Vernier Caliper is 11 mm.

Here is a Video on How You Can Measure on Vernier Caliper:

Range of Vernier Caliper:

The range of a vernier caliper is the difference between the largest value and the smallest value that a caliper can measure and It is equivalent to the length of the main scale.

Mostly, vernier calipers have a range of 6 inches i.e. 300mm.

Resolution of Vernier Caliper:

A Caliper's resolution is indicated at the end of the vernier scale and it is the smallest distance that the caliper can measure.

The resolution of Vernier Caliper are:

- Imperial vernier calipers is usually 0.001 in, whereas for

- Metric calipers is either 0.05mm or 0.02mm.

What is the difference between a dial caliper and a Vernier caliper?

In almost all industries people were using the vernier caliper, not of dial mode and thereby there is a little chance(in terms of microns) that they will get an error.

The basic difference between the standard vernier and the Dial Vernier is as follows.

Dial Caliper or Digital Vernier: Direct Reading (Perfect Reading) will be displayed.

Standard Vernier: Manual Reading (You need to check manually).

Instrument error or Tolerance:

An Instrument error refers to how accurate a vernier caliper is.

Low tolerance measuring tools provide very accurate results with a small margin for error and Vernier calipers is one of them.

Applications of Vernier Caliper:

Some of the applications of vernier calipers are listed below:

- Educational Sector

- Steel Industries

- Science Labs

- Aerospace Industries

- Medical Purposes

Advantages of Vernier Caliper:

Accuracy and Precision:

They provide precise and accurate measurements over a large range.

Versatility:

It can have the ability to measure any type of dimensions of a component, for example:

- It can measure the outer diameter of the given component.

- It can measure the Inner diameter of the given component.

- It can measure the depth of the given component.

- It can measure the length of the given component.

Durability:

As the Vernier is made up of Stainless steel(Anti-Corrosive material), it can sustain for a long period of time and thereby its durability will be high.

Cost:

It is relatively less expensive compared to other calipers.

Ruler or Measuring Tapes:

If you want the accuracy, you should have to leave the rulers or measuring tapes for the measurement of any component.

Disadvantages of Vernier Caliper:

Possibility of Errors:

It needs much concentration to read a dimension of the component else there is a possibility of error.

Accurate Tools:

If you are unable to use vernier calipers, then you can go for the other accurate tools present in the industry like Dial Caliper.

Magnifying Glass or Eyesight:

Good Magnifying glass is required during taking the measurement of any component if your eyesight is not proper else it results in taking the errors as the original measurement.

This is the detailed explanation of Vernier Caliper along with its Formula, Construction, Experiment. If you like this article, Then share it with all your friends.

READ MORE FROM US

Sine bar – Principle, Formula, Construction, Limitations&Factors

3 Types of Marking Out Tools used in Fitting – Engineering Workshop

References [External Links]:

- Caliper - an overview | ScienceDirect Topics

- Experiments 1-5.pmd - ncert

- Vernier Calipers Made Easy - Physics

Media Credits:

- Image 1: CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=314653

- Digital Vernier: Indiamart

- Vernier GIF: By Lookang many thanks to Fu-Kwun Hwang and author of Easy Java Simulation = Francisco Esquembre - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=15912813

- Video by: SMUPhysics