Milling Machine: Definition, Parts, Types, Operations, Application, Advantages and Disadvantages [PDF]

Milling Machine is a machine tool that is used to remove the material from flat and irregular surfaces. It is generally used to create gears.

The various types of machine tools are

In today's session, we will discuss Definition, Parts, Types, Application, Advantages, and Disadvantages of Milling Machine in detail.

So now let's start with the Definition of Milling Machine.

Definition of Milling Machine:

Milling Machine is a machine tool that uses a multi-point cutting tool for removing a layer of material in the form of grooves from the surface of the workpiece.

Some Key Points on Milling Machine:

- Machining of flat surfaces, Slots, pockets, keyways, and profile.

- The Surface finish achievable is (RA value in microns ):3.2

- The Cutting tools used are made up of HSS CARBIDE material.

- The Milling Machine can be performed by both conventional and CNC type.

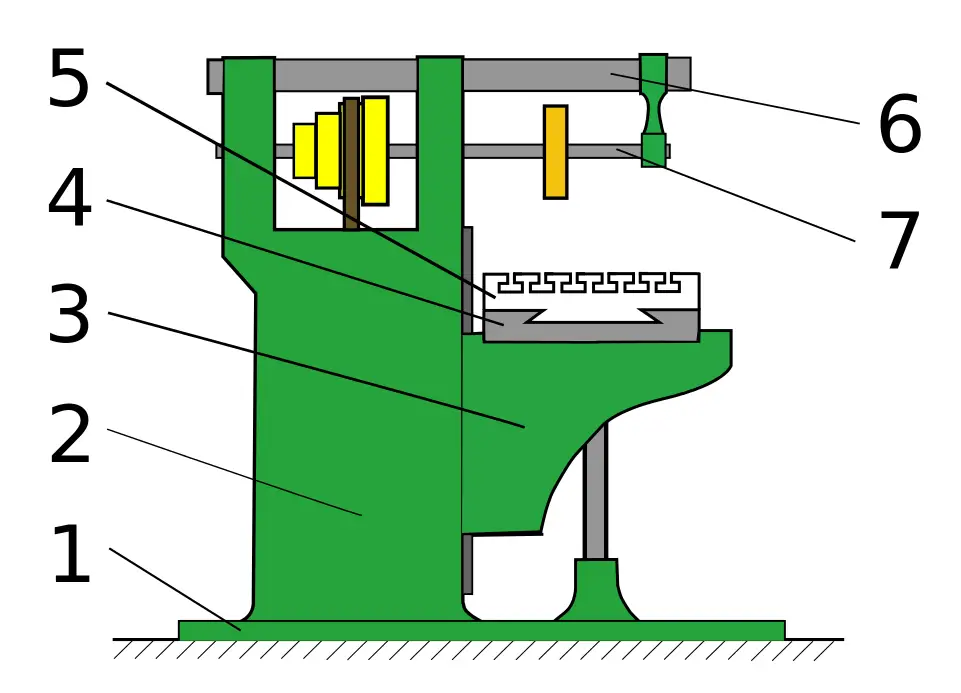

Parts of Horizontal Milling Machine:

The Parts of the Horizontal Milling Machine are as follows.

- Base

- Column

- Knee

- Saddle

- Table

- Overarm

- Arbor Support and

- Elevating Screw.

An explanation for the parts of horizontal milling machine:

The explanation for the parts of horizontal milling machine is as follows.

Base:

It provides support to all the parts of the machine and which can absorb the vibrations induced during milling operation and also acts as a reservoir for the cutting fluids.

Column:

The column is the main supporting frame mounted vertically on one side of the base which is box-shaped and has all the mechanisms inside it for the spindle and table feed.

Knee:

- The knee is a rigid casting mounted on the front face of the column.

- The knee moves vertically along the guideways and this movement adjusts the distance between the job mounted on the table and the cutter.

- This adjustment can be done manually or automatically by operating the elevating screw provided below the knee.

Saddle:

The saddle rests on the knee and it moves transversely, i.e., crosswise (in or out) on guideways provided on the knee.

Table:

The table made of cast iron rests in the saddle on guideways and provides support to the work.

The worktable and hence the job fitted on it is given motions in three directions:

- Cross or transverse motion(in or out) provided by moving the saddle in relation to the knee.

- Vertical movement (up and down) provided by raising or lowering the knee.

- Longitudinal motion(back and forth) provided by hand wheel fitted on the side of the feed screw.

Overarm:

The Overarm is mounted at the top of the column and is the support for the arbor.

Arbor Support:

The arbor is a machined shaft that holds and drives the cutters. The arbor support is fitted to the Overarm and can be clamped at any location. Its function is to support various arbors.

Elevating screw:

The upward movement and the downward movement to the knee and the table can be given by means of elevating screw which is operated either manually or Automatic.

Types of Milling Machine:

The different types of Milling Machines are as follows.

- Horizontal milling machine.

- Vertical milling machine.

- Column and Knee Type Milling Machine

- Simplex milling machine.

- Duplex milling machine

- Triplex milling machine.

- Fixed Bed Type milling machine.

- Universal Milling Machine.

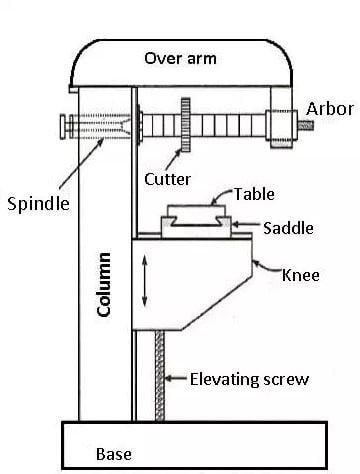

Horizontal Milling Machine:

A horizontal Milling machine is a type of machine which can hold and rotates the spindle in the horizontal orientation which can remove the material from the surface of a stationary workpiece.

Horizontal Milling machine have shorter and thicker cutting tools.

Vertical Milling Machine:

A Vertical Milling machine is a type of machine which can hold and rotates the spindle in the vertical orientation which can remove the material from the surface of a stationary workpiece.

Vertical Milling machine have longer and thinner cutting tools.

Column and Knee Type Milling Machine:

In this column and knee type milling machine, a vertical column is attched to the bed which consists of gear drives that can rotate saddle and knee.

A knee is situated on the vertical column which can move up and down by means of elevating screw which can raise or lower the workpiece.

A saddle is placed on the top of the knee which can move in transverse directions and which vcan make the worktable to move along it.

Simplex Milling Machine:

In this simplex milling machine, the spindle or the spindle head can travel only in one direction, and mostly it can travel in the vertical direction only.

Duplex Milling Machine:

In this duplex milling machine, the spindle or the spindle head can travel in two directions i.e. horizontal and vertical directions.

Triplex Milling Machine:

In this triplex milling machine, the spindle or the spindle head can travel in three directions i.e. along X-axis, Y-axis and Z-axis.

Fixed Bed Type Milling Machine:

As the name indicates that the bed of the machine is fixed type and there is no arrangement of saddle and knee in transverse and vertical directions.

And the worktable is situated on the fixed bed.

The spindle is mounted in a spindle head which can move along horizontal and vertical directions to perform machining operation.

Universal Milling Machine:

It is similar to horizontal milling machine but there is an arrangement of swing up the table upto 45 degrees in X and Y directions.

These are the different types of Milling machines that can be used to perform various operations.

Milling Machine Operations:

These are the operations we can perform on a Milling Machine:

- Face Milling Operation

- Slot or Slab Milling Operation

- End Milling Operation

- Angular Milling Operation

- Side and Face Milling Operation

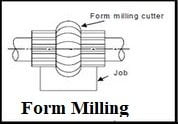

- Form Milling Operation

- Slitting Operation

- Keyway Milling Operation

- Gear Cutting Operation

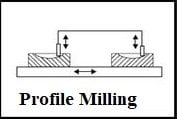

- Profile Milling Operation

- Helical Milling Operation

The detailed explanation for the different types of milling operations is as follows.

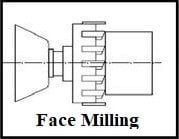

Face Milling Operations:

If the Milling Operation is used for removing a layer of material from a complete surface of the workpiece is called a face Milling Operations.

Slot/Slab Milling Operations:

If the Milling Operation is used for producing slots in the component is called a slab or slot Milling Operations.

In general, both the types of milling operations will be performed by using both the type of milling cutters but it is preferable to perform face Milling Operation with end mill cutter and slab Milling Operations with a peripheral milling cutter.

When peripheral milling cutter is used for performing the Milling Operation there are two methods of milling will be used.

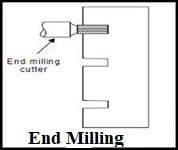

End Milling Operations:

By end mill cutter, we can perform End Milling Operation.

For machining slots, pockets, keyway, etc

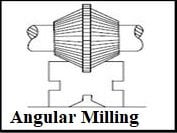

Angular Milling Operations:

Angle milling cutter or fitting spindle head in vertical.

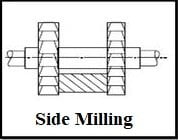

Side and Face Milling Operations:

By side and face milling cutter, we can perform this operation.

Form Milling Operations:

By form milling cutter, we can perform this operation.

Slitting Operation:

By the metal, slit saw.

Keyway Milling Operation:

By plain milling cutter or end milling cutter, we can perform this operation.

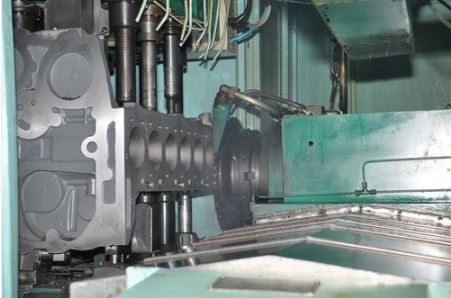

Gear Cutting Operation:

By using Formed tooth cutter with dividing head.

Profile Milling Operation:

By a ball nose cutter on CNC Milling machine (Both 3D and 2D profiles)

Helical Milling Operation:

Produces grooves and prosperity of cylindrical work.

These Milling Operations are performed on various milling machines.

Applications of Milling Machine:

The applications of Milling Machine are as follows.

- The milling machine is used for making various types of gears.

- It is generally used to produce slot or groove in work pieces.

- It can able to machine flat surface and irregular surfaces too.

- It is used in industries to produce complex shapes.

- It is used in Institutions or colleges to conduct lab tests on milling machine.

Advantages of Milling Machine:

The advantages of Milling Machine are as follows.

- It can able to produce complex shapes with multi-point cutting tool very easily.

- The production rate is also high.

- The lead time will be reduced.

- High accuracy of the component can be obtained.

- With the help of various milling cutters, the operator is able to do the work fastly.

- It can also be controlled by CNC machines.

Disadvantages of Milling Machine:

The disadvantages of Milling Machine are as follows.

- It can consume more electricity bduring operation.

- It requires skilled operator to perfom milling operations accurately.

Some FAQ's on this Topic:

What are the Milling Operations Performed on Milling Machines?

Slot or Slab Milling Operation

End Milling Operation

Side and Face Milling Operation

Form Milling Operation

Slitting Operation

Angular Milling Operation

Keyway Milling Operation

Gear Cutting Operation

Profile Milling Operation

Helical Milling Operation

How many types of Milling Machines are there?

Vertical milling machine.

Plain milling machines.

Ram type milling machine.

Universal milling machine.

Bed Type milling machine.

What are the Parts of Horizontal Milling Machine?

Column

Knee

Saddle

Table

Overarm

Arbor Support and

Elevating Screw.

What is a universal milling machine?

What is milling used for?

More Resources:

Drilling Machine

Radial Drilling Machine

Lathe Machine

Surface Grinding Machine

References [External Link]:

- Different Types of Machining Operations and the Machining

- MILLING MACHINE OPERATIONS