Difference Between Nano, Macro, Micro and Smart Material [PDF]

Every component or material has its own features and depending upon the application or usage those materials are taken into consideration for Industrial applications. Nano Material has its demand in the field of communications in the form of fibres.

Similarly, smart materials are highly in demand because they can react according to the environment. Therefore, in this article, I will be explaining about the Difference between Nano Material Macro Material, Micro Material and Smart Material along with their applications.

Difference between Nano Material, Macro Material, Micro Material, and Smart Material:

1. Nano Material:

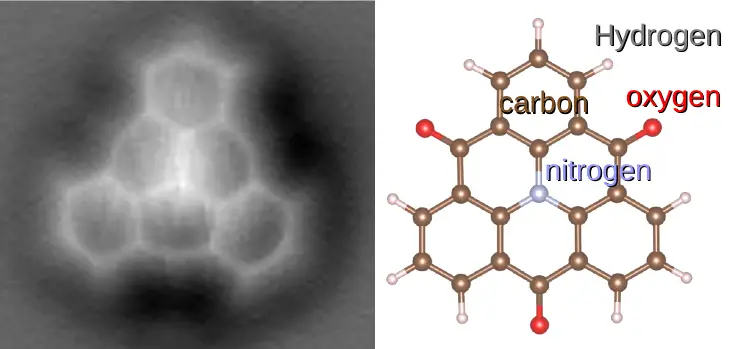

In a component, if anyone of the dimensions i.e.(length, Dia, thickness etc.) is of the order of less than 100 NM (or) if a grain size in a material is of the order of less than 100 NM is known as Nano Material.

Applications of Nano Material:

- Nanomedicine

- Energy applications of nanotechnology

- Potential applications of carbon nanotubes

- Industrial applications of nanotechnology

- Nanoart

- Nanobiotechnology

- Green nanotechnology

2. Macro Material:

In a component, if any one of the dimensions i.e.(length, Dia, thickness etc.) is of the order equal to 5 mm (or) If a grain size in a material is of the order of equal to 5 mm is known as macro material.

3. Micro Material:

In a component, if any one of the dimensions i.e.(length, Dia, thickness etc.) is of the order equal to 5 Micrometer (or) If a grain size in a material is of the order of equal to 5 Micrometer is known as micro material.

Note: As size decreases, defect size decreases and that results to the increment of strength. It means Strength is inversely proportional to Defect size.

4. Smart Material:

If you material functions based on its surrounding environment is called as Smart Material.

For example: Quartz, Silicon dioxide.

The voltage generated across the Quartz sensor is the function of the surrounding pressure of the sensor.

Examples:

- Considered a container which is filled with a pressure of 5 bar and it is running by means of electric current.

- Consider that the set voltage of that particular electric circuit is equal to 5 Millivolts.

- If the electric circuit voltage is greater than 5 Millivolts, then it should have to close the valve and if it is less than 5 Millivolts, then it should have to open the Valve.

- If this process is doing by means of pressure sensors then it is considered to be a smart material or else if the same is done by means of a manual operator then it is called as manual functioning but here, in this case, the pressure sensor itself is regulating the voltages and is taking the decisions so by this,we can conclude that it is a Smart Material.

- According to the definition, If a material functions based on its surrounding environment that it is known as smart material that and this example is a case of smart material.

Applications of Smart Materials:

The applications of smart materials include artificial muscles, actuators, sensors, electroactive polymers etc.

This is the complete explanation of the article Difference between Nano Material, Macro Material, Micro Material, and Smart Material and from this article, you come to know about the differences of all the four materials and this will be most useful in your interviews.