Components of Robot: Advantages, Disadvantages, and Applications [PDF]

A robot is derived from the Czech word ‘robota’ which means slave labor and was invented by Karel Capek in 1917. Therefore, In this article, I will be explaining the Components of Robot along with its Advantages, Disadvantages, and Applications.

Definition of Robot:

The Robot is defined as A "re-programmable, multi-functional manipulator designed to move parts, materials, tools or specialized devices through various programmed motions for the performance of a variety of tasks”.

Asimov (1970) in his three laws of robotics explained robots as harmless and were in the control of humans.

These are invented in order to replace humans where there is a value for human life i.e. in wars, fire fighting, etc.

The study of Robots is called robotics.

Components of Robot:

The basic components of a Robot are

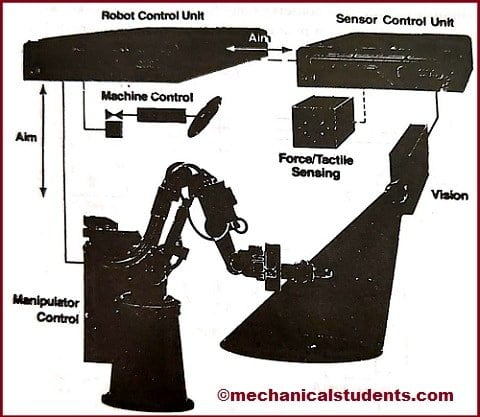

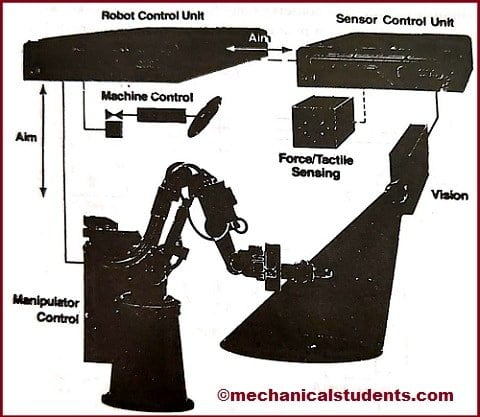

- Manipulator

- Power Supply

- A Robot Control Unit (Control System)

- Sensor Control Unit

These components may be assembled as one integral unit or separated into individual components which are connected by a hydraulic, pneumatic, or electrical source.

An Explanation for the Components of a Robot:

The explanation of robotic components are as follows.

1. Manipulator:

The manipulator is an assembly of various axes that is capable of providing motion in various directions.

The manipulator essentially consists of Base, Shoulder swivel, Elbow extension, and wrist. [Understanding Purpose: Considering manipulator as a human being then legs of human is nothing but the base of a manipulator, Shoulder swivel, Elbow extension, and wrist are similar to humans.]

The “wrist " located at the end of the robot arm has 1 to 3 DOF (Degree of Freedom), depending on the model made.

The wrist of the robot has 3 degrees of freedom i.e. pitch, yaw, and roll axes which were shown in the figure of a manipulator.

The manipulator is powered by pneumatic cylinders or hydraulic cylinders or hydraulic motors to power the various axes of motion.

Feedback devices are used to measure the position and velocity of various axes of motion and send this information to the control systems for use in coordinating the robot motions.

The duty of Feedback devices is to send feedback to the Robot controller taken from the work region.

The Robot controller will check the (actual amount of work to be done) to the (work has done on the workpiece) and calculate the difference. This difference is again given to the manipulator to do the remaining work.

2. Power Supply:

- The power supply is the source of energy used to regulate the robot's drive mechanisms.

- The energy comes from three sources are Electric, Hydraulic, and Pneumatic.

- Electric drives have a high degree of accuracy and repeatability.

- They also offer a wide range of payload capacity, accompanied by an equally wide range of costs.

- Hydraulic drives, are the most popular nowadays and have high payload capacities which are relatively easy to maintain.

- They are, however, rather expensive and not as accurate as either the electric or pneumatic drives.

- Pneumatic drives, although limited to smaller payloads, are relatively inexpensive but they are fast and reliable.

3. A Robot Control System (RCS):

- The Robot Control system acts as the brain of the robot. It coordinates and sequences the motion of the various axes of the robot and provides communication with external devices and machines.

- Programs may be written in AML (A Manufacturing Language), which is a high-level language developed specifically for industrial robot applications.

- The operator interacts with the RCS(Robot Control system) through a standard video terminal.

- The terminal is used to create and edit programs, enter robotic commands and execute programs, and generate data points during the robot training phase.

The sensors used in this system are vision sensor, Prismatic sensor etc.

Vision Sensor or Vision Sensing:

Adaptive control for robots may be defined as the modification in its behavior such that it will adjust to the changes in it's working environment.

The main advantage of adaptive control lies in its flexibility, the ability to change the control program easily to a new function, or adjust to new parts as the need arises.

The two components that provide the Adaptive control are

- Robot Control Unit (RCU)

- Sensor Control Unit (SCU)

The Robot Controlled Unit was already discussed…Now let's discuss the Sensor Control Unit (SCU).

4. Sensor Control Unit (SCU):

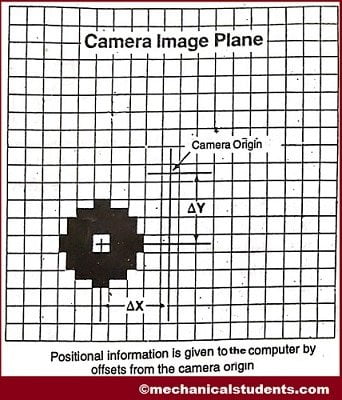

The Sensor Control Unit (SCU) provides visual information about the scene to be analyzed. It takes the information about the performance of each camera, analysis the image, and transposes that information to the robot's coordinate system.

An image of an object comes through the camera lens and falls on an image plane inside the camera.

The most useful camera for machine vision is the solid-state matrix array camera, which was designed for military space use.

This camera consists of grid light-sensitive elements called pixels or picture elements. The information from this grid is acquired by scanning rapidly the entire field, line by line.

The varying light intensities associated with each pixel are then translated into varying voltage levels and transmit to the interface electronics.

Adaptive control of a robot eliminates the need for accurate fixturing of workpieces, precise fabrication tolerances of equipment, and accurate teaching of the coordinate data.

The 3D coordinate information is analyzed by the Sensor Control Unit (SCU) and sent it to the RCU (Robot Control Unit) so that action can be taken by the control unit and deliver it to the manipulator.

This is the detailed explanation for the Components of Robot. I hope you had understood. Let's see the advantages and disadvantages of Robot along with its applications.

Advantages of Robot:

The advantages of Robot are as follows.

- It is reliable to perform repetitive activities without losing interest like humans.

- They can handle heavy loads in a single path or a zig-zag path.

- They are used in industries to do the work continuously and also used to explore the space.

- Robots are used to reduce labor.

- Consistency will be maintained throughout the work which is not possible by humans i.e. human can take rest after doing work whereas the Robot can do the work Consistently.

- Robots work with Precision and that's the reason they are used in various industries.

Disadvantages of Robot:

The disadvantages of Robot are as follows.

- The main disadvantage of a robot is the loss of jobs of various technicians, laborers, and Engineers.

- It continuously uses a power supply to work.

- The maintenance and repair costs of robots are more.

- High skilled engineers are required to write codes, change codes, and run the program depending upon availability.

- If everything can be done by the robot, the health hazards for humans increases i.e. increase in obesity for sitting continuously without doing any work and depending only on the machine, etc.

Applications of Robot:

The applications of Robot are as follows.

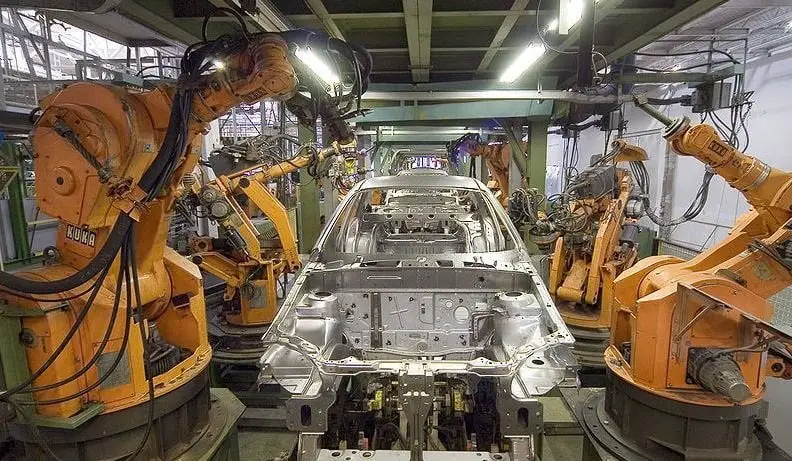

- Robots in Automotive Manufacturing

- Robots in Spray Painting

- Robotic Assembly and Part transfer.

- Robots in Fire Fighting

- Robotic welding

- Autonomous mobile robot weeding a field

- Medical and Military Robots.

This is the detailed explanation of Robots. If you have any doubts, ask us and we will reply soon.

Some FAQ on the topic-Components of Robot:

What are the main types of robots?

What are the main components of robots?

What are the components of a robotic arm?

How many axes does a Scara robot have?

More Resources:

Electrochemical Machining

References [External Links]:

- An Introduction to Robotics-Ohio University