Winter & Summer Air Conditioning System [PDF]

Before knowing about Air conditioning, you should have to know about the concept of Psychometry.

In the last article, we discussed Refrigeration-Introduction, Vapor Compression Refrigeration Cycle & Vapor Absorption Refrigeration Cycle.

Psychometric Properties: Properties of a mixture of air and water are called psychometric properties.

Dry air: Pure dry air is a mixture of no. of gases such as nitrogen, oxygen, CO2, H2, Argon, Neon, Helium, etc.

Atmospheric air which is having 79% nitrogen and 21% oxygen by volume is considered dry air.

Moist air: Moist air is the mixture of dry air and water vapor.

Saturated Air: It is a mixture of dry air and water vapor when the air has diffused the max amount of water Vapor into it.

Degree of saturation: It is the ratio of the actual mass of water vapor in a unit mass of dry air to the mass of water vapor in the same mass of dry air when it is saturated at the same temperature.

Dry bulb temperature (DBT): Dry bulb temperature refers to the temperature of air measured with an ordinary thermometer when it is not affected by the moisture present in the air.

Wet-bulb temperature (WBT): Wet-bulb temperature refers to the temperature of air measured with an ordinary thermometer when its bulb is surrounded by a wet cloth exposed to the air.

Humidity ratio or Specific Humidity: This is given by the ratio of the mass of water vapor to the mass of dry air.

Relative Humidity: It is the ratio of the partial pressure of the Water Vapor in the mixture to the saturated partial pressure at the dry bulb temperature.

Air Conditioning:

Air Conditioning deals with the study of Conditioning of air i.e. maintaining and supplying desirable internal atmospheric conditions for human comfort, irrespective of external conditions.

Factors affecting the Comfort Air Conditioning or Comfort Parameters:

The comfort parameters are as follows.

- Temperature of Air

- Humidity of Air

- Purity of Air

- Motion of Air

The explanation of the above comfort parameters is as follows.

1. The temperature of Air:

The control of temperature means maintaining the desired temperature within the enclosed space even though the outside air temperature is above or below the desired room temperature.

2. The humidity of Air:

The control of humidity of air is maintained either by increasing or decreasing the moisture content of air during summer or winter respectively.

- The relative humidity should not be less than 60% for Summer Air Conditioning,

- For Winter Air Conditioning, the relative humidity should not be more than 40%.

Classification of Air Conditioning Systems:

The air conditioning system may be broadly classified as follows:

- Summer air conditioning system.

- Winter air conditioning system.

- Year-round air conditioning system.

- According to the purpose of the Comfort air conditioning system.

- Industrial air conditioning system.

- According to the arrangement of equipment central air conditioning system.

Summer Air Conditioning System:

Initially, during summer, the dry bulb temperature is high and the relative humidity of the air is low.

Relative humidity should not be less than 60% according to the comfort conditions for summer air conditioning.

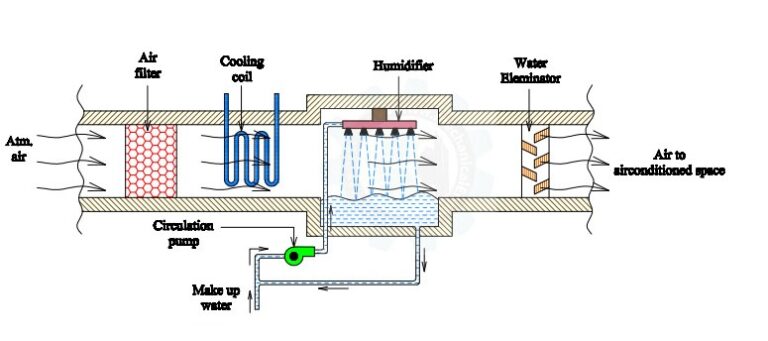

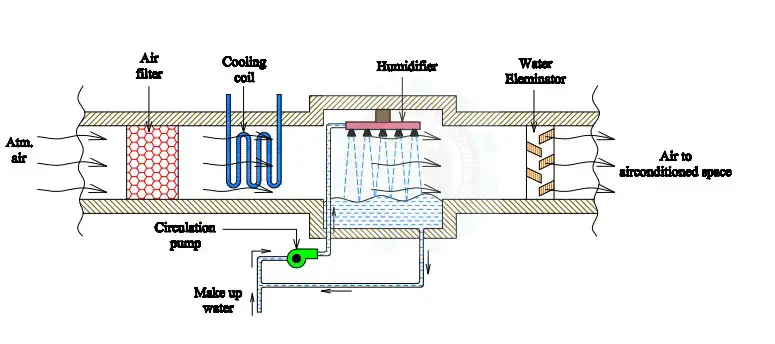

Summer Air Conditioning System Diagram:

The diagram of the summer air conditioning system is shown below.

Working on Summer air conditioning system:

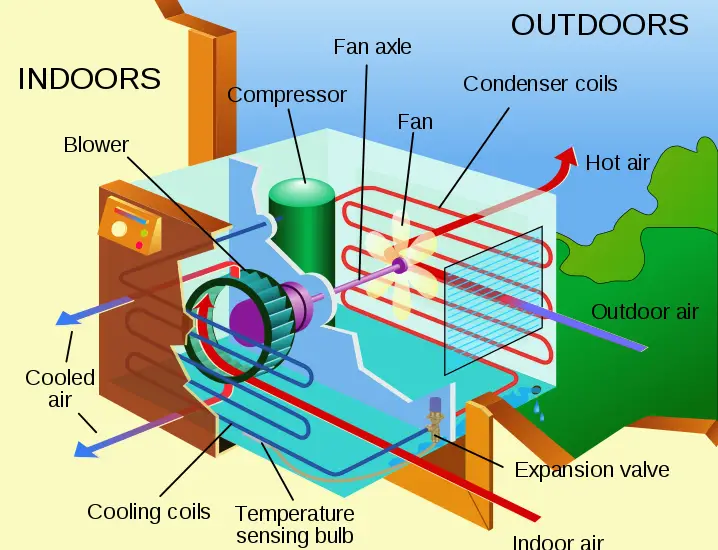

The outside air(atmospheric air) flows through the air filter to remove impurities or dust particles present in the air. The air now passes through a cooling coil.

The coil has a temperature much below the required dry bulb temperature of the air and very high relative humidity in the conditioned space.

So the cooled air is pumped into a dehumidifier, where it loses its moisture in the conditioned space.

After that, the air is made to pass through a heating coil which heats the air slightly.

This is done to bring the air to the designed DBT and relative humidity(RH).

Now the conditioned air is supplied to the conditioned space by a fan.

From the conditioned space, a part of the used air is exhausted to the atmosphere by the exhaust fans or ventilators.

The remaining part of the used air is again conditioned.

The outside air is sucked and it is made to mix with the recirculated air to make up for the loss of conditioned air through exhaust fans or ventilation from the conditioned space.

Winter Air Conditioning System:

In the winter AC System, the inlet is heated by the heater, and in the winter season due to less presence in the air, we also need to add the moisture particle to the air, generally, a humidification system is added to maintain the moisture quantity.

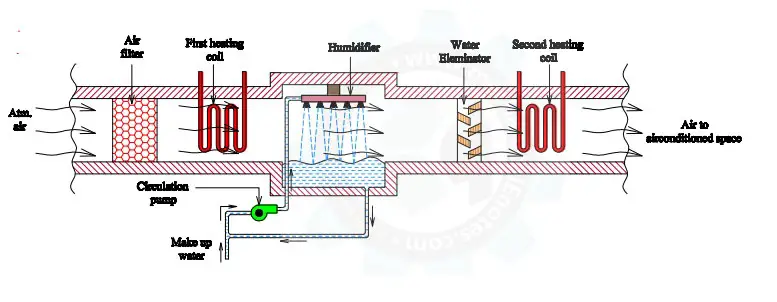

Winter Air Conditioning Diagram:

The Winter Air Conditioning Diagram is shown below.

Working of Winter Air Conditioning System:

In winter air conditioning, the air is heated and is accompanied by humidification.

The outside air flows through a damper and mixes up with the recirculated air which is obtained from the conditioned space.

The mixture here passes through a filter to remove dirt, dust, and other impurities.

The air now passes through a preheat coil to prevent possible freezing of water due to which dry bulb temperature increases to a very high value and the relative humidity drops to a low value.

This air is being pumped into the humidifier.

So, humidification of air (addition of moisture) is done and then the air is made to pass through a reheat coil to bring the air to the designed dry bulb temperature.

Now the conditioned air is supplied to the conditioned space by means of a fan. From the conditioned space, a part of the used air is exhausted into the atmosphere by the exhaust fans or ventilators.

The remaining part of the air known as recirculated air is again conditioned as shown in the figure.

Initially, the relative humidity is 60% in the winter season, so to reduce it, a process of reheating is done where it is reduced to 20%.

So it is again humidified due to which it reaches a point of 80% or 100% RH where the DBT is very low.

So in order to get the desired dry bulb temperature, again the process of reheating is done where the desired percentage of 40% RH is also obtained.

A damper is used in order to control the area and have an intake of the required amount of air.

READ MORE FROM US:

Refrigeration

Reference [External Links]:

Media Credits:

Feature Image: Modified By Author

Window AC 3D diagram: By Pbroks13 - Own work by uploader; The New Book of Knowledge 1997. p. 102., CC BY 3.0, https://commons.wikimedia.org/w/index.php?curid=5986482