Cone Clutch: Parts, Working Principle, Advantages, Disadvantages, and Applications [PDF]

The function of the clutch is to engage and disengage the power transmission from the engine to the gearbox whereas, in the cone clutch, normal forces are acting on the contact surfaces which are larger than the axial forces compared to a single plate clutch.

As we have different types of friction clutches and cone clutch is one of them and the other types of clutches are as follows:

- Single Plate Clutch

- Multi Plate Clutch

- Centrifugal Clutch

- Electromagnetic Clutch

Let’s discuss about Cone Clutch in detail.

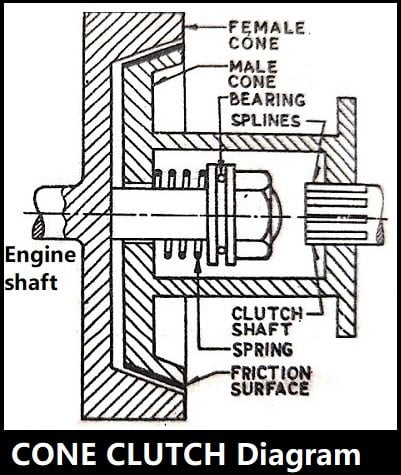

Line Diagram of Cone Clutch:

Parts of a Cone Clutch:

The parts of Cone Clutch are as follows:

- Female Cone

- Male Cone

- Bearing

- Splines

- Springs

- Clutch Shaft

- Friction Lining

Explanation for the parts of Cone Clutch:

#1 Female Cone or Outer Cone:

It is the part of the cone clutch in which, male cone will be engaged with the female cone to transmit the power. The outer cone is always under rotation because it is connected to the flywheel.

#2 Male Cone or Inner Cone:

Inner cone is also known as Male cone which is connected to the shaft of the gearbox.

There is a frictional lining on the outer part of the inner cone which allows frictional contact between the male cone and female cone.

To disengage the power, the driver has to press the clutch pedal so that male cone will be disengaged from the female cone.

#3 Bearing:

The bearing rides on the clutch spring for proper engagement of male cone with the female cone.

#4 Splines:

These are teeth or ridges on the driving shaft that mesh with grooves so as to transfer the torque.

#5 Springs:

These springs act as a support for the engagement and disengagement of male cone with the female cone.

#6 Clutch Shaft:

It is connected to the gear box so as to transmit the power from the engine via clutch.

#7 Friction Lining:

It is to be placed on the inside surface of outer cone and outside surface of inner cone so that when there is an engagement between male and female cone, there exists a contact among them for the transmission of power.

Working Principle of a Cone Clutch:

In this type of clutches, the contact surfaces are in the form of cones as shown in the above line diagram of Cone Clutch.

The cone clutch arrangement consists of two cones. One is the male cone and the other is the female cone.

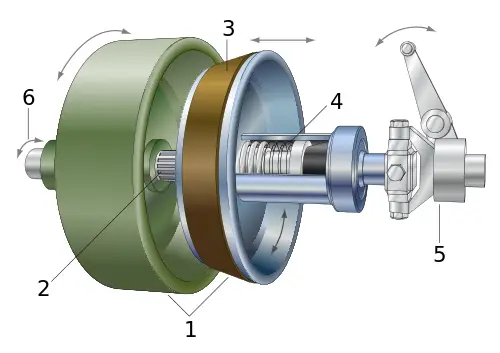

2. Shaft: the male cone is sliding on splines

3. Friction material: usually on female cone, here on male cone

4. Spring: brings the male cone back after using the clutch control

5. Clutch control: separating both cones by pressing

6. Rotating direction: both direction of the axis are possible

Engagement of Cone Clutch:

The basic principle is when the clutch is in engaged position power is transmitted to the gearbox and when the clutch is in the disengaged position, power will not transmit.

During the engagement of cone clutch, the male cone is fully present inside the female cone such that the friction surfaces are in complete contact and this contact can be done by means of springs which keep the male cone press all the time.

Due to this contact, the torque is transmitted from the engine via the flywheel and the male cone to the splined gearbox shaft.

Dis-Engagement of Cone Clutch:

For disengaging the clutch, the lever system is used which can be operated by means of clutch pedal was used to pull out the male cone from the female cone.

Note:

When you apply the force on the pedal, it means that you are going to disengage the clutch shaft and when you are removing the pressure from the clutch pedal, it indicates the clutch is in engagement and thereby the power will be transmitted.

Advantages of Cone Clutch:

The only advantage of the cone clutch is the application of normal forces acting on the contact surface is larger than the axial force compared to the single-plate clutch.

Disadvantages of Cone Clutch:

Here are some disadvantages of Cone-Clutch:

- If the angle of the cone is made lesser than 20°, then the male cone tends to join the female cone and it becomes difficult to disengage the clutch.

- The wear due to contact surfaces of the cone results in a considerable amount of the axial movement of the male cone.

Applications of Cone Clutch:

Following are the applications of Cone Clutch:

- Mercedes Grand Prix Rennwagen used a double cone clutch in 1914.

- A leather-double cone clutch was used in Mercedes 37/90 PS in 1914.

Some FAQ's on Cone Clutch:

Where is the cone clutch used?

What are the types of clutches?

What is the function of clutch?

More Resources:

Electromagnetic Clutch

Single Plate Clutch

Epicyclic Gearbox

References [External Links]:

- How a car clutch works | How a Car Works

- What Does the Clutch on a Car Actually Do

Media Credits:

- Clutch 3d Image: By Sweber.de - Selfmade using this sources:[1], [2], CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=4588461

- Featured image designed by the author

- Video by: Mechanic Master