Draft tube: Definition, Function, Types, Applications, Advantages, Disadvantages, and Efficiency [Notes with PDF]

If you had observed our previous articles, you can notice that there is a component called Draft Tube which is attached to the end of the Kaplan Turbine and Francis Turbine. In this article, we elaborate on the Draft Tube along with its Definition, Function, Types, Applications, Advantages, Disadvantages, Efficiency, and Design calculation.

Now, Let's discuss the Definition of the Draft Tube.

Draft Tube Definition:

A Draft tube is a kind of tube that acts as an important part of the reaction turbine and also acts as an intermediate between the exit of the turbine and the entry of the tailrace. The water is discharged to the tailrace through a gradually expanding tube called the Draft tube.

The water channel that carries away from the turbine is called the Tailrace.

Draft Tube Function:

The function of the Draft tube is to reduce the velocity of the fluid coming out from the exit of the turbine and increases the pressure of the fluid up to the atmospheric level at the tailrace.

Types of Draft Tube:

There are three types of Draft tubes and are as follows.

- Simple Elbow type draft Tube

- Elbow type with varying cross-section

- Straight divergent tube or Conical diffuser

Simple Elbow type draft Tube:

This type of daft tube can be generally used when the turbine has to be placed close to the tail race. As the name indicates it consists of an extended elbow type tube as shown below.

The efficiency of the Simple Elbow type draft tube is 60%. In order to recover the kinetic energy at the outlet of the runner, the exit diameter should be large.

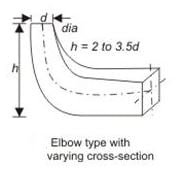

Elbow type with varying cross-section:

The bent part of the draft tube is of the varying cross-section with a rectangular outlet which is similar to that of the bent draft tube.

The height of the draft tube is represented by 'h' and is equal to 2d to 3.5d where 'd' represents the diameter of the draft tube at its entry as shown in the figure.

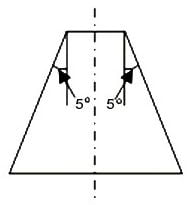

Straight divergent tube or Conical diffuser:

The straight divergent tube is generally employed for a low specific speed and its efficiency is 90%.

To prevent flow separation, this draft tube consists of a conical diffuser with a half-angle less than equal to 10° as shown in the below figure.

Applications of Draft Tube:

The applications of Draft Tube are as follows.

- This draft tube is mostly used in Hydroelectric power plants.

- .You can see the usage of the draft tube in the Kaplan turbine and Francis turbine as a common part.

Advantages of Draft Tube:

The advantages of Draft Tube are as follows.

- At tailrace, the amount of kinetic energy decreases due to the usage of the draft tube.

- The splashing water coming out from the runner was prevented by the usage of the draft tube which guides the water to the tailrace.

Disadvantages of Draft Tube:

The disadvantages of Draft Tube are as follows.

- Without the usage of a draft tube, there is a pressure drop developed due to the lack of water and thereby the entire turbine can fail because the turbines need a minimum amount of water to propel and to produce energy.

- To inspect the turbine properly, the draft tube must be placed above the tailrace without any loss of net head.

The efficiency of Draft tube:

The efficiency is calculated as follows.

The efficiency of a draft tube (Ƞd) = Actual conversion of the kinetic head into the pressure head to the kinetic head at the inlet of the draft tube.

Ƞd = (Actual conversion of kinetic head into pressure head) / (kinetic head at the inlet of the draft tube)

Ƞd = [ ( V12 / 2g ) – ( V22 / 2g ) – hf ] / ( V12 / 2g )

Actual conversion of kinetic head into pressure head = [ ( V12 / 2g ) – ( V22 / 2g ) – hf ]

Theoretical conversion of kinetic head into pressure head = [ ( V12 / 2g ) – ( V22 / 2g ) ]

This is the detailed explanation of the Draft tube. If you have any doubts, you can ask us and we reply to you within 24hrs.

More Resources:

Kaplan Turbine

Pelton Wheel Turbine

Hydroelectric Power plant

Francis Turbine