Electric Arc Furnace: Definition, Types, Construction, Working, Application, Advantages, and Disadvantages [PDF & Notes]

Today in this article we will be going to see the overview of Electric Arc Furnace, which includes it's definition, types, construction details, working principle, applications, advantages, and disadvantages. So let's dive into the paper right now.

Electric Arc Furnace Definition:

It is an extremely hot enclosed region, where heat is produced using electrodes for melting certain materials such as steel (scrap) without changing the electrochemical properties of the material(metal).

The electric arc produced between the electrodes and the metal is used for melting the metal(scrap).

Types of Furnace:

- DC Electric Arc Furnace

- AC Electric Arc Furnace

The explanation for the types of furnace are as follows.

1.DC Electric Arc Furnace:

DC Electric furnace is advanced of AC Electric Furnace. The DC furnace system has only one graphite electrode and the remaining electrodes are embedded at the bottom of the furnace.

In DC Electric Arc Furnace, Current flows from Cathode to Anode.

Advantages of DC Electric Furnace:

- In this process, the decrease in electrode consumption is about 50%.

- The hearth life can be increased.

- The decrease in power consumption by 5%-10%.

2.AC Electric Arc Furnace:

In the AC Electric Arc Furnace, three graphite electrodes are used which acts as a cathode and the scrap itself acts as Anode. I will elaborate on this process below.

Construction of AC Electric Arc Furnace:

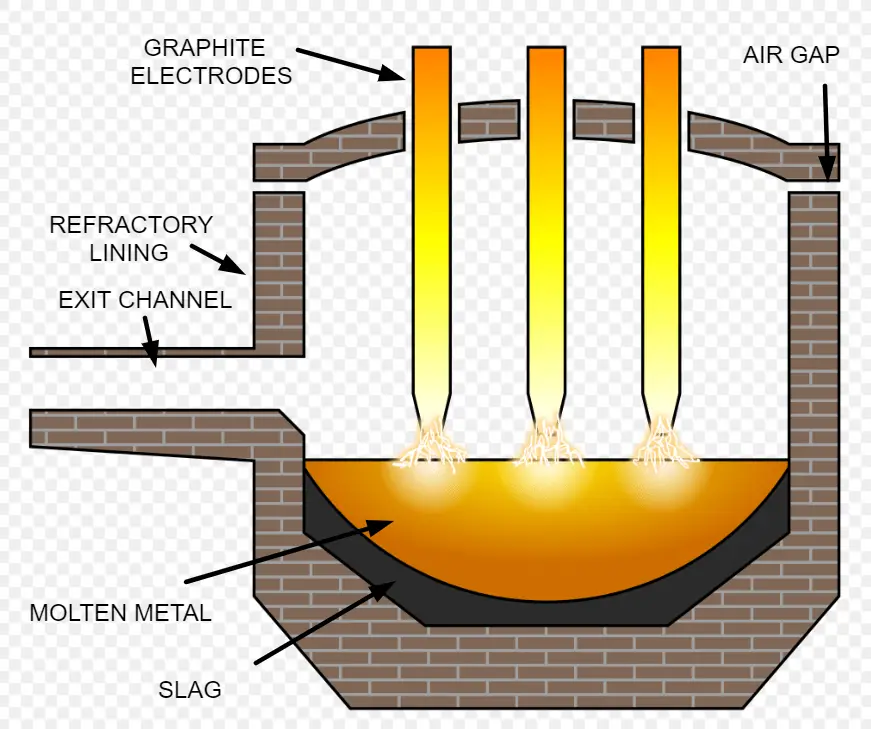

- The main parts of the electric furnace are the roof, hearth (lower part of a furnace, where molten metal is collected), electrodes, and sidewalls.

- The roof consists of three holes through which the electrodes are inserted. The hearth includes metal and slag.

- The tilting mechanism is used to pour the slag from the container before the pure form of iron is to be taken out.

- In AC electric furnace, electrodes are three in number and are in circular cross-section. Graphite is used as electrodes because of its high electrical conductivity.

- The electrodes positioning system helps to raise and lower the electrodes automatically. The electrodes get highly oxidized when the current density is high.

Working of AC Electric Arc Furnace:

When the power supply is given to the cathode and anode, the ions start transferring from cathode to anode & anode to cathode simultaneously and due to this, heat is generated which can melt the Pig iron and scrap.

The spark is generated at the electrode due to the collision of ions when transferring between cathode and anode respectively. The spark generated is used to melt the metal quickly.

After the arc is shielded by electrodes, the voltage is increased for speeding up the melting process.

During melting, the impurities present in the molten pool deposits on the surface as a slag. Other impurities will be escaped out from the container. In this process, carbon, silicon, and manganese get oxidized and the reactions are as follows.

2C+O2→ 2CO

Si + O2→ SiO2

2mn + O2→ 2mno

The oxides of Manganese(mn) and Silicon(Si) reacts with each other to form a slag and Carbon is reacted with oxygen to form Carbon monoxide(CO). The CO burns in the container itself.

mno+SiO2→ mnSiO3

Here mnSiO3 is a slag.

The slag formed is removed from the container by tilting it one side down and the rest of the material is the purest form of steel which is to be taken out from the container.

Thus by the use of Electric Arc Furnace, we can get the purest form of steel.

This is the detailed working of Electric Arc Furnace. Now let's discuss the advantages and disadvantages of it.

Advantages of Electric Arc Furnace:

The advantages of Electric Arc Furnace are as follows.

- The process of Electric Arc Furnace is better than the usage of the conventional process i.e. making steel from ores.

- By the usage of this process, we can get a pure form of steel from the scrap.

DisAdvantages of Electric Arc Furnace:

The disadvantages of Electric Arc Furnace are as follows.

- Production of slag will be more in this process.

- heavy trucks are needed for scrap handling

- Due to the presence of dynamic quality of the arc furnace load, power systems may require technical measures to maintain the quality of power.

Applications of Electric Arc Furnace:

The applications of Electric Arc Furnace are as follows.

- The arc furnaces are used to produce mini steel structural bars and steel rods.

More Resources:

Electric Arc Welding

Electrical Fuel Pump

References [External Links]:

- Furnaces and Boilers | Department of Energy

- Arc furnace | metallurgy | Britannica