Vapour Compression Refrigeration Cycle: Components, Working Principle, Process, Advantages, Disadvantages & Applications [PDF]

Vapour Compression Refrigeration Cycle is the most widely used refrigeration system. In this system, the working fluid is a vapor. It readily evaporates and condenses or changes alternatively between the vapor and liquid phase without leaving the refrigerating plant.

During evaporation, it absorbs heat from the cold body and this heat is used as its latent heat for converting it from liquid to vapour whereas in Condensing or cooling, it rejects heat to external bodies, thus creating a cooling effect in the working fluid.

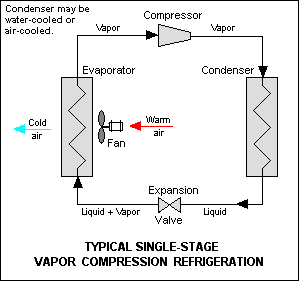

Components of Vapour Compression Refrigeration System:

The figure above consists of the following five essential parts, those are:

- Compressor

- Condenser

- Receiver

- Expansion Valve

- Evaporator

The detailed explanation of the above parts is as follows.

1. Compressor:

The vapour at low pressure and low temperature enters the compressor from the evaporator where it is compressed to high pressure and high temperature.

This high pressure and temperature vapour refrigerant are discharged into the condenser through the discharge valve.

2. Condenser:

The condenser or cooler consists of coils of pipe in which the high pressure and temperature vapour refrigerant are cooled and condensed.

The refrigerant while passing through the condenser gives up its latent heat to the surroundings condensing medium which is normally air or water.

3. Receiver:

The condensed liquid refrigerant from the condenser is stored in a vessel known as a receiver from where it is supplied to the evaporator through the expansion valve.

4. Expansion Valve:

It is also called a throttle valve. Its function is to allow the liquid refrigerant under high pressure and temperature to pass through it where it reduces its temperature and pressure.

5. Evaporator:

It also consists of coils of pipe in which liquid-vapour refrigerant at low pressure and temperature is evaporated and converted into vapour refrigerant at low pressure and temperature.

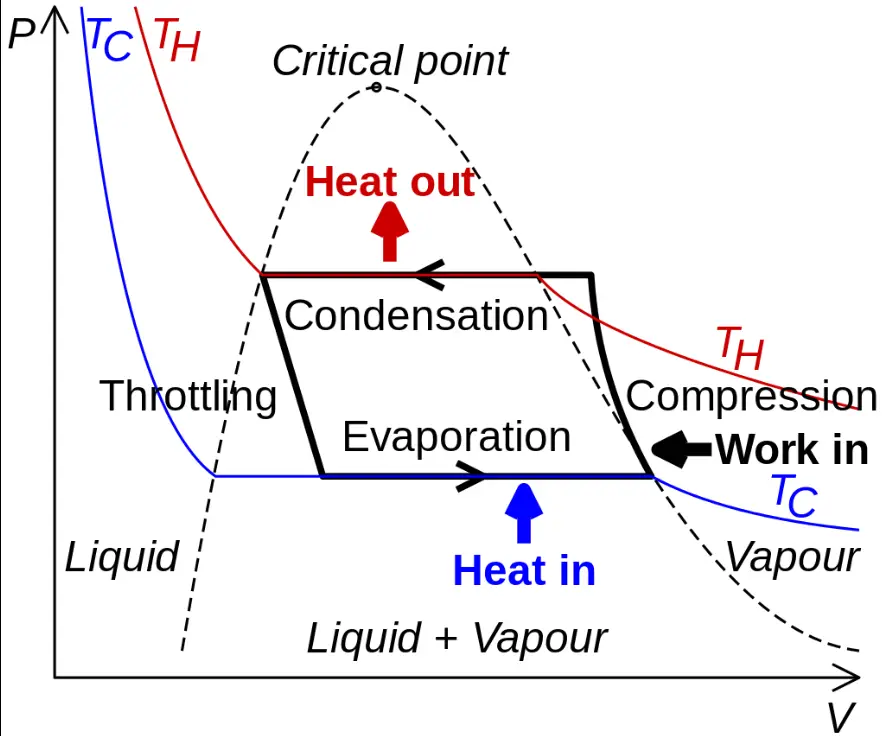

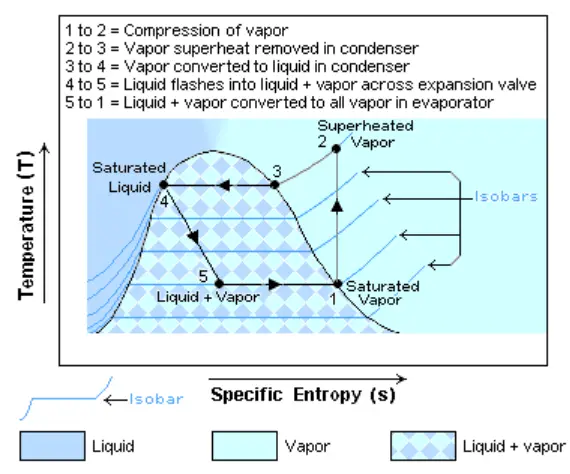

P-V and T-S Diagram of Vapor Compression Refrigeration System:

Working of Vapor Compression Refrigeration System:

The working of Vapor Compression Refrigeration System can be completed under 4 processes and are as follows.

Compression Process:

The vapour at low temperature and low pressure enter the compressor where it is compressed isentropically and subsequently, its temperature and pressure considerably increase.

Condensation Process:

This vapour after leaving the compressor enters into the condenser, where it is condensed into high-pressure liquid and is collected in a receiver tank.

Expansion Process:

From the receiver tank, it passes through the expansion valve, where it is throttled down to low pressure and temperature.

Vaporization Process:

After finding its way through an expansion valve, it finally passes onto the evaporator, where it extracts heat from the surroundings or circulating fluid and vaporizes to lower pressure vapour.

If expansion takes place without throttling, temperature level drops to a very low level due to which it should undergo sensible heat and latent heat in order to reach the evaporation stage.

Note:

- Work is done by the compressor.

- The heat extracted from the evaporator is the difference of heat entering the evaporator and heat leaving the evaporator.

C.O.P. of Vapor Compression Refrigeration System:

The Coefficient of Performance(C.O.P) of a Simple Vapor Refrigeration Cycle is as follows.

C.O.P. = (heat extracted or refrigerating effect)/Work done.

C.O.P. = (h2-h1)/(h3-h2)

or

C.O.P. = (h2-h4)/(h3-h2).

[h1=h4, since during throttling expansion 4-1, the total heat content remains unchanged.]

Types of Vapor Compression Cycles:

The types of Vapor Compression Cycles which are important from the subject point of view are as follows.

- Cycle with superheated vapor after compression

- Cycle with superheated vapor before compression

- Cycle with wet vapor after compression

- Cycle with dry saturated vapor after compression

- Cycle with under cooling or subcooling of the refrigerant

Vapour Compression Refrigeration System Advantages:

The Advantages of Vapor Compression Refrigeration system are as follows.

- The temperature at the evaporator section can be controlled employing regulation of expansion valve.

- It exhibits high Coefficient of Performance.

- The running cost is low because the volume circulation of the refrigerant is low in the system.

Vapour Compression Refrigeration System Disadvantages:

The disadvantages of Vapor Compression Refrigeration system are as follows.

- Make sure that there should be no leakage of refrigerant from the pipes/hose.

- Refrigerant can affect the atmosphere.

- The cost of the system is high.

Vapour Compression Refrigeration System Applications:

The applications of Vapor Compression Refrigeration system are as follows.

- It is used in domestic refrigeration for keeping the food.

- It is helpful in food processing and cold storages.

- It is useful in Industrial refrigeration for chemical processing, heating and cooling.

- It is useful in Cryogenic refrigeration, Medical refrigeration, Transport refrigeration and Electronic cooling.

This is the explanation of the Vapor Compression Refrigeration Cycle in a detailed way.

More Resources:

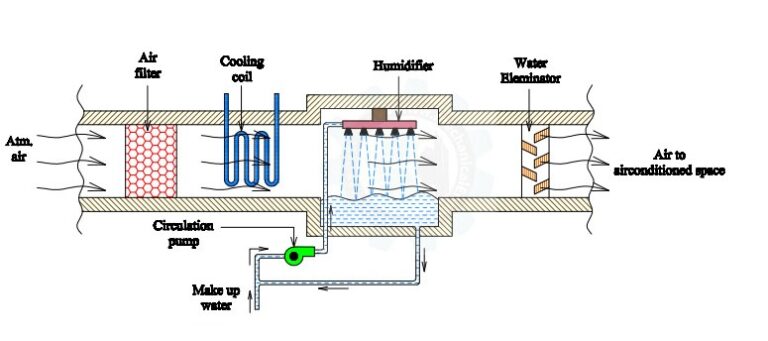

Summer Air Conditioning and Winter Air Conditioning

References [External Links]:

- Refrigeration cycle

- (PDF) basic-refrigeration-cycle - ResearchGate