Types of Measuring Instruments and their Uses in Engineering Workshop [PDF]

Measuring Instruments plays a vital role in the Engineering Workshop. The Instruments duty is to measure the given specimen according to the given dimensions. So in today's class, we will be discussing on Types of Measuring Instruments and their Uses in Engineering Workshop.

In the last class, we had discussed Angular Measurements and Linear Instruments in a detailed way.

Before knowing the instruments, you need to know the units of measurement in both C.G.S and M.K.S System and are as follows.

1. Metric system(C.G.S)

- Length is measured in centimeter (cm)

- Mass is measured in grams (gm)

- Time is measured in second (s)

2. S.I system(M.K.S)

- Length is measured in meter (m)

- Mass is measured in Kilograms (kg)

- Time is measured in second (s)

Measuring Instruments and their Uses in Engineering Workshop:

The 10 types of Measuring Instruments and their uses are presented below.

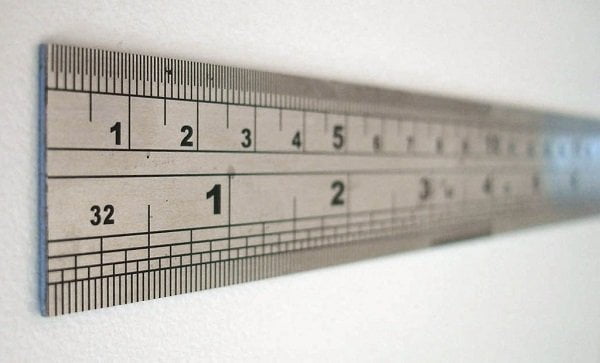

1. Steel rule & Measuring Tape

Steel Rule:

- It is an instrument in geometry which is used to measure the length, breadth, and height of the given specimen

Measuring Tape:

- It is a flexible form of a ruler.

- It is calibrated in terms of mm, cm and inches.

2. Surface Plate

The Surface plate is used for testing the flatness of a w/p.It is also used for Precision inspection, marking out layout and tooling setup.

The surface plate is a common tool used in industry and is often permanently attached to robotic-type inspection devices such as a coordinate measuring machine.

Accessories used along with Surface Plate:

The surface plate is used in conjunction with accessories such as a

- Dial indicator

- Sine bar

- angle plate

- straight edge

- gauge blocks

- height gauge etc.

Precision:

- It is more precise than the marking table.

Material:

- The surface plate is made up of Cast Iron(C.I.) or hardened steel or Granite stone

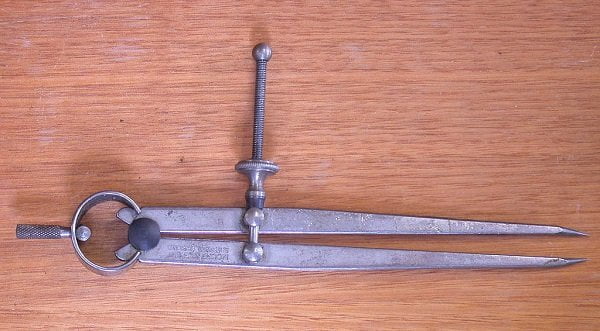

3. Divider:

Divider is used for marking circles, arcs, laying out perpendicular lines, bisecting lines, etc. Divider Calipers are used in the process of marking out suitable workpieces.

Explanation of Divider:

- The Points are sharpened so that they act as a scribe.

- One leg can then be placed in the dimple or hole created by a center punch and the other leg is pivoted so that it scribes a line on the workpiece surface, thus forming an arc or circle.

4. Trysquare:

- It is used for marking and checking the right angles (Flatness & Squareness) of the given workpiece.

- These Try squares come in various sizes from 75mm-300mm.

5. Inside caliper:

The inside caliper is used to measure the internal size of an object. It consists of two legs which are not inverted to each other and are connected by means of a screw and nut mechanism.

Apart from that, the usage of Inside Caliper was also placed in this article.

Uses of Inside Caliper:

- The two legs of the Inside Caliper are adjusted on to the workpiece in such a way that the legs can touch the surface until they will almost pass over the object.

- The Inside Caliper has an adjusting screw that permits it to be carefully adjusted without removal of the tool from the workpiece.

6. Outside Caliper:

The Outside caliper is used to measure the external size or Outer size of an object. It consists of two legs which are inverted to each other and are connected by means of a screw and nut mechanism.

Apart from that, the usage of outside Caliper was also placed in this article.

Uses of Outside Caliper:

- The same observations and techniques are applied to the outside caliper compared with inside caliper.

- With some understanding of their limitations and usage, these instruments can provide a high degree of accuracy and repeatability.

- They are especially useful when measuring over very large distances i.e.for example to measure a large diameter pipe.

- A vernier caliper does not have the depth capacity to straddle this large diameter while at the same time reach the outermost points of the pipe's diameter.

- They are made from high carbon steel.

7. Odd-Leg Caliper:

- This is also called “Jenny Caliper”.

- This is used for marking parallel lines from a finished edge and also for locating the center.

8. Vernier Calipers:

- Vernier Callipers is used to measure the dimensions of the given specimen like diameter(Outer Dia and Inner dia), length and depth etc. For detailed information, click on the below link.

- L.C. of Vernier Callipers is 0.02 mm.

9. Micrometer

A micrometerr is used to measure the diameter of the given specimen only. It is not used to measure the depth of an object which can be done by measuring the depth probe of Vernier calipers.

- L.C. of Micrometer is 0.01 mm.

10. Vernier Height Guage

- A height gauge is a measuring device used either for determining the vertical distances or for the repetitious marking of items to be worked on.

- The capacity of the height gauge is specified by the maximum height it can measure.

- It varies from 150 mm to 1000 mm.

This is the complete explanation of types of Measuring Instruments and their Uses in a detailed way.

Reference:

- What are the different types of caliper? - Wonkee Donkee Tools

- Engineering Metrology - IIT Kanpur

Media Credits:

- Image 1: By Ejay - Own work, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=3580052

- Image 2:By Rrudzik - Own work, CC0, https://commons.wikimedia.org/w/index.php?curid=15301586

- Image 3:By Glenn McKechnie - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=916081

- Image 4:By Luigi Zanasi - Own work, CC BY-SA 2.0 ca, https://commons.wikimedia.org/w/index.php?curid=331123

- Image 5:By Glenn McKechnie - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=916089

- Image 6:By Glenn McKechnie - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=916098

- Image 7:By Glenn McKechnie - Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=916069

- Image 8:CC BY-SA 2.5, https://commons.wikimedia.org/w/index.php?curid=314653