Types of Angular Measuring Instruments [PDF]

Angular Measuring Instruments are the devices that are used to measure the angle of the given specimens.

Types of Angular Measuring Instruments:

There are various types of Angular Measurements which are based on various standards, and those are the following:

- Line Standard Angular Measuring Devices

- Protractor

- Universal Bevel Protractors

- Face Standard Angular Measuring Devices

- Sine bar

- Angle Gauges

- Measurement of Inclines

- Spirit Level

- Clinometer

- Angle Comparators

- Angle Dekker

The explanation of the above Angular Measurements is as follows.

Line Standard Angular Measuring Devices

The explanation of Protractor and Bevel Protractor is as follows. The basic difference between them is, the protractor is used to measure the angle of the flat surfaces whereas the bevel protractor is used to measure the angles of inclined surfaces.

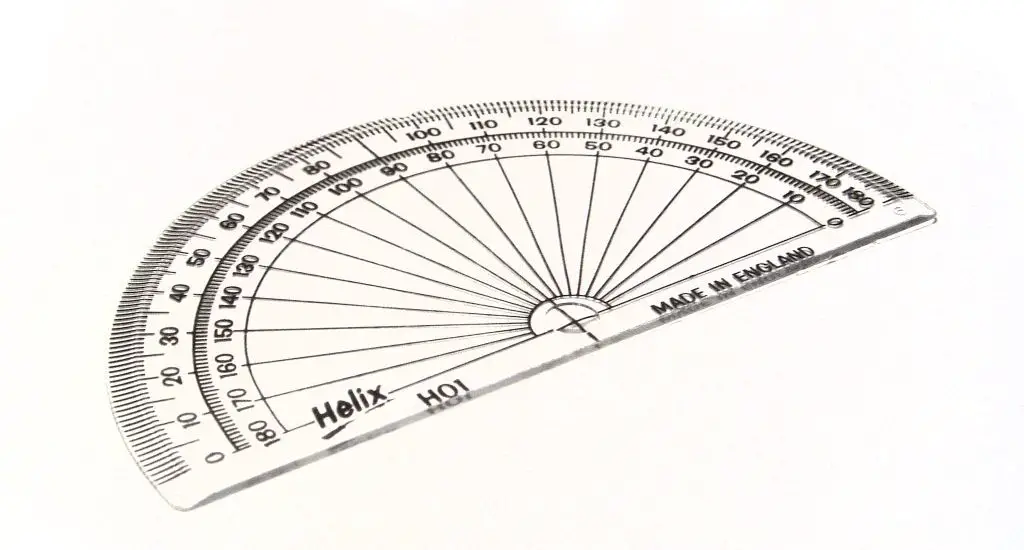

Protractor:

It is a piece of simple angular measuring equipment used for measurement of angles from zero degrees to 180 degrees with an accuracy of + or -0.5 degree.

This is generally used for measurement and setting of angles in drawings only.

Bevel Protractor:

It is used to measure the angle of the given specimen by placing the component in between the two blades of the bevel protractor.

It is calibrated in Main Scale Divisions and Vernier Scale Divisions. Main scale on the protractor is divided into degrees from 0-90 each way such that it can complete 180 degrees.

The Vernier scale has 12 Divisions and they are divided into (0-60)minutes such that each division is equal to 1/12th of 60. i.e. 5 mins.

Therefore, the least Count of Bevel Protractor is 5 minutes.

Face Standard Angular Measuring Devices

Sine bar:

It is used to measure the angle of the given specimen by the usage of Slip gauges. The sine bar is made up of high carbon steel.

For more info Principle, Formula, Construction, Limitations & Factors of Sine bar, Click here.

Angle Gauges:

There are 13 Angle Gauges from 0 degree to 81 degrees.

During the building of a given angle by using an angle gauge set, the following points must be ensured.

- Every single gauge used must be available in the standard set.

- Do not repeat the same Angle gauge in one setting.

Note:

When 2 slip gauges are given, it is possible to build only 1 dimension whereas when 2 angle gauges are given, it is possible to build 2 different angles.

Angle gauges are used as a reference gauge or masterpieces for calibrating the angular measuring equipment.

Measurement of Inclines

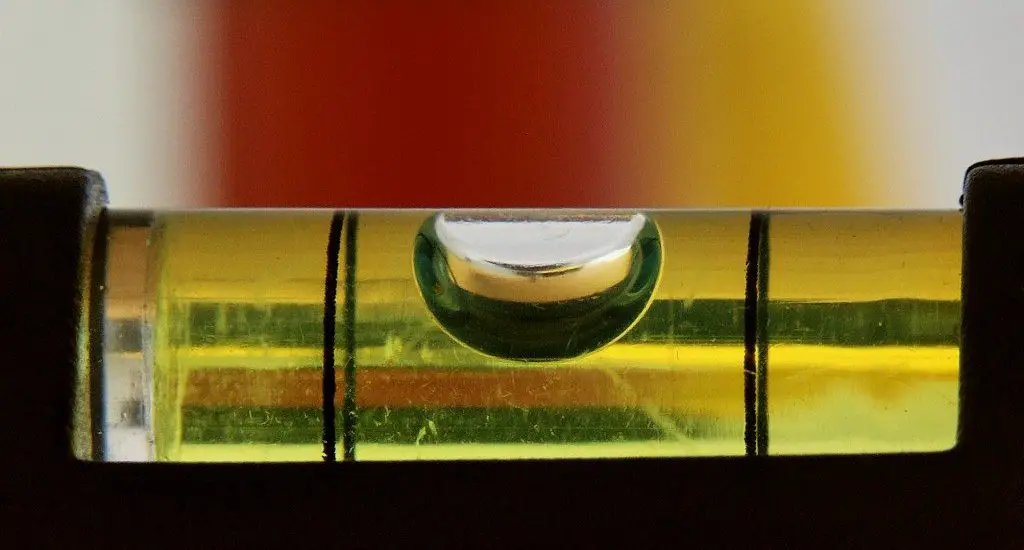

Spirit level:

In general, the spirit level will not be used for measurement of the angles, but it will be used for the measurement of angular deviations or angular errors only.

The body of the spirit level is made by using very low-density material because the weight of the spirit level must be as minimum as possible to avoid the disturbance taking place on the angular deviations.

Spirit is used as a liquid because it has low density or viscosity and the wettability of spirit with a glass surface is zero.

Note:

- The length of one scale division must be greater than the diameter of the air bubble. To ensure that only one division must be present within the air bubble.

- The air bubble is always set at the topmost point of the curvature so that when the spirit level is placed on the perfectly flat surface, the air bubble is setting at the Zero location.

Sensitivity of Spirit Level:

The sensitivity of the spirit level can be increased by increasing the radius of the glass vial.

Theta (θ) = mm/m

If the sensitivity of the spirit level is indicated in terms of mm/m, it is called a gradient of a spirit level.

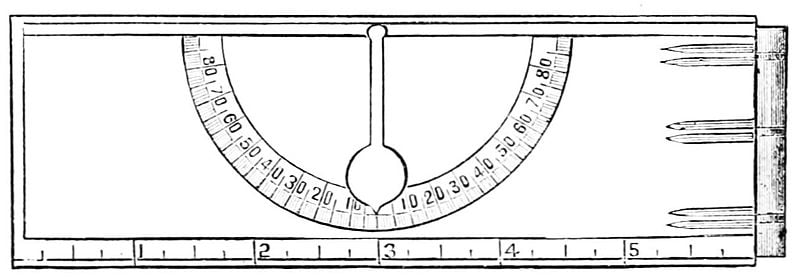

Clinometer:

Individually, Protractor and Spirit Level cannot be used for the measurement of angles of a component.

Therefore by combining protractor and spirit levels, it is possible to measure the angle of the component which is called a Clinometer.

It is a piece of simple angular measuring equipment used for measuring an approximate angle of the component.

This can measure the accuracy of the angles up to 0.5 degrees and any unknown projections present in the component will also create errors in the angle measured.

Angle Comparators

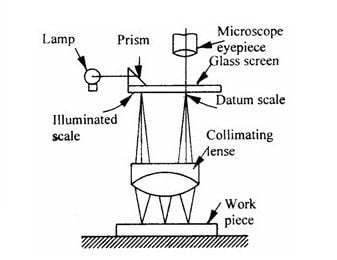

Angle Dekker:

It is not the direct angle measuring equipment but it is an angle comparator that compares the angle of the given component with a standard set of masterpieces which can also be taken as Angle gauges.

By using any linear measuring equipment, measure the linear dimension of a component like h1, h2, L...etc. and calculate approximately the angle of the given component.

Let Theta (θ) Approx. = 29°40'

Where ° indicates degrees and ' indicates minutes

Corresponding to Theta (θ)Approx., built the angle gauges and keep it below the optical head and switch on the optical head because of an incident ray of light and reflected ray of light, the scales are observed to be distributed completely which is shown in the figure.

By using the knobs, adjust the scales in such a way that both the scales will be coming to the center of each other.

Now fix the knobs by removing the angle gauges from the optical head and keep the actual component whose angle is to be measured below the optical head because of the presence of difference of the actual angle of the component and approximate angle, the reflected ray is in the different direction.

Therefore the skills are observed to be distributed completely.

By rotating the job slowly, scales are adjusted such that the horizontal scale will come to the center of vertical scale from where we can get a value (n=23)

Theta (θ) Actual = Theta Approx. (+/-)0.2' *n = 29°40' (+/-)0.2'*23= 29°40' (+/-)4.6'

Where ° indicates degrees and ' indicates minutes

Note:

- If the vertical scale is traveling towards the right, a positive sign is to be taken.

- If the vertical scale is traveling towards the left, a negative sign is to be taken.

Therefore,

Theta (θ) Actual = Theta (θ) Approx.+(0.2' *n)= 29°40' +(0.2'*23)= 29°40' + 4.6'= 29°44.6'= 29° 44' 36"

Where ° indicates degrees and ' indicates minutes

This is the explanation of Angular Measurements or Angular Measuring Devices in a detailed way. If you have any doubts, feel free to ask in the comments section.

References [External Links]:

- unit 6 angular measuring devices - IGNOU

- Unit 3: Sine Bar – Manufacturing Processes 4-5 - Pressbooks

- What is a bevel protractor? - Wonkee Donkee Tools

Media Credits:

- Protector Image: By Zephyris at the English language Wikipedia, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=5024047

- Sine Bar Image: By Hans-Günter König, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=751250

- Spirit Level Image: By aTarom - Own workCámara: DiMAGE 7HiISO: 100Tv: 1/2Av: 9.5, Public Domain, https://commons.wikimedia.org/w/index.php?curid=963213

- Clinometer Image: Public Domain

- Feature Image: Modified by author